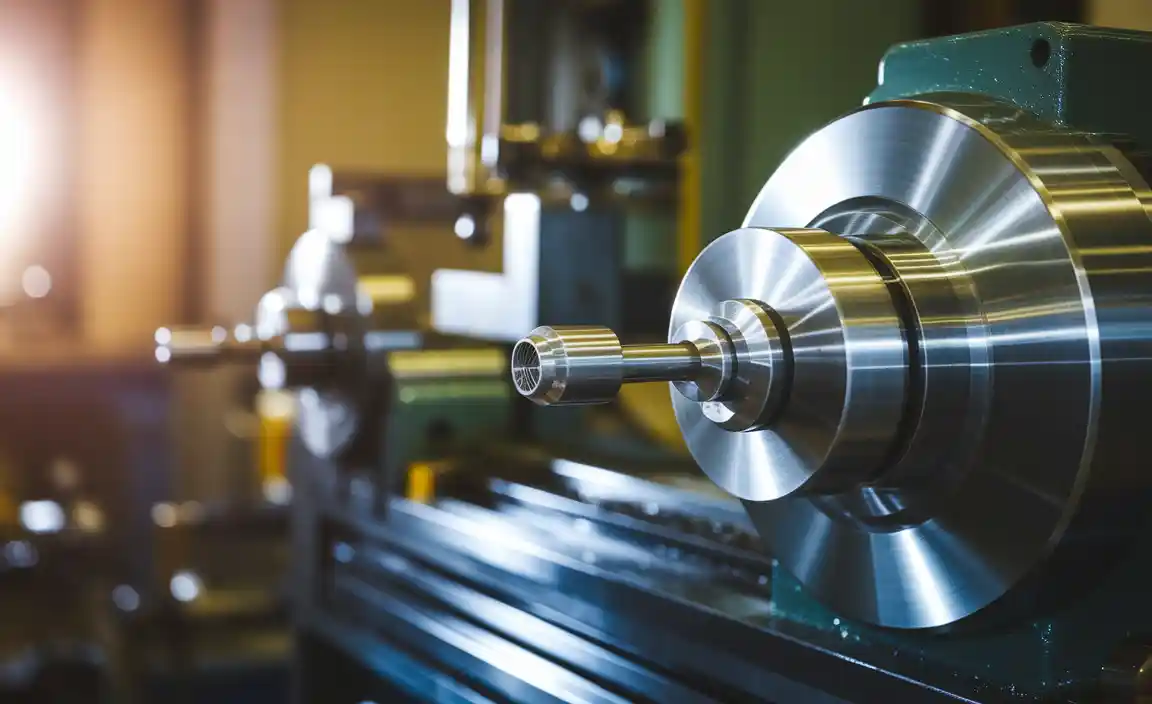

Have you ever watched a lathe spinning wood or metal? It’s fascinating! But did you know that even small mistakes can lead to big problems? That’s where lathe turning offset spindle center techniques come into play.

These techniques help ensure that your materials stay centered while turning. Imagine trying to make a smooth, round shape, only to find it wobbles! It can be frustrating. However, learning how to adjust the spindle center makes all the difference.

Let’s think about it. What if you had a magic tool that made perfect shapes every time? That’s what mastering these techniques feels like. In this article, we’ll dive into tips and tricks that can help you become a lathe turning expert.

Get ready to explore the world of lathe turning. You’ll be amazed at how much simpler it can be with the right knowledge!

Lathe Turning Offset Spindle Center Techniques Explained

Understanding Offset Spindle Centers

Definition and purpose of offset spindle centers in lathe turning.. Importance of accuracy and alignment in machining processes..

Offset spindle centers are special setups in lathe turning. They allow the machine to work on parts that aren’t perfectly centered. This is important because it helps create precise shapes. Accuracy and alignment are key in machining. If things aren’t lined up right, the results can be off. This can mess up projects and waste materials. To keep everything running smoothly, remember these points:

- Define offset spindle centers clearly.

- Ensure high accuracy in positioning.

- Check alignment frequently.

Why is accuracy important in machining?

Accuracy ensures quality products and saves time. Precision makes sure parts fit well together and work as intended.

What happens without alignment?

Without proper alignment, tools may cut unevenly. This results in wasted materials and extra work.

Tools and Equipment Needed

List of essential tools required for effective offset turning.. Discussion on different types of lathes compatible with offset techniques..

To master offset turning, gather essential tools. You’ll need a lathe, cutting tools, and a dial gauge. A reliable workbench helps too. Here’s a simple list:

- Lathe: Choose one with adjustable spindle.

