Have you ever thought about how furniture legs are made? They might seem simple, but crafting them can be an art. Lathe turning for furniture legs is a special technique used by skilled craftsmen. This method shapes wood into beautiful and functional pieces.

Imagine walking into a cozy home. The furniture catches your eye, especially the stylish legs of the coffee table. Those legs did not just happen by accident. They were carefully turned on a lathe, creating curves and designs that wow everyone.

Lathe turning is not just for experts. Many DIY enthusiasts enjoy trying it out too. With the right tools and a little practice, anyone can create unique furniture legs. Wouldn’t it be fun to design your own? You can build pieces that impress your friends and family.

In this article, we will explore how lathe turning works. We’ll also share tips on getting started. Get ready to discover the magic behind crafting stunning furniture legs!

Lathe Turning For Furniture Legs: Create Unique Designs

Lathe Turning for Furniture Legs

Lathe turning is a fascinating craft used to create beautiful furniture legs. By shaping wood on a lathe, you can make unique designs that fit your style. Did you know that a well-crafted wooden leg can transform a simple table into a masterpiece? Whether it’s a modern look or a vintage vibe, lathe turning offers endless possibilities. Mastering this skill can lead to impressive projects that impress family and friends. Why not give it a try?Understanding Lathe Turning Basics

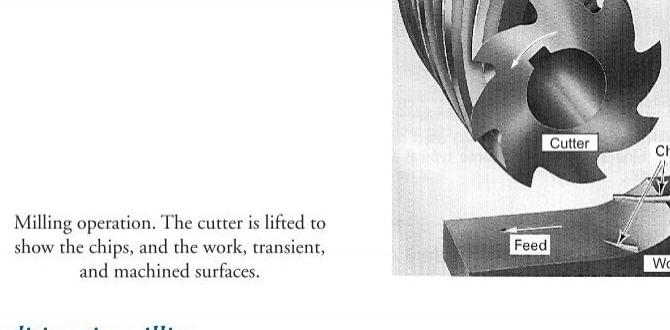

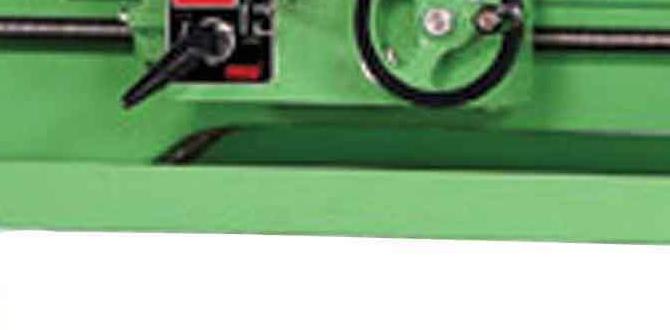

Definition of lathe turning and its significance in furniture making. Types of lathes used for turning furniture legs.Lathe turning is like giving furniture legs a stylish haircut! It shapes wood into smooth, curved designs that make chairs and tables special. This process is super important in furniture making because it adds flair and precision. There are different types of lathes, each with unique skills. For example, a *wood lathe* works wonders on softer woods. Here’s a quick look at some lathes:

| Type of Lathe | Best For |

|---|---|

| Wood Lathe | Softwoods and detailed designs |

| Metal Lathe | Harder materials |

| Mini Lathe | Small projects |

So, whether you’re crafting a sleek leg for a coffee table or a funky one for a stool, lathe turning makes it happen with style!

Tools and Materials Needed for Lathe Turning

Essential tools for lathe turning (chisels, gouges, etc.). Recommended types of wood for furniture legs.Lathe turning requires some important tools and materials. You’ll need sharp chisels and gouges to shape the wood. These tools help create smooth curves and edges. Good options for wood are maple, oak, and walnut. These woods are strong and look great for furniture legs. Make sure to choose the right tools and wood to get started on creating your furniture pieces!

What tools do you need for lathe turning?

For lathe turning, you will need:

- Chisels: For different shapes.

- Gouges: For curved edges.

- Sandpaper: To smooth the surface.

- Faceplate: To hold the wood steady.

- Safety gear: Like goggles to protect your eyes.

Which wood is best for furniture legs?

The best woods for furniture legs include:

- Maple: Durable and nice grain.

- Oak: Strong with a beautiful finish.

- Walnut: Rich color and easy to work with.

Safety Precautions in Lathe Turning

Personal protective equipment (PPE) required. Safe operating practices to avoid accidents.Using a lathe can be fun, but safety is super important. Always wear personal protective equipment (PPE) to keep yourself safe. That includes:

- Safety goggles to protect your eyes.

