Have you ever seen a metal lathe in action? It’s a fascinating tool that can shape metal into many useful items. But did you know that using a lathe can also be dangerous if you’re not trained properly? That’s where a lathe training course comes in. This course teaches you how to use a metal lathe safely.

Imagine shaping a piece of metal to create a part for your project. It sounds fun, right? But without the right safety training, accidents can happen in an instant. That’s why learning about lathe safety is so important. You don’t just want to make things; you want to make them safely.

In this article, we’ll explore what you can expect in a lathe training course. We’ll discuss important safety practices that everyone should know. Are you ready to discover how to stay safe while using a metal lathe? Let’s dive in!

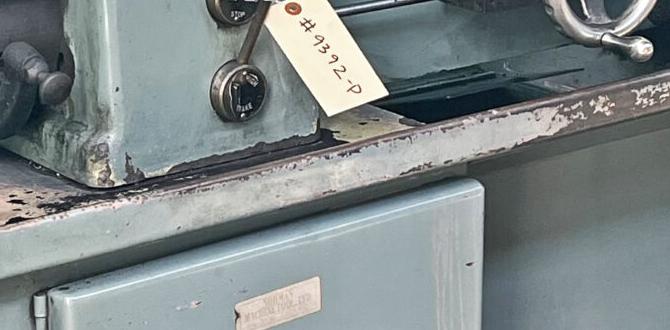

Lathe Training Course: Master Metal Lathe Safety Essentials — Introduction To Lathe Training Courses Embarking On A Lathe Training Course Is Vital For Anyone Looking To Gain Proficiency In Operating Metal Lathes. These Courses Provide Essential Knowledge Regarding Metal Lathe Safety Measures, Ensuring That Users Minimize Risks While Achieving Precision In Their Work. Importance Of Metal Lathe Safety Safety Is Paramount In Any Machining Environment, And Metal Lathe Training Emphasizes This Aspect. Participants Learn How To Handle Machines Correctly, Understand The Potential Hazards, And Apply Safety Protocols To Protect Themselves And Their Coworkers. Key Components Of A Lathe Training Course A Comprehensive Lathe Training Course Covers Various Topics Essential For Mastering The Use Of Metal Lathes, Including: 1. **Understanding Machine Components** Familiarity With The Parts Of A Lathe Helps Operators Recognize Components’ Functions And Potential Risks. 2. **Safety Protocols** Learning About Personal Protective Equipment (Ppe), Machine Safety Guards, And Emergency Stop Mechanisms Is Crucial. 3. **Operational Techniques** Proper Techniques For Loading Materials, Adjusting Speeds, And Selecting The Right Tools Contribute To Safe And Effective Lathe Operation. 4. **Maintenance And Troubleshooting** Regular Maintenance Knowledge Ensures That Machines Run Smoothly, Reducing The Chances Of Accidents Caused By Malfunctioning Equipment. Conclusion Completing A Lathe Training Course Equips Individuals With The Necessary Skills To Operate Metal Lathes Effectively And Safely. By Prioritizing Metal Lathe Safety, Companies Can Enhance Productivity And Create A Safer Workplace Environment. Investing In Training Is An Investment In Both Safety And Skill Development.

Lathe Training Course Metal Lathe Safety

Learning metal lathe safety is crucial for anyone working with lathes. This course teaches about protective gear, machine limits, and best practices. Did you know that most accidents happen due to a lack of knowledge? Participants discover how to handle tools safely and avoid common mistakes. They also grasp the importance of keeping the lathe clean and well-maintained. This knowledge not only protects the user but also ensures high-quality work. Safety first leads to confidence and success in metalworking!Importance of Lathe Training Courses

Benefits of formal training for new and experienced operators. How training enhances overall safety and efficiency.Training on a lathe is very important for everyone. It helps new and experienced operators learn safe methods. With proper training, they can work faster and better. This reduces mistakes and accidents. Benefits of these courses include:

- Improved skills and knowledge

- Better safety practices

- Greater efficiency in work

By taking time to learn, operators can ensure a safer and more productive workplace.

