Have you ever wondered how those beautiful pens are made? A simple piece of wood can turn into a stunning pen with the right tools. When it comes to crafting pens, lathe turning is a popular method. But there’s more to it than just spinning wood. Drilling accuracy is key!

Imagine holding a pen that feels just right in your hand. It’s not just about looks; it has to work well too. If the holes aren’t drilled precisely, the pen won’t be balanced. This could ruin the whole project! So, how do skilled artisans achieve that perfect balance during lathe turning?

In this article, we’ll explore the world of lathe turning pen blank drilling accuracy. You’ll discover tips and tricks to improve your own pen-making skills. Get ready to dive into the fun and exciting methods that can make your pen stand out!

Lathe Turning Pen Blank Drilling Accuracy For Precision Crafting

Lathe Turning Pen Blank Drilling Accuracy

Lathe turning pen blank drilling accuracy is crucial for making beautiful pens. When drilling, precision helps ensure a perfect fit for tubes. A straight hole keeps everything aligned, leading to a smooth finish. Did you know that even a tiny mistake can change the pen’s look? Using jigs can improve your drilling and boost your confidence. So, why not try these tips on your next project? Your pens could turn out even better!Choosing the Right Equipment for Lathe Turning

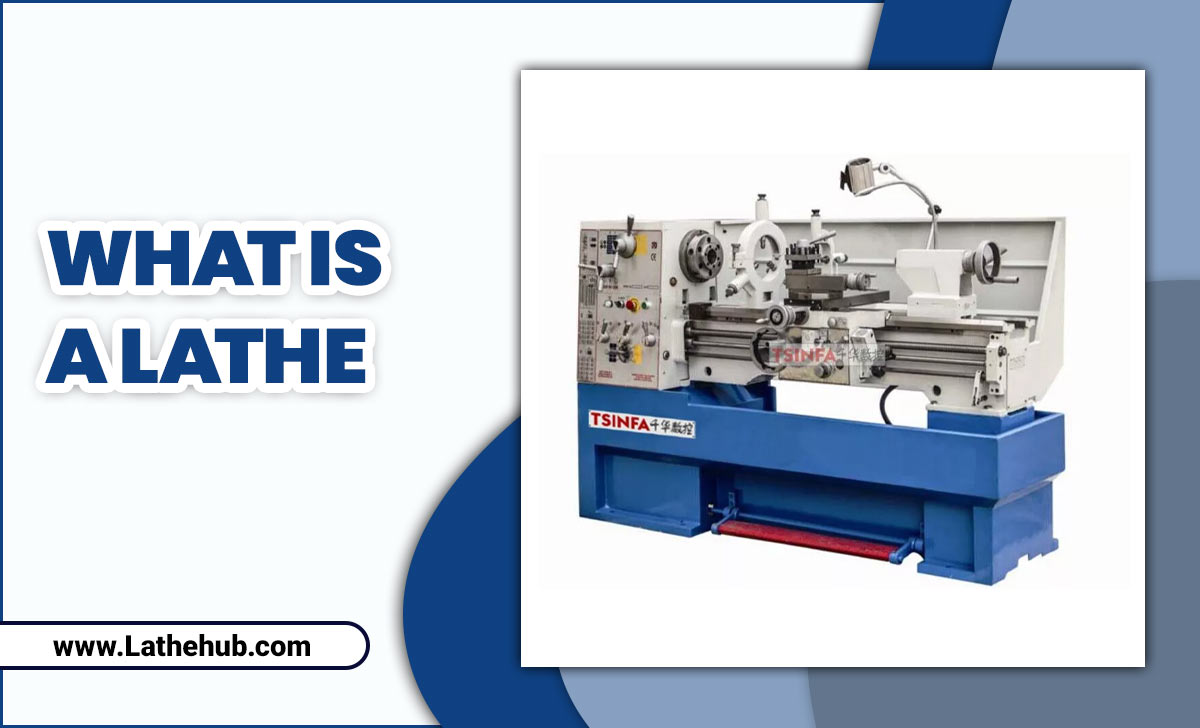

Essential tools and their roles in achieving precision.. Recommended lathe models for beginners and experts alike..Choosing the right tools can make all the difference in lathe turning. Essential tools include a high-quality lathe, sharp chisels, and measuring devices. Each tool plays a key role in ensuring lathe turning pen blank drilling accuracy.

For beginners, consider models like the Jet JWL-1015 or the Rikon 70-100. Experts might prefer the Powermatic 3520C for its precision. Invest in good equipment and watch your skills grow!

What tools do I need for lathe turning?

You will need several tools for lathe turning. The most important are your lathe, chisels, and measuring tools. A lathe helps shape the wood, while chisels refine details. Measuring tools ensure everything is accurate.

