Comprehensive Lathe Training Course: Metal Lathe Wiring Diagram

Lathe Training Course: Metal Lathe Wiring Diagram Insights

Explore the essentials of a lathe training course focused on metal lathes. You’ll learn how to set up and wire a metal lathe effectively. Gain hands-on experience with wiring diagrams, ensuring safety and efficiency in your projects. Imagine being able to create precise parts for machines or tools! Understanding lathe operations can unlock a world of creativity in manufacturing. How cool is it to transform raw metal into functional products? Dive into the world of lathes today!Understanding Metal Lathes

Definition and purpose of metal lathes. Common applications in various industries.Metal lathes are machines that shape metal by spinning it against cutting tools. They help create precise parts for various things, from car engines to airplane wings. Think of a metal lathe as a giant pencil sharpener but for metal! These lathes are used in many industries, such as manufacturing and aerospace. They make everything from tiny screws to huge gears. Isn’t it cool how metal can be shaped so easily?

| Application | Industry |

|---|---|

| Car Parts | Automotive |

| Aerospace Components | Aerospace |

| Medical Devices | Healthcare |

Importance of Lathe Training Courses

Skills and knowledge needed for safe operation. Career opportunities and advancements through training.Learning how to use a lathe is as important as knowing how to ride a bike. Safety first! A lathe training course teaches essential skills for safe operation. You’ll learn to measure, cut, and shape materials without turning yourself into a human pretzel. Plus, mastering these skills can open doors to new career opportunities. Want to be a master machinist or a superhero in metalwork? This training can help you get there!

| Career Opportunities | Advancements Through Training |

|---|---|

| Machinist | Expertise in operating lathes |

| CNC Operator | Higher-paying positions |

| Manufacturing Technician | Leadership roles |

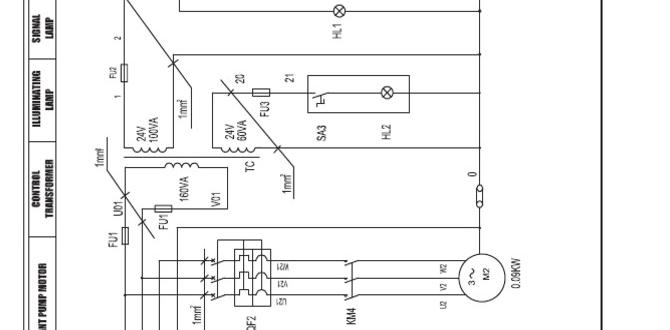

Basics of Wiring Diagrams for Lathes

Explanation of wiring diagrams and their significance. How wiring diagrams aid in troubleshooting and maintenance.A wiring diagram is like a treasure map for your lathe. It shows how everything is connected inside. Without it, you might feel lost, like a miner without a pickaxe! These diagrams help when something goes wrong. They make troubleshooting easier by pointing out the cables and parts that might need fixes. Think of it as your lathe’s instruction manual, guiding you through maintenance. Happy wiring!

| Purpose | Benefit |

|---|---|

| Shows connections | Helps in identifying issues |

| Guides maintenance | Easy repairs |

| Improves understanding | Better performance |

Interpreting Lathes Wiring Diagrams

Stepbystep guide to reading a wiring diagram. Common symbols and terminology used in diagrams.Understanding wiring diagrams can be simple and fun. Follow these steps to read them easily:

- Look for lines: They show connections.

- Identify symbols: Each symbol has a special meaning.

- Follow the path: Trace the lines from one point to another.

- Check the key: A key will explain the symbols used.

Common symbols include:

- Circle: Represents a connection point.

- Square: Indicates a device like a switch.

- Arrow: Shows the direction of electricity flow.

With practice, you’ll read wiring diagrams like a pro! Each diagram tells a story about how the lathe works. Just keep learning and exploring.

What symbols are commonly found in wiring diagrams?

Common symbols in wiring diagrams include: circles for connections, squares for devices, and arrows for electricity flow. These symbols help you understand the diagram better!