- Cutting tools: High-speed steel works well.

- Dial gauge: This helps measure offsets.

- Calipers: Accurate measurements matter.

Different lathes suit offset techniques. Some are manual, while others are CNC. Manual lathes offer hands-on control. CNC lathes provide precision. Find what fits your project best!

What tools do you need for offset turning?

You need a lathe, cutting tools, a dial gauge, and calipers for offset turning.

By using the right tools, you can create amazing shapes. Each tool plays a crucial role in achieving desired results. Starting with the basics makes offset turning fun and creative!

Step-by-Step Guide to Implementing Offset Spindle Center

Detailed procedures to set up a lathe for offset turning.. Tips for maintaining proper alignment and minimizing errors..

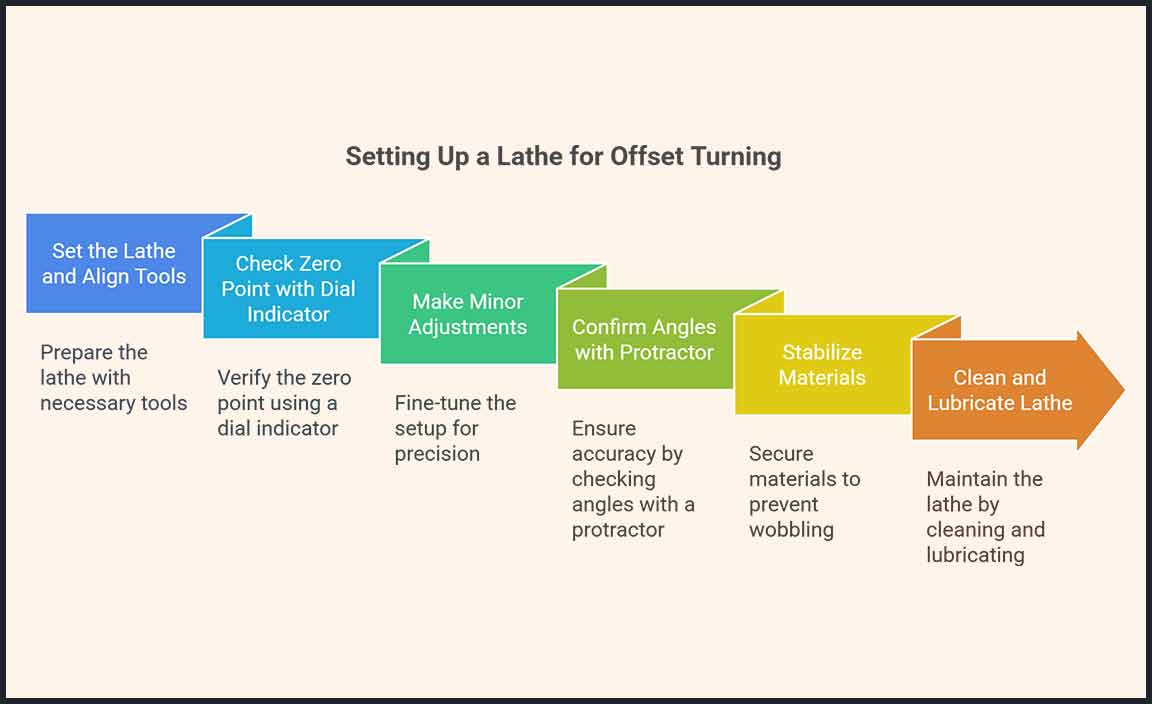

Start by setting your lathe with the right tools. Use a dial indicator to check the zero point. Make tiny adjustments. Remember, a millimeter can make a huge difference! Next, double-check your work with a protractor for extra accuracy. Keep your materials stable to avoid wobbles—they can turn a masterpiece into a pancake. For maintenance, regularly clean and lubricate your lathe. A well-oiled machine is a happy machine; just don’t overdo it—too much grease and it may feel like it’s slipping on banana peels!

| Step | Description |

|---|---|

| 1 | Set the lathe and align tools correctly |

| 2 | Check the zero point with a dial indicator |

| 3 | Make minor adjustments for precision |

| 4 | Use a protractor to confirm angles |

| 5 | Stabilize materials to prevent wobbling |

| 6 | Regularly clean and lubricate your lathe |

These steps should guide you to achieving the perfect offset spindle center. Happy turning!

Common Challenges and Solutions

Identification of frequent problems encountered with offset turning.. Suggested solutions and best practices to overcome these challenges..

Using offset turning can be tricky. Many face common problems, like misalignment or uneven cuts. These issues can lead to wasted materials and time. But, don’t worry! Here are ways to solve them:

- Check alignment regularly to ensure everything is straight.

