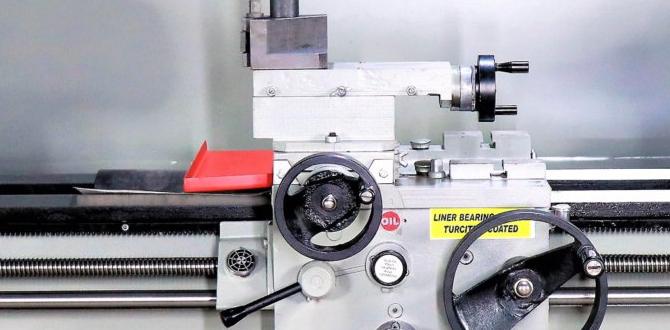

Have you ever wondered how precise metal parts are made? A lathe might be the answer! This machine is like a wizard that shapes metal into wonderful forms. But, did you know that the tailstock alignment on a metal lathe is very important for great results?

Imagine trying to draw a perfect circle. If your pencil isn’t straight, that circle won’t look right. The same thing happens with a lathe. Proper tailstock alignment ensures your projects come out smooth and just right. It’s not just about turning metal; it’s about turning dreams into reality!

If you’re thinking about a lathe training course, you’re in for a treat. Learning how to align the tailstock will improve your skills and your confidence. You will soon be making cool projects that can impress your friends or even yourself!

Essential Lathe Training Course: Metal Lathe Tailstock Alignment

Get ready to tackle metal lathe tailstock alignment like a pro! Tailstock alignment is crucial for precision in your projects. A well-aligned tailstock helps you create accurate cuts and prevents issues like tapering. Did you know that a simple misalignment can ruin hours of hard work? By taking a lathe training course, you can learn the exact steps to ensure perfect alignment every time. This skill improves your metalworking confidence and enhances your overall craftsmanship. Don’t miss out on mastering this essential technique!

Understanding the Importance of Tailstock Alignment

Explanation of tailstock’s role in lathe operations. Impact of misalignment on machining accuracy and quality.

The tailstock holds and supports the end of the workpiece on a lathe. Proper alignment is crucial. If the tailstock is off, the cutting tool may not hit the right spot. This can lead to mistakes. Here are some effects of misalignment:

- Inaccurate cuts

- Poor surface finish

- Increased tool wear

In short, keeping the tailstock aligned helps create better, more precise parts. This can save time and materials in any metal lathe project.

Why is tailstock alignment important?

Tailstock alignment is important because it ensures precise machining, resulting in better quality parts.

Tailstock Alignment: Tools and Techniques

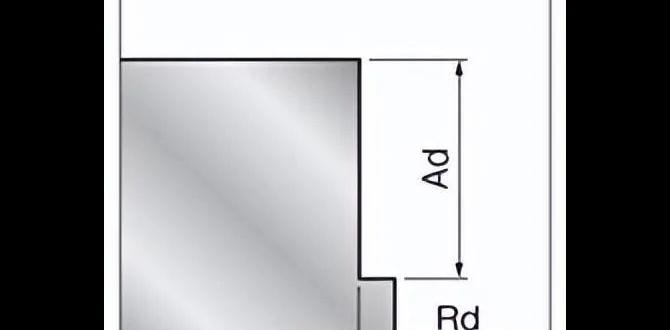

Essential tools for tailstock alignment measurement. Techniques for checking and adjusting tailstock alignment.

Measuring the tailstock alignment requires some handy tools. Key tools include a lathe alignment tool, a dial indicator, and a machinist’s square. Using these makes checking the alignment simple. Here are some techniques to follow:

- First, set up the dial indicator on the lathe’s spindle.

- Next, rotate the spindle and watch the gauge.

- If the readings are off, adjust the tailstock.

- Recheck until it lines up correctly.

Good alignment helps your work become more exact and smooth.

What tools do I need for tailstock alignment?

You need a lathe alignment tool, dial indicator, and machinist’s square to check tailstock alignment accurately.

Step-by-Step Process for Tailstock Alignment

Detailed procedures for aligning the tailstock correctly. Common pitfalls to avoid during the alignment process.

Aligning the tailstock can feel like a puzzle, but it’s easier than it sounds! First, check if the tailstock is at the right height. Use a dial indicator to see if it aligns with the spindle. Use a thick book if you need a boost! Next, secure the tailstock firmly. Avoid over-tightening; it’s not a wrestling match! Lastly, always double-check the alignment. Common pitfalls include ignoring the height difference and not testing pieces. Remember, misalignment can lead to parts that look like they were made by a toddler!

| Step | Action | Pitfall to Avoid |

|---|---|---|

| 1 | Check tailstock height | Forgetting to adjust |

| 2 | Use a dial indicator | Ignoring readings |

| 3 | Secure tailstock | Over-tightening bolts |

| 4 | Double-check alignment | Skipping this step |

Practical Exercises and Applications

Suggested exercises to practice tailstock alignment. Realworld applications of proper tailstock alignment in machining projects.