Why is lathe training essential?

Lathe training is essential for ensuring safety and high-quality work. It decreases risks and promotes confidence in operators.

Key Safety Protocols for Metal Lathe Operation

Essential personal protective equipment (PPE) for lathe users. Standard operating procedures to minimize accidents.Using a metal lathe can be fun, but safety comes first. Always wear necessary personal protective equipment (PPE). This includes safety goggles to protect your eyes and sturdy gloves to keep your hands safe. Don’t forget ear protection, so loud noises don’t make you feel like you’re at a rock concert!

Standard operating procedures are your best friends in the shop. Always check for loose clothing; it’s better than a wild dance with the lathe. Keep your workspace tidy to avoid accidents—nobody likes tripping over tools. Lastly, always be alert! Remember, safety first, or we’ll be singing “Oops! I Did It Again!”

| Personal Protective Equipment (PPE) | Purpose |

|---|---|

| Safety goggles | Protects eyes from flying debris |

| Gloves | Keeps hands safe from cuts |

| Ear protection | Reduces noise exposure |

By following these simple guidelines, you can enjoy your lathe training course while keeping yourself safe. Remember, a safe lathe user is a happy lathe user!

Common Hazards in Metal Lathe Work

Identifying potential risks associated with lathe operations. Strategies to mitigate these hazards effectively.Working with a metal lathe can be dangerous. You might face risks like sharp tools, moving parts, and flying debris. These hazards can lead to serious injuries. To stay safe, follow these tips:

- Wear safety glasses to protect your eyes.

- Keep hands and clothing away from moving parts.

- Secure loose items, so they don’t get caught in the machine.

- Always follow instructions and wear proper gear.

Being aware of these dangers helps keep you safe while working.

What are some common hazards in metal lathe work?

Common hazards include sharp tools, rotating parts, and debris. Workers should be aware of these risks to prevent accidents.

Essential Skills Covered in Lathe Training Courses

Handson experience with various lathe operations. Instruction on routine maintenance and troubleshooting.A lathe training course teaches important skills for working with metal lathes. Students get hands-on experience with different lathe operations. They learn how to shape and cut metal safely. Alongside precise work, they also discover how to perform routine maintenance. This includes checking parts and fixing common issues. These skills ensure safe and efficient machine use. Here’s what students gain:

- Safe operation of lathes

- Cutting techniques

- Basic maintenance skills

- Troubleshooting problems

What skills will I learn in a lathe training course?

In a lathe training course, you learn how to operate machines safely, maintain them, and troubleshoot issues.

Developing a Safety Culture in the Workshop

Encouraging communication and reporting of safety concerns. Implementing regular safety audits and refresher courses.In a workshop, talking about safety is super important. Encourage everyone to speak up about their concerns. Open discussions can prevent accidents before they happen. Regular safety audits are key too; they help spot issues before you trip over them! How often should you train? Consider hosting refresher courses every few months. They keep everyone sharp. Remember, it’s not just about the machines; it’s about us. Let’s keep it safe—and maybe even make it fun with safety games!

| Action | Frequency |

|---|---|

| Safety Audits | Quarterly |

| Refresher Courses | Every 6 Months |

Resources for Further Learning on Lathe Safety

Recommended books, websites, and organizations for lathe safety information. Online courses and training platforms for enhanced learning options.Learning about lathe safety can be fun! There are many resources available. Here are some great options:

- Books: Look for titles on lathe operation and safety. Books by experts can provide valuable tips.

- Websites: Check out sites like OSHA and training organizations for safety guides.

- Online Courses: Platforms like Coursera and Udemy offer courses on metal lathe safety.

- Organizations: Join local maker spaces or trade schools. They often have hands-on training and safety info.

These resources can help keep you safe while you learn!

What are some good online platforms for lathe safety courses?

You can find useful courses on Coursera, Udemy, and Skillshare. They offer a variety of lessons about lathe safety!