- Use quality tools to achieve better results.

- Adjust settings slowly until you find the right fit.

By following these tips, you can tackle challenges head-on and enjoy smooth turning!

What are the common problems in lathe turning?

Common problems include misalignment, tool wear, and vibration issues. Understanding these can help you prevent mistakes and save time.

Real-World Applications of Offset Spindle Center Techniques

Examples of industries and projects that benefit from offset turning.. Insights into how these techniques enhance productivity and precision..

Many industries rely on offset spindle techniques to boost productivity. For instance, the automotive sector uses these methods for creating precise engine components. Aerospace companies appreciate how they enhance aircraft part accuracy. Even small machine shops benefit by saving time and reducing waste.

These techniques improve efficiency, allowing workers to produce more items faster without sacrificing quality. In fact, studies show that offset turning can increase output by up to 30%. It’s like cooking an entire banquet without burning the turkey!

| Industry | Benefit | Example |

|---|---|---|

| Automotive | Increased Precision | Engine Components |

| Aerospace | Higher Accuracy | Aircraft Parts |

| Small Shops | Time Savings | Custom Parts |

Expert Tips for Advanced Users

Pro tips and tricks for refining offset turning skills.. Recommendations for further training and skill development..

Mastering offset turning can be exciting! Here are some expert tips to enhance your skills:

- Practice regularly to build confidence and precision.

- Explore various projects to broaden your experience.

- Ask for feedback from more experienced users to improve.

For continued growth, consider these options:

- Join local workshops to learn hands-on techniques.

- Watch online tutorials for different perspectives.

- Read books on advanced lathe techniques.

These strategies will help you refine your skills and become a lathe turning expert!

What are the best ways to improve lathe turning skills?

The best ways to improve are by practicing regularly, seeking advice from experts, and trying out different projects. Workshops and online resources can also boost your skills.

Conclusion

In summary, lathe turning offset spindle center techniques help you create more precise and intricate designs. By adjusting the spindle position, you can achieve unique shapes and patterns. We encourage you to practice these techniques and explore different projects. Remember, hands-on experience is the best way to learn. Keep reading and practicing to master your lathe skills!

FAQs

What Are The Common Methods For Determining Spindle Center Offset In Lathe Turning Operations?

To find the spindle center offset in lathe turning, you can use a few simple methods. One way is to use a dial indicator. This tool measures how far the spindle is from the center. You can also use a piece of calibration material, like a straight rod. By checking the distance from the rod to the spindle, you can see if it’s off.

How Does Misalignment Of The Spindle Center Affect The Accuracy And Quality Of The Finished Workpiece?

When the spindle is not in the right place, it can cause problems for the piece we are working on. You might end up with uneven cuts or shapes that aren’t quite right. This means the finished workpiece can look messy or not fit together well. In short, keeping the spindle center aligned helps make sure our work turns out neat and correct.

What Techniques Can Be Employed To Correct Or Compensate For Spindle Center Offset During Lathe Setup?

To fix the spindle center offset on a lathe, we can use a few simple tricks. First, we can adjust the position of the tool holder to change its height. Next, we can use shims, which are thin pieces of material, to lift or lower the tool. Lastly, we can check and align the lathe’s tailstock if needed. These steps help the tool cut in the right spot!

How Do Different Types Of Lathes (E.G., Cnc Vs. Manual) Handle Spindle Center Offset Adjustments?

CNC lathes can automatically change the spindle center. You just have to set it up in the computer. Manual lathes need you to adjust it by hand. In a manual lathe, you turn knobs or screws to make changes. Both types help make sure your work is accurate!

What Are The Indicators Or Signs That Suggest A Spindle Center Offset May Be Present During Lathe Machining?

If the spindle center is off, you might notice a few things. First, the part you are making could look uneven or wobbly. You might also see a rough surface instead of a smooth finish. Finally, if you hear strange noises while the lathe is working, that could be a sign too. These clues help us find problems with the spindle position.

Resource:

-

Machinery’s Handbook comprehensive machining guide https://www.industrialpress.com/machinerys-handbook-31st-edition

-

Practical Machinist Forum community advice on machining problems: https://www.practicalmachinist.com

-

MIT OpenCourseWare – Manufacturing Processes foundational manufacturing concepts: https://ocw.mit.edu/courses/mechanical-engineering/2-008-design-and-manufacturing-i-spring-2006/

-

American Woodturner Magazine expert tips on wood lathe techniques: https://www.woodturner.org/page/AWMag