Want to master tailstock alignment? Start with fun exercises! Try aligning different tailstocks on various metal lathes. Your challenge: make it straight without going cross-eyed! Use a dial indicator for accuracy, and don’t forget to double-check. In real-world projects, proper alignment ensures your parts fit perfectly. Imagine making a fancy toy; a wobbly tailstock leads to wobbly creations! Here’s a simple table of exercises:

| Exercise | Description |

|---|---|

| Basic Alignment Test | Check alignment with a dial indicator. |

| Load Testing | Use materials of different weights. |

| Production Practice | Align tailstock while making a sample part. |

Practice these exercises regularly for smooth sailing in machining! You’ll turn your lathe skills into a masterpiece!

Troubleshooting Tailstock Alignment Issues

Identifying common problems related to tailstock alignment. Solutions and adjustments for efficient repair and maintenance.

Tailstock alignment can feel like a puzzle, but it’s often about spotting common issues. Look out for gaps or misalignment, which can cause wobbly turns. Adjusting the tailstock can make a big difference, ensuring smooth operation. If you find it tricky, don’t worry! Many users face similar problems. Just think of your lathe like a stubborn puppy—sometimes it needs a little coaxing to sit right.

| Common Problem | Solution |

|---|---|

| Tailstock wobble | Check for misalignment and tighten screws. |

| Difficulty sliding | Lubricate moving parts. |

| Offsets during cutting | Re-check alignment with a dial gauge. |

By keeping these tips in mind, you can enjoy smooth and accurate cuts. Remember, a well-aligned tailstock is a happy tailstock!

Advanced Tips for Precision Lathe Work

Best practices for achieving precision in metal lathe projects. How tailstock alignment affects overall precision in machining.

Using a lathe is like cooking; the better the ingredients, the tastier the dish! To achieve top-notch precision in metal lathe projects, keep your tailstock aligned. If it’s off, your work will resemble a wobbly cake. Check the alignment regularly and make tiny adjustments. Every millimeter counts! A misaligned tailstock can turn your masterpiece into a disaster. Remember, practice makes perfect, and soon you’ll be a lathe legend!

| Best Practices | Tips |

|---|---|

| Regular Alignment Checks | Use a dial indicator for accuracy. |

| Tool Sharpness | Keep your tools sharp like your wit! |

| Proper Speed Settings | Too fast can cause chaos! |

Resources for Continued Learning

Recommended books and online courses on lathe operations. Industry forums and communities for ongoing support and knowledge sharing.

Keep on learning even after your course ends! Grab some great books on lathe operations to sharpen your skills. There are also many online courses that can help you become a lathe master. Want some extra support? Check out industry forums and communities! They are full of knowledgeable people willing to share tips and tricks. Remember, learning is more fun when you can ask questions and make friends.

| Resource Type | Recommendations |

|---|---|

| Books | The Metal Lathe by Albert J. McCauley |

| Online Courses | Lathe Basics on Udemy |

| Forums | Practical Machinist |

Conclusion

In conclusion, a lathe training course helps you learn important skills like tailstock alignment. Proper alignment ensures precision in your metal projects. By mastering this, you improve your craftsmanship and confidence. We encourage you to practice what you’ve learned and explore more resources to deepen your understanding. Start creating today and enjoy the process of becoming a skilled machinist!

FAQs

What Are The Key Steps Involved In Aligning The Tailstock Of A Metal Lathe To Ensure Accurate Machining?

To align the tailstock on a metal lathe, first, check that it’s straight with the bed. You can do this by using a long, straight tool or a ruler. Next, adjust the tailstock so it lines up perfectly with the spindle. Finally, tighten everything so it stays in place. After that, you can test it by making a short cut to see if it is right.

How Can Improper Tailstock Alignment Affect The Quality Of The Finished Workpiece In Turning Operations?

If the tailstock isn’t lined up right, it can cause the workpiece to wobble. This makes it harder to cut smoothly. You might end up with a piece that isn’t the right shape or size. It can also make the surface feel rough. We want our finished piece to look good and feel nice!

What Tools And Methods Are Commonly Used To Check And Adjust Tailstock Alignment On A Metal Lathe?

To check and adjust the tailstock on a metal lathe, we can use a few simple tools. One common tool is a dial indicator. This tool helps us see if the tailstock is straight. We can also use a level to make sure it’s even. Sometimes, we adjust the screws on the tailstock to fix any problems we find.

Why Is It Important To Regularly Check The Tailstock Alignment During A Lathe Training Course, And What Factors Can Cause Misalignment?

It’s important to check the tailstock alignment because it keeps our work accurate. If it’s off, our projects can be wobbly or uneven. Factors like bumps, movements, or loose parts can cause misalignment. Checking helps us make better items and stay safe while using the lathe. Let’s make sure everything is lined up right!

How Does The Alignment Of The Tailstock Differ When Working With Various Materials Or Part Geometries In A Metal Lathe?

When you use a metal lathe, the tailstock needs to be aligned differently based on what you’re working with. For softer materials, like plastic, you may not need much pressure. But for harder materials, like steel, you want it to be tight and straight. If the part is long and skinny, you might adjust the tailstock to keep it steady. This helps make sure everything cuts smooth and even.