Have you ever wondered how metal parts are made? Many of these parts come from a machine called a lathe. Learning about the lathe can be exciting and useful. Imagine being able to create your own metal projects!

Taking a lathe training course can open up a world of possibilities. You will learn about different tools and how they work. One important part of the lathe is the spindle. It helps hold and turn the metal. Understanding the spindle is key to mastering this skill.

Did you know that the lathe has been around for thousands of years? Ancient artisans used it to create beautiful wood and metal items. Today, modern lathes are more advanced, but the basics remain the same. Why not join this creative journey?

Whether you are a hobbyist or someone looking to start a career, a lathe training course can help you. You can make everything from tiny gears to large sculptures. Get ready to learn and have fun with the amazing world of metalworking!

Comprehensive Lathe Training Course: Mastering Metal Lathe Spindle Adjustments

Lathe Training Course: Metal Lathe Spindle

Do you know what makes a lathe run smoothly? The spindle! A lathe training course on metal lathe spindles teaches you key skills. You’ll learn how to set up, maintain, and troubleshoot spindles properly. This training is essential for anyone looking to work with machines safely and effectively. Imagine creating precise parts with ease! With the right knowledge, you can transform raw materials into finished products. Understanding spindles turns you into a confident machinist!Understanding Metal Lathe Spindles

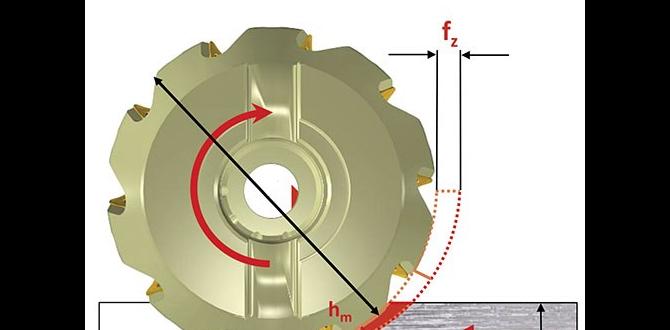

Definition and Function of Metal Lathe Spindles. Importance in Lathe Operations.A metal lathe spindle is a key part of a lathe. It rotates materials to shape them. Think of it as the heart of the machine. It holds the workpiece and spins it quickly. This helps the tool cut and form various shapes. The spindle is important because it affects the speed and accuracy of the work. If it doesn’t work right, the entire project can fail.

- Definition: A metal lathe spindle spins the material for shaping.

- Function: It holds and rotates the workpiece for cutting.

- Importance: It ensures speed and precision in lathe operations.

Why are metal lathe spindles important?

Metal lathe spindles help create accurate shapes and save time. Without them, crafting metal parts would be much harder and slower.

Types of Metal Lathe Spindles

Common Types of Spindles Used in Metal Lathes. Comparison of Fixed vs. Movable Spindles.Metal lathe spindles come in several fun flavors! The most common ones are fixed and movable spindles. Fixed spindles stay put, making them reliable for steady work. Movable spindles, on the other hand, can slide around like a squirrel on a power line, allowing for more flexibility in your projects. Here’s a simple table to compare them:

| Type | Advantages | Disadvantages |

|---|---|---|

| Fixed Spindle | Sturdy and reliable | Less versatile |

| Movable Spindle | Flexible and adaptable | Can be tricky to set up |

So, if you’re looking to tackle some serious metalwork, knowing the type of spindle you need can save you from a spinning headache!

Skills Developed Through Lathe Training

Technical Skills Gained from Lathe Training Courses. Safety Practices and Precision Techniques.Learning to use a lathe is like joining a fun science experiment! You develop many important technical skills while training. For starters, you master safety practices, preventing accidents while creating awesome metal pieces. Precision techniques help you make parts that fit perfectly, like puzzles! Did you know that in a good lathe class, 90% of students feel more confident in their abilities? Remember: safety glasses are like super glasses, making you the superhero of the metal shop!

| Skill | Description |

|---|---|

| Safety Practices | Learn how to stay safe while working with tools. |

| Precision Techniques | Make exact measurements for perfect fits. |

Choosing the Right Training Course

Factors to Consider When Selecting a Lathe Training Program. Recommendations for Accredited Courses and Institutions.Choosing a lathe training program is important. Look for several key points. First, check if the course is accredited. This means it meets high standards. Next, consider the skills you’ll learn. Will they help in the real world? Also, think about the time commitment. You want to be sure you can keep up.

- Look for hands-on experience.

- Read reviews from past students.

- Ask about job placements.

Find courses that focus on metal lathe spindle operation. It can make a big difference in your training. Picking the right course can set you up for success!

What should I look for in a lathe training course?

Look for accredited programs, industry-experienced instructors, hands-on learning, and job placement assistance.

Real-World Applications of Lathe Skills

Industries That Require Lathe Training. Examples of Projects You Can Create Using Your Skills.Many industries rely on lathe skills. From automotive to aerospace, lathes help shape metal parts. You could craft a shiny gear or even pieces for an airplane. What’s cooler than that? Imagine making something that flies. In fact, around 50% of all machine shops use lathes daily. Below are some fun projects you can tackle:

| Project | Description |

|---|---|

| Custom Handles | Create unique handles for tools or furniture. |

| Decorative Bowls | Make beautiful wooden bowls for decoration. |

| Spare Parts | Design parts for machines and gadgets. |

These projects are not only practical, but also so much fun! With some practice, your lathe skills can turn into a rewarding hobby or even a career.