Setting Up a Lathe: Wiring Considerations

Essential electrical requirements for metal lathes. Safety precautions when wiring a lathe. “`htmlBefore you start your lathe adventure, check the essential electrical requirements. Make sure to use proper voltage and circuit breakers. It’s important to avoid any shocking surprises! Also, remember to keep the lathe area dry. A wet floor might lead to some slippery dancing, and trust me, nobody wants that!

For safety, always unplug the lathe when working on wiring. Use insulated tools and wear rubber-soled shoes. It’s like wearing superhero gear for your feet! Below is a simple table of what to consider:

| Consideration | Description |

|---|---|

| Voltage | Check the lathe’s requirements, usually 120V or 240V. |

| Circuit Breaker | Use a dedicated breaker to prevent overloads. |

| Dry Area | Keep the workspace dry to avoid accidents. |

With these tips in mind, you’re all set to wire up your lathe safely!

“`Hands-On Practice in Lathe Training Courses

Typical handson activities involved in the course. Benefits of practical experience in understanding machinery.In lathe training courses, hands-on practice is key. Students work with machines, gaining real-world skills. Typical activities include:

- Measuring metal pieces

- Setting up the lathe

- Cutting and shaping materials

- Understanding safety procedures

This practical experience helps students grasp how machines work. They learn faster and feel more confident. Knowing how to operate tools is valuable. It builds problem-solving skills and encourages teamwork. Overall, hands-on learning makes the course exciting and effective.

What are the benefits of hands-on practice in lathe training?

Hands-on practice leads to better understanding and skill development.- Boosts confidence

- Encourages creativity

- Develops important job skills

Choosing the Right Lathe Training Course

Factors to consider when selecting a training provider. Comparison of online vs. inperson training options.Choosing a lathe training course can be tough. You should think about a few important factors. Look for a training provider with good reviews. Ask about their experience and what they teach. Also, decide if you want online or in-person training:

- Online Training: Flexible schedules, learn at your pace, and access from anywhere.

- In-Person Training: Hands-on experience, direct interaction with instructors, and immediate feedback.

Each option has its perks. Consider what works best for you. Will you learn better in a classroom or from home? This choice can shape your learning journey.

What should I consider when choosing a lathe training course?

Look for reviews, verify the instructor’s experience, and check the course content.

Reviewing Common Challenges in Lathe Operation and Wiring

Frequent issues faced by beginners. Tips for overcoming wiring and operational challenges.Many beginners face challenges with lathe machines and wiring. Common problems include incorrect settings, tangled wires, and confusing diagrams. Here are tips to help:

- Check the manual before starting.

- Label wires to avoid mix-ups.

- Practice simple cuts first.

- Ask for help if you’re unsure.

Overcoming these issues can boost your confidence. Remember, practice makes perfect!

What are common problems with lathe operation?

Beginners often struggle with incorrect settings, tangled wires, and misunderstood diagrams. These factors can lead to errors and delays.

Resources for Ongoing Learning

Recommended textbooks, websites, and workshops. Communities and forums for metalworking enthusiasts and professionals.Learning does not stop after a course. Many resources can help you continue improving your skills. Here are some to check out:

- Textbooks: Look for books on metalworking and lathe techniques.

- Websites: Online courses and articles provide new methods and tips.

- Workshops: Hands-on learning in workshops helps you master your craft.

- Communities: Join forums and connect with other metalworking fans.

These resources can inspire you and add to your knowledge.

What are some good websites for metalworking?

Some great websites are YouTube for videos, Instructables for projects, and Reddit for discussions. Each offers unique tips and insights.

Building skills takes time. Utilize these resources to keep learning and growing. You’ll find new ideas and techniques that make metalworking even more exciting!

Conclusion

In conclusion, a lathe training course teaches you essential skills for using a metal lathe effectively. Understanding wiring diagrams helps you set up and troubleshoot machines. We encourage you to practice what you learn and explore more resources. Dive deeper into lathe operation and safety to enhance your skills and confidence. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Training Course And Metal Lathe Wiring Diagrams:Sure! A lathe is a machine that helps us shape metal. In a lathe training course, you learn how to use it safely and correctly. You also see wiring diagrams, which are pictures showing how to connect the machine’s parts. Learning this helps you understand how everything works together. It’s a fun way to make cool metal projects!