- Ear protection to guard against loud noises.

- Gloves to avoid cuts and scrapes.

Follow these safe practices to prevent accidents:

- Keep your workspace clean.

- Never wear loose clothing.

- Always check the machine before use.

Following these tips keeps you safe while you enjoy turning furniture legs on the lathe!

What is PPE in lathe turning?

PPE in lathe turning refers to items like goggles, ear protection, and gloves that help protect you while using the machine.

Step-by-Step Guide to Turning Furniture Legs

Preparing the wood and setting up the lathe. Detailed turning techniques for creating various leg shapes.First, choose the right wood for the legs. Softwoods, like pine or poplar, are easy to work with. Next, cut it into smaller pieces. This makes it easier to handle. Now, set up your lathe. Make sure it’s on a stable surface and the tools are sharp.

Let’s get turning! For simple shapes, keep the tool steady and follow the wood’s curve. Use different chisels to create patterns. Try a tapered leg for a trendy look or a turned leg for fancy designs. Remember, if your leg looks more like a pretzel than a pillar, you might want to try again!

| Shape | Technique |

|---|---|

| Tapered | Keep the tool angled |

| Turned | Use multiple chisels |

With practice, you’ll be a pro in no time. Happy turning, and may your legs be strong and straight!

Designing Attractive Furniture Legs

Popular leg styles and their aesthetics. Incorporating custom designs and details in leg turning.Furniture legs can really make or break a piece! Popular styles include tapered, turned, and splayed. Each style creates a different look. Tapered legs are sleek and modern, while turned legs feel classic and elegant. Got a wild idea? Custom designs can add fun twists, like adding spirals or even little faces! Here’s a quick peek into some leg styles:

| Style | Aesthetics |

|---|---|

| Tapered | Modern and chic |

| Turned | Classic and detailed |

| Splayed | Bold and playful |

Remember, the right legs can bring your furniture to life! So, be creative and let your imagination roam freely, like a cat in a yarn store!

Finishing Techniques for Furniture Legs

Surface preparation before finishing. Best finishing products (stains, paints, varnishes) and application methods.Before applying any finish to furniture legs, you need to prepare the surface. This means sanding the wood to make it smooth. Clean off any dust and dirt afterward. Use high-quality finishing products for the best results. Here are some options:

- Stains: They add color while showing wood grain.

- Paints: They provide solid color and can hide flaws.

- Varnishes: They protect the wood and add shine.

Application methods vary. You can use a brush, rag, or spray. Follow the product instructions for good results. Choosing the right finish will make your furniture legs look great!

What is the best way to finish furniture legs?

The best way is to prepare the surface first. Then, choose the right stain, paint, or varnish. Apply it evenly for a nice look!

Common Mistakes to Avoid in Lathe Turning

Typical errors beginners make and how to prevent them. Troubleshooting tips for common lathe turning issues.Many beginners make mistakes while lathe turning. These errors can lead to wasted materials and frustration. To help, here are some tips to avoid common errors:

- Incorrect speed setting can ruin projects. Always match the speed to the material you’re using.

- Poor tool alignment can cause uneven cuts. Regularly check your tool’s position.

- Not wearing safety gear is dangerous. Always use goggles and ear protection.

If problems arise, troubleshoot quickly. Check for control issues, tool dullness, or material problems. By staying alert and ask for help when needed, you can improve your skills and create beautiful furniture legs.

What are some common mistakes in lathe turning?

Common mistakes include mispositioning tools, using wrong speeds, and ignoring safety rules.

Maintenance and Care of Your Lathe

Regular maintenance routines to ensure longevity of the lathe. How to troubleshoot common lathe problems.To keep your lathe in great shape, regular check-ups are key. Clean and oil your lathe frequently. This helps parts move smoothly. Always check for worn parts too. If something seems off, try these simple troubleshooting tips:

- Listen for strange noises.

- Feel for vibrations or wobbling.

- Check the belt for damage.

Remember, a well-maintained lathe makes smoother furniture legs!

What are common lathe problems?

Common issues include rough cuts, excess vibration, and bad alignment. Keeping your lathe clean helps avoid these problems.

Resources for Further Learning

Books and online courses for advanced lathe turning skills. Recommended forums and communities for woodturning enthusiasts.If you’re eager to level up your lathe turning skills, there are fantastic resources available. Begin with some great books like “Turning Pens and Pencils” or “Woodturning for the Absolute Beginner.” Online courses are also super helpful. You can check out sites like Skillshare or Udemy for classes that fit your level. Don’t forget the online communities where woodturning fans hang out! They share tips, tricks, and stories that can make you chuckle.

| Resource Type | Recommendations |

|---|---|

| Books | “Turning Pens and Pencils”, “Woodturning for the Absolute Beginner” |

| Online Courses | Skillshare, Udemy |

| Forums/Communities | Woodturner’s Guild, Reddit’s Woodworking Forum |

Engaging with these resources can turn your lathe turning journey into a fun adventure. Plus, who knows? You might come across a fellow woodturner who can help you find the perfect leg for your next furniture masterpiece!