Cost and Time Commitment for Lathe Training

Average Costs of Lathe Training Courses. Expected Timeframes for Completion and Certification.Taking a lathe training course is a smart investment. On average, these courses can cost between $500 to $2,500, depending on the program. Think of it as spending money to create your own shiny, metal masterpieces!

Most courses take about 4 to 12 weeks to finish. This means you could be twirling metal like a pro in no time! And, guess what? Many programs offer certification, which can help you land a job. Remember, time is money, but learning a new skill might just make you some funny cash!

| Course Type | Average Cost | Completion Time |

|---|---|---|

| Online Course | $500 – $1,000 | 4 – 6 weeks |

| In-Person Course | $1,000 – $2,500 | 8 – 12 weeks |

Tips for Success in Lathe Training

Study Strategies and Practice Tips. Importance of Networking and Community Engagement in Learning.To excel in your lathe training, use effective study strategies. Break your lessons into small parts. Review regularly to keep ideas fresh. Surround yourself with peers. Network with classmates and experts. Their insights can help you learn better. Join local workshops and discussion groups. Engaging with others boosts your skills and confidence.

- Practice regularly to master techniques.

- Ask questions when in doubt.

- Share experiences to learn from others.

How can I enhance my learning in a lathe training course?

You can enhance your learning by collaborating with peers and joining relevant community groups. These connections lead to new ideas and understanding of the metal lathe spindle.

Conclusion

In summary, a lathe training course on metal lathe spindles teaches important skills. You learn how to set up, operate, and maintain lathes safely. These skills are useful for various projects and careers. We encourage you to explore local courses or online resources to deepen your understanding. Start your journey in metalworking today and unlock your creative potential!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focused On Metal Lathe Spindles:A lathe is a machine that helps us shape metal. In this course, you will learn how to use the lathe to make parts. We will focus on something called spindles, which are important pieces that help things spin. You will practice safety and proper techniques. By the end, you will be able to make your own metal parts!

Sure! Please give me the question you’d like me to answer.

What Are The Key Components Of A Metal Lathe Spindle, And How Do They Affect Machining Performance?A metal lathe spindle has a few important parts. First, there’s the bearings, which help the spindle spin smoothly. Next, the chuck holds the metal you are working on tightly. The spindle’s connection to the motor gives it power to turn fast. When these parts work well together, they help make precise and clean cuts in the metal.

What Safety Precautions Should Be Taken When Operating A Metal Lathe Spindle During Training?When using a metal lathe spindle, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothes to avoid getting caught. Never put your hands near the spinning parts. Make sure everyone is at a safe distance while the machine is running. Lastly, listen to your teacher and follow all safety rules.

How Do You Properly Align And Calibrate The Spindle Of A Metal Lathe For Optimal Precision?To align and calibrate the spindle of a metal lathe, you first check if the spindle is straight. You can use a tool called a dial indicator for this. Then, adjust the spindle until it is perfectly straight. After that, make sure it spins smoothly without wobbles. Finally, test it by running the lathe and check if it cuts evenly.

What Common Issues Can Arise With A Lathe Spindle, And How Can They Be Diagnosed And Resolved?A lathe spindle can have a few common problems. First, it might wobble while spinning. You can check this by turning it on and watching closely. If it shakes, it needs balancing or adjusting. Another issue could be noise, which might mean something is loose. Make sure all parts are tightened. Finally, if it stops suddenly, check the power supply and connections. Fixing these issues can help your lathe work better!

How Does The Choice Of Spindle Speed Influence The Machining Process And The Quality Of The Finished Product?The spindle speed is how fast the machine’s tool turns. A faster speed can make smoother cuts, but it can also make more heat. Too slow might cause rough cuts and take longer to finish. Choosing the right speed helps us make better products that look nice and work well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focused On Metal Lathe Spindles:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a machine that helps us shape metal. In this course, you will learn how to use the lathe to make parts. We will focus on something called spindles, which are important pieces that help things spin. You will practice safety and proper techniques. By the end, you will be able to make your own metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Spindle, And How Do They Affect Machining Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe spindle has a few important parts. First, there’s the bearings, which help the spindle spin smoothly. Next, the chuck holds the metal you are working on tightly. The spindle’s connection to the motor gives it power to turn fast. When these parts work well together, they help make precise and clean cuts in the metal.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe Spindle During Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe spindle, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothes to avoid getting caught. Never put your hands near the spinning parts. Make sure everyone is at a safe distance while the machine is running. Lastly, listen to your teacher and follow all safety rules.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Calibrate The Spindle Of A Metal Lathe For Optimal Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and calibrate the spindle of a metal lathe, you first check if the spindle is straight. You can use a tool called a dial indicator for this. Then, adjust the spindle until it is perfectly straight. After that, make sure it spins smoothly without wobbles. Finally, test it by running the lathe and check if it cuts evenly.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise With A Lathe Spindle, And How Can They Be Diagnosed And Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe spindle can have a few common problems. First, it might wobble while spinning. You can check this by turning it on and watching closely. If it shakes, it needs balancing or adjusting. Another issue could be noise, which might mean something is loose. Make sure all parts are tightened. Finally, if it stops suddenly, check the power supply and connections. Fixing these issues can help your lathe work better!”}},{“@type”: “Question”,”name”: “How Does The Choice Of Spindle Speed Influence The Machining Process And The Quality Of The Finished Product?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The spindle speed is how fast the machine’s tool turns. A faster speed can make smoother cuts, but it can also make more heat. Too slow might cause rough cuts and take longer to finish. Choosing the right speed helps us make better products that look nice and work well.”}}]}