Sure! Please provide the question you want me to answer.

What Are The Essential Components Included In A Typical Metal Lathe Wiring Diagram?A typical metal lathe wiring diagram shows how to connect wires and parts. You will see the power supply, which gives electricity. There are switches that turn the lathe on and off. You might find a motor that makes the lathe move, and safety features to keep you safe. Each wire connects these parts so the lathe works properly.

How Can Understanding The Wiring Diagram Of A Lathe Improve Safety During Operation?Knowing the wiring diagram of a lathe helps you see how the machine works. It shows where the power comes from and how it flows. By understanding this, you can spot problems and fix them safely. It also helps you know where the emergency shut-off is, which keeps you safe. So, understanding the diagram means you can use the lathe more carefully.

What Are The Common Electrical Issues That Can Arise With Metal Lathes, And How Can A Wiring Diagram Help Troubleshoot Them?Common electrical problems with metal lathes include faulty wires, blown fuses, and motor issues. These problems can make the lathe stop working. A wiring diagram is a drawing that shows how everything connects. It helps you find where the problem is quickly. You can follow the diagram to fix the issue step by step.

In A Lathe Training Course, How Is The Wiring Diagram Integrated Into The Curriculum For Hands-On Learning?In the lathe training course, we use the wiring diagram to help you learn about the machine. You will look at the diagram and see how everything connects. Next, you will practice connecting wires on the lathe to match the diagram. This helps you understand how the machine works as you do the hands-on work. It makes learning fun and helps you remember better!

What Precautions Should Be Taken When Working With The Electrical Systems Of A Metal Lathe To Prevent Accidents?When working with a metal lathe, always wear safety goggles to protect your eyes. Keep your hands dry, and don’t touch wires with wet hands. Make sure the machine is off before you work on it. You should also unplug it to avoid any accidents. Finally, be careful around moving parts and never reach into the machine while it’s running.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Training Course And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. In a lathe training course, you learn how to use it safely and correctly. You also see wiring diagrams, which are pictures showing how to connect the machine’s parts. Learning this helps you understand how everything works together. It’s a fun way to make cool metal projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Included In A Typical Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A typical metal lathe wiring diagram shows how to connect wires and parts. You will see the power supply, which gives electricity. There are switches that turn the lathe on and off. You might find a motor that makes the lathe move, and safety features to keep you safe. Each wire connects these parts so the lathe works properly.”}},{“@type”: “Question”,”name”: “How Can Understanding The Wiring Diagram Of A Lathe Improve Safety During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Knowing the wiring diagram of a lathe helps you see how the machine works. It shows where the power comes from and how it flows. By understanding this, you can spot problems and fix them safely. It also helps you know where the emergency shut-off is, which keeps you safe. So, understanding the diagram means you can use the lathe more carefully.”}},{“@type”: “Question”,”name”: “What Are The Common Electrical Issues That Can Arise With Metal Lathes, And How Can A Wiring Diagram Help Troubleshoot Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common electrical problems with metal lathes include faulty wires, blown fuses, and motor issues. These problems can make the lathe stop working. A wiring diagram is a drawing that shows how everything connects. It helps you find where the problem is quickly. You can follow the diagram to fix the issue step by step.”}},{“@type”: “Question”,”name”: “In A Lathe Training Course, How Is The Wiring Diagram Integrated Into The Curriculum For Hands-On Learning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the lathe training course, we use the wiring diagram to help you learn about the machine. You will look at the diagram and see how everything connects. Next, you will practice connecting wires on the lathe to match the diagram. This helps you understand how the machine works as you do the hands-on work. It makes learning fun and helps you remember better!”}},{“@type”: “Question”,”name”: “What Precautions Should Be Taken When Working With The Electrical Systems Of A Metal Lathe To Prevent Accidents?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with a metal lathe, always wear safety goggles to protect your eyes. Keep your hands dry, and don’t touch wires with wet hands. Make sure the machine is off before you work on it. You should also unplug it to avoid any accidents. Finally, be careful around moving parts and never reach into the machine while it’s running.”}}]}