Conclusion

In conclusion, lathe turning is a fun way to create sturdy furniture legs. You can shape wood into beautiful designs with this technique. Remember to take safety precautions and practice your skills. If you’re interested, explore tutorials or books on lathe turning. You’ll discover new ideas and improve your woodworking projects. Start creating your furniture legs today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning For Furniture Legs:Lathe turning is a way to shape wood. You put a piece of wood on a machine called a lathe. As the wood spins, you use tools to carve it into a nice shape. This method helps us create smooth and pretty furniture legs. It takes practice, but you can make wonderful things with a lathe!

Sure! Please provide me with the question you’d like me to answer.

What Are The Essential Tools And Materials Required For Turning Furniture Legs On A Lathe?To turn furniture legs on a lathe, you need a few important tools. First, you need a lathe, which spins the wood. Then, you will need chisels to shape the wood. Sandpaper helps smooth the surface. Finally, wood and a measuring tape will help you know the right size.

How Do You Determine The Correct Dimensions And Proportions For Furniture Legs Before Starting The Lathe Turning Process?To find the right size for furniture legs, you first think about what the table or chair needs. You can measure the height from the ground to where you want the seat or tabletop. Next, we sketch a rough idea of how thick and tall we want the legs to be. It helps to look at other furniture for inspiration. Finally, we can use those measurements to plan before starting to work on the lathe.

What Safety Precautions Should Be Taken When Operating A Lathe For Turning Furniture Legs?When you use a lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Make sure the area is clean and free of clutter. Always use both hands on the wood and never reach near moving parts. If you’re unsure, ask an adult for help.

How Can You Achieve Different Designs And Styles Of Furniture Legs Through Lathe Turning Techniques?You can create different designs for furniture legs by using a lathe. A lathe is a tool that spins wood while you shape it. You can make legs round, square, or fancy by changing how you cut. You just need to practice and try different cuts to see what you like best!

What Are Some Common Mistakes To Avoid When Turning Furniture Legs On A Lathe, And How Can They Be Corrected?When turning furniture legs on a lathe, don’t forget to measure twice and cut once. If you cut too much, you might ruin the leg. To fix this, always check your measurements carefully before starting. Also, make sure the wood is secured tightly. If it wobbles, it can make a messy shape. If it starts to wobble, turn off the lathe and tighten the wood again.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Turning For Furniture Legs:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe turning is a way to shape wood. You put a piece of wood on a machine called a lathe. As the wood spins, you use tools to carve it into a nice shape. This method helps us create smooth and pretty furniture legs. It takes practice, but you can make wonderful things with a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Materials Required For Turning Furniture Legs On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To turn furniture legs on a lathe, you need a few important tools. First, you need a lathe, which spins the wood. Then, you will need chisels to shape the wood. Sandpaper helps smooth the surface. Finally, wood and a measuring tape will help you know the right size.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Dimensions And Proportions For Furniture Legs Before Starting The Lathe Turning Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size for furniture legs, you first think about what the table or chair needs. You can measure the height from the ground to where you want the seat or tabletop. Next, we sketch a rough idea of how thick and tall we want the legs to be. It helps to look at other furniture for inspiration. Finally, we can use those measurements to plan before starting to work on the lathe.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Lathe For Turning Furniture Legs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Make sure the area is clean and free of clutter. Always use both hands on the wood and never reach near moving parts. If you’re unsure, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Can You Achieve Different Designs And Styles Of Furniture Legs Through Lathe Turning Techniques?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can create different designs for furniture legs by using a lathe. A lathe is a tool that spins wood while you shape it. You can make legs round, square, or fancy by changing how you cut. You just need to practice and try different cuts to see what you like best!”}},{“@type”: “Question”,”name”: “What Are Some Common Mistakes To Avoid When Turning Furniture Legs On A Lathe, And How Can They Be Corrected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When turning furniture legs on a lathe, don’t forget to measure twice and cut once. If you cut too much, you might ruin the leg. To fix this, always check your measurements carefully before starting. Also, make sure the wood is secured tightly. If it wobbles, it can make a messy shape. If it starts to wobble, turn off the lathe and tighten the wood again.”}}]}