Have you ever wondered how metal objects are made with precise detail? A lathe is a tool that helps create these accurate shapes. Imagine turning a simple block of metal into a beautiful piece with just a few steps. This magic happens during a lathe training course!

Many people start their journey with a mini metal lathe. It’s small and perfect for beginners. But what can you really learn from this kind of training? You can master basics like cutting, shaping, and sanding metal.

Here’s a fun fact: A lathe has been used for thousands of years! Ancient craftsmen relied on it for their creative projects. Today, learning these skills can open many doors for you. Whether for hobbies or a new career, a lathe training course might just be the adventure you need.

So, are you ready to dive into the world of metalworking? Join a lathe training course and explore the creative possibilities!

Comprehensive Lathe Training Course For Mini Metal Lathe

A lathe training course for a mini metal lathe teaches hands-on skills for beginners. Participants learn about the machine’s operation and safety tips. Did you know that mini lathes can create precision parts for hobbies, like model building? This course covers essential techniques, such as turning, facing, and drilling. By the end, you’ll feel confident using a lathe for personal projects, sparking creativity and practical thinking. Who knew learning about machines could be so fun?

Understanding Mini Metal Lathes

Definition and features of mini metal lathes. Advantages of using a mini metal lathe in machining.

Mini metal lathes are small machines used to shape metal. They can spin metal pieces very fast. This helps create different shapes like cylinders or cones. Key features include adjustable speeds and easy-to-use controls. With a mini lathe, you can enjoy advantages such as:

- Space-saving design

- Simple setup

- Lower cost compared to larger lathes

- Ideal for beginners

They make it easy for hobbyists and learners to practice machining skills.

What are the benefits of using a mini metal lathe?

Benefits include affordable pricing and versatility for small projects. Mini lathes are great for learning and can handle various materials.

Benefits of Lathe Training Courses

Skills development and practical applications. Safety protocols and best practices in lathe operation.

Taking a lathe training course is like upgrading from a tricycle to a sports car! First off, you gain practical skills. You’ll learn how to create amazing metal shapes that will impress your friends (and maybe food critics, if you can make a spoon!).

Safety is a big part too. Know the dos and don’ts. For example, never wear loose clothing around a lathe, unless you want to test how fast it can pull you in!

| Skills Developed | Best Practices |

|---|---|

| Metal shaping | Wear safety goggles |

| Tuning lathe settings | No distractions! |

Embrace the adventure of lathe training. You’ll become a whiz at handling tools and safety—all while having fun!

What to Look for in a Lathe Training Course

Course curriculum and handson experience. Instructor qualifications and teaching methods.

Picking the right lathe training course can make a difference. Look at the course curriculum. It should offer hands-on experience with the mini metal lathe. This helps you practice what you learn. Also, check the instructor’s background. Are they qualified? A good teacher makes learning easier. They should use clear methods to explain. This ensures you really grasp the skills.

What should the course curriculum include?

Look for topics that build your skills. Here are some important elements:

- Basic lathe operations

- Safety practices

- Tool use and care

- Project-based learning

Why are instructor qualifications important?

A qualified instructor can help you learn better. They might have real-world experience or certifications. This expertise allows them to teach effectively and answer your questions.

Online vs. In-Person Training Options

Pros and cons of online training programs. Benefits of handson learning in workshops.

Choosing between online and in-person training can feel like picking your favorite pizza topping. Both options come with fun and some not-so-fun parts. Online courses are great for learning at your own pace, but they lack hands-on experience. This means you might miss the joy of making metal shavings fly! In-person workshops let you dive into the action, feeling the machines and gaining skills right away. Here’s a quick look at their pros and cons:

| Training Type | Pros | Cons |

|---|---|---|

| Online | Flexible schedule No location limits |

Less hands-on experience Can feel lonely |

| In-Person | Hands-on learning Instant feedback |

Fixed schedule Travel needed |

In the end, choose what works best for you! Enjoy spinning some metal and have fun in whichever class you decide!

Preparing for Your Lathe Training Course

Necessary tools and materials to bring. Precourse requirements and prerequisites.

Before your lathe training course, gather essential tools and materials. You might need safety goggles, gloves, and a notebook for notes. Pre-course requirements often include basic knowledge of machining. Check if you need prior experience; some courses are gentle like a summer breeze.

Let’s keep it light and fun! Remember, forgetting your tools can feel like going to a pizza place without your appetite!

| Items to Bring | Precourse Requirements |

|---|---|

| Safety Goggles | Basic Machining Knowledge |

| Gloves | Prior Experience (Check Course Details) |

| Notebook | Excitement and Curiosity! |

Being prepared makes for a smooth start. Happy training, and don’t forget your sense of humor along with those tools!

Success Stories from Lathe Course Graduates

Testimonials and case studies. Career advancements posttraining.