Conclusion

In summary, a lathe training course teaches you how to use metal lathes safely. You learn about protective gear, proper machine operation, and maintenance tips. Safety is key to preventing injuries. We encourage you to sign up for a course to improve your skills. For more information, check local workshops or online resources about lathe safety. Happy learning!FAQs

What Are The Essential Personal Protective Equipment (Ppe) Requirements For Operating A Metal Lathe Safely?When you use a metal lathe, you need to wear certain safety gear. First, put on safety glasses to protect your eyes from flying bits of metal. Next, wear ear protection to keep your ears safe from loud noises. It’s also important to wear gloves to protect your hands but make sure they are tight-fitting to avoid getting caught. Lastly, sturdy shoes will help keep your feet safe from falling tools.

How Can You Identify And Mitigate Hazards Present In The Lathe Workspace Before Beginning Your Machining Tasks?To find hazards in the lathe workspace, look for things that can cause accidents. Check for loose parts, spills, or sharp tools. Make sure to clean up any mess and keep tools put away. Always wear safety gear, like goggles and gloves, to protect yourself. Finally, if something doesn’t seem safe, ask for help before you start working.

What Are The Steps For Proper Setup And Adjustment Of A Metal Lathe To Ensure Safe Operation?To set up a metal lathe safely, start by cleaning the machine. Then, check that all parts are tight and working well. Adjust the speed and tools according to what you need. Always wear safety gear like goggles and gloves. Finally, keep your hands away from moving parts while it runs.

What Are Some Common Operational Mistakes That Can Lead To Accidents When Using A Metal Lathe, And How Can They Be Avoided?Some common mistakes when using a metal lathe include not wearing safety gear, ignoring machine instructions, and not checking tool setups. You should always wear safety goggles to protect your eyes. Always read the machine’s instructions before starting. Make sure the tools are set up correctly every time. This helps keep us safe while we work.

How Should You Respond In Case Of An Emergency Or Accident While Operating A Metal Lathe?If there’s an emergency while using a metal lathe, you should stay calm. First, turn off the machine quickly. Next, check yourself and others for any injuries. If someone is hurt, get help right away. Always make sure to tell an adult about what happened.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Personal Protective Equipment (Ppe) Requirements For Operating A Metal Lathe Safely? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, you need to wear certain safety gear. First, put on safety glasses to protect your eyes from flying bits of metal. Next, wear ear protection to keep your ears safe from loud noises. It’s also important to wear gloves to protect your hands but make sure they are tight-fitting to avoid getting caught. Lastly, sturdy shoes will help keep your feet safe from falling tools.”}},{“@type”: “Question”,”name”: “How Can You Identify And Mitigate Hazards Present In The Lathe Workspace Before Beginning Your Machining Tasks? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find hazards in the lathe workspace, look for things that can cause accidents. Check for loose parts, spills, or sharp tools. Make sure to clean up any mess and keep tools put away. Always wear safety gear, like goggles and gloves, to protect yourself. Finally, if something doesn’t seem safe, ask for help before you start working.”}},{“@type”: “Question”,”name”: “What Are The Steps For Proper Setup And Adjustment Of A Metal Lathe To Ensure Safe Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe safely, start by cleaning the machine. Then, check that all parts are tight and working well. Adjust the speed and tools according to what you need. Always wear safety gear like goggles and gloves. Finally, keep your hands away from moving parts while it runs.”}},{“@type”: “Question”,”name”: “What Are Some Common Operational Mistakes That Can Lead To Accidents When Using A Metal Lathe, And How Can They Be Avoided? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common mistakes when using a metal lathe include not wearing safety gear, ignoring machine instructions, and not checking tool setups. You should always wear safety goggles to protect your eyes. Always read the machine’s instructions before starting. Make sure the tools are set up correctly every time. This helps keep us safe while we work.”}},{“@type”: “Question”,”name”: “How Should You Respond In Case Of An Emergency Or Accident While Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If there’s an emergency while using a metal lathe, you should stay calm. First, turn off the machine quickly. Next, check yourself and others for any injuries. If someone is hurt, get help right away. Always make sure to tell an adult about what happened.”}}]}