Many graduates from the lathe training course have fantastic stories to share. They transformed their skills and boosted their careers! One learner, Alex, landed a job at a manufacturing plant, making parts that keep machines running smoothly. Another, Jamie, opened a small business creating custom metal art. Isn’t that cool? Here’s a peek at their success:

| Name | Achievement |

|---|---|

| Alex | Job at a manufacturing plant |

| Jamie | Custom metal art business |

These stories show that with hard work and training, you can achieve amazing things. Who knows, maybe you’ll be the next big success!

Continuing Education and Advanced Training Opportunities

Options for specialized training beyond basic courses. Importance of lifelong learning in machining.

There are many paths to grow your skills beyond basic lathe training courses. Specialized workshops teach advanced techniques that can kick your machining game up a notch. Lifelong learning is like adding frosting to your cake; it makes everything better! Staying updated helps keep your skills sharp and your mind engaged. Plus, you never know when new tricks will come in handy—especially when your buddy asks for help on a project!

| Training Option | Focus Area |

|---|---|

| Advanced Machining Techniques | Complex projects and precision work |

| CNC Programming | Automation and advanced machinery |

| Tool Design | Creating custom tools for unique tasks |

Remember, learning is a journey, not a race. Enjoy each new class like it’s your favorite snack, and watch your skills soar!

Frequently Asked Questions About Lathe Training

Common queries related to course selection. Clarifications on certifications and industry recognition.

Many people have questions before joining a lathe training course. First, they wonder how to pick the right course. Look for classes that match your skill level and interests. It’s like finding the perfect ice cream flavor—everyone has their favorite! Next, let’s talk about certificates. Do they help? The answer is yes! A good certificate boosts your chances of landing a job. So remember, choose wisely and always verify if the course is industry-recognized.

| Question | Answer |

|---|---|

| How do I choose a course? | Look for one that matches your skills and interests. |

| Do I need a certificate? | Yes, it often helps in job hunting! |

Conclusion

In conclusion, a lathe training course with a mini metal lathe teaches you essential skills for metalworking. You gain hands-on experience and learn to create precise parts. This training can open doors to new projects and careers. We encourage you to explore local courses or online resources to start your journey into machining today!

FAQs

What Are The Essential Safety Precautions To Follow When Operating A Mini Metal Lathe During Training?

When using a mini metal lathe, always wear safety goggles to protect your eyes. Keep hands away from moving parts. Tie back long hair and avoid loose clothing that could get caught. Make sure to keep your workspace clean and organized. Finally, listen carefully to your instructor and ask questions if you’re unsure about something.

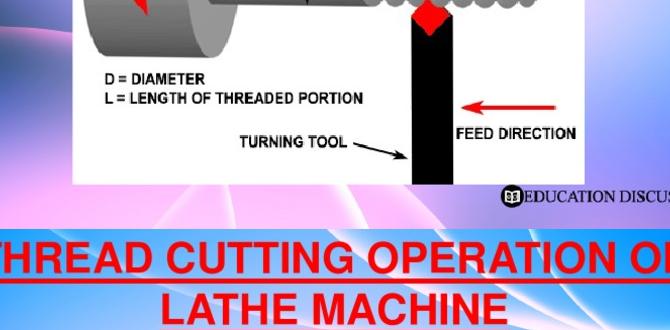

What Are The Key Components Of A Mini Metal Lathe That Trainees Should Understand Before Starting Their Practical Work?

Before you start working with a mini metal lathe, you should know a few main parts. The **bed** holds everything steady. The **headstock** holds the motor and spinning parts. The **tailstock** helps support the metal you’re cutting. Finally, the **tool rest** is where you place the cutting tools. Understanding these parts helps keep you safe and makes your work easier!

How Can Learners Effectively Set Up A Mini Metal Lathe For Various Types Of Machining Tasks?

To set up a mini metal lathe, start by choosing the right tools. Make sure you have the right cutting tools for the job. Next, adjust the speed of the lathe for the material you are working with. You can clamp your metal in place securely. Finally, always wear safety gear like goggles and gloves while you work!

What Types Of Projects Or Exercises Are Typically Included In A Mini Metal Lathe Training Course To Enhance Hands-On Skills?

In a mini metal lathe training course, you might work on simple projects like making small parts. We could create a pencil holder or a toy car. You can practice cutting, shaping, and polishing metal pieces. These fun exercises help you learn how to use the lathe safely and correctly. You’ll get better with each project you complete!

How Does A Mini Metal Lathe Differ From Larger Lathes In Terms Of Functionality And Applications In Metalworking?

A mini metal lathe is smaller than larger lathes. It’s easier to use for small tasks. You can make little parts like screws and gears. Larger lathes can handle bigger pieces and more complex jobs. So, we use mini lathes for simple projects and larger ones for heavy work.