Essential Tools for Lathe Turning:

- Lathe

- Chisels

- Measuring calipers

- Wood blanks

Preparing the Pen Blank for Drilling

Stepbystep process of selecting and cutting pen blanks.. Importance of grain orientation and how it affects drilling accuracy..Choosing and preparing your pen blank is vital for a great pen. First, pick good wood with nice patterns. Next, cut it neatly to the right size. Measure twice, cut once! Grain orientation matters a lot. If the grain runs the right way, it helps your drill make a clean hole. This ensures better drilling accuracy. Remember, a smooth hole leads to a finer pen. Take your time to get it right!

Why is grain orientation important?

Grain orientation affects the strength and look of your finished pen. If the drill hits the grain correctly, it stays stable. Otherwise, it might split. Choosing this wisely will lead to better results every time!

Steps to Prepare Your Pen Blank:

- Pick quality wood.

- Measure your blanks carefully.

- Cut to the right size.

- Check the grain direction.

Techniques for Drilling Accuracy

Best practices for aligning blanks on the lathe.. Methods to ensure even and precise drilling depth..To achieve precision in your lathe drilling, careful alignment is key. First, secure your blank tightly in the chuck. This helps it stay steady. Using a center drill marks the exact spot for your hole. This prevents wandering during drilling. Here are some best practices:

- Check the blank for any defects.

- Use a digital caliper for measuring depth.

- Drill slowly for better control.

Following these steps ensures even drilling and improves accuracy. Keep practicing to master your skills!

How can I align my blanks accurately?

You can align your blanks by using a center drill to find the exact midpoint. This helps in avoiding mistakes while drilling.

What methods can ensure even drilling depth?

To ensure even depth, mark your drill bit with tape. This gives you a visual cue and keeps your drill from going too deep.

Common Mistakes in Lathe Turning and How to Avoid Them

Frequent errors made by beginners and their implications.. Tips for troubleshooting and correcting drilling inaccuracies..Many beginners make common mistakes in lathe turning. These can lead to uneven cuts or poor drilling accuracy. For instance, not securing the pen blank properly can cause it to wobble. This affects the final product. To avoid these mistakes, remember to check your setup before starting. Here are some tips:

- Use sharp tools to ensure clean cuts.

- Double-check your measurements.

- Secure your workpiece tightly to prevent movement.

Taking time to set up correctly can save you from many headaches later on!

What are the common mistakes in lathe turning?

Common mistakes include: improper tool use, inaccurate measurements, and incorrect speeds. These can lead to wasted materials and time.

How to fix drilling inaccuracies?

- Adjust the speed to match the material.

- Re-align the drill bit if it starts to wander.

- Check for wear and tear on tools regularly.

Advanced Techniques for Proficient Woodturning

Exploring different turning styles and their impacts on accuracy.. How to customize lathe setups for specific pen types..Woodturning can be a fun adventure! Different turning styles can change how precise your work is. If you’re making a fancy pen, try a skew chisel for smooth finishes. Each style has its quirks, much like choosing between cookies or brownies! To nail that perfect pen, customize your lathe setup. Adjust speeds, tools, and even the height can make a difference. Don’t forget to check your drill alignment; it’s key for accuracy!

| Turning Style | Impact on Accuracy |

|---|---|

| Basic | Good for beginners, but may lack finesse. |

| Curved | Offers unique shapes but can be tricky. |

| Skew | Great for precision; think of it as a woodturner’s secret weapon! |

Tools and Resources for Ongoing Improvement

Recommended books, courses, and online resources for skill enhancement.. Community forums and groups to connect with fellow woodturners..Improving your lathe turning skills can be a fun adventure! Start with some great books and online courses that focus on woodturning techniques. You might find yourself chuckling at some hilarious project fails along the way. Online resources like YouTube channels can give you tips that are easier to follow than IKEA instructions.

Don’t forget about joining community forums and groups. Connecting with fellow woodturners will give you support and inspiration. Sharing stories can lead to some laugh-out-loud moments while learning together.

| Recommended Resources | Type |

|---|---|

| Woodturning for Beginners | Book |

| Mastering Woodturning | Online Course |

| The Woodturning Community Forum | Online Forum |

Keep learning, stay connected, and always remember: even the best woodturners started as beginners with a bit of sawdust on their shirts!

Conclusion

In summary, achieving lathe turning pen blank drilling accuracy is vital for creating perfect pens. You need proper tools and techniques to ensure precise holes. Pay attention to measurements and go slow. Practice will improve your skills. We encourage you to explore more resources and try your hand at making a pen. Enjoy the process and have fun!FAQs

What Are The Best Practices For Ensuring The Accuracy Of Drilling Pen Blanks On A Lathe?To make sure your pen blanks are drilled accurately, start by measuring them carefully. Mark the center clearly before drilling. Use a drill press instead of a hand drill for more control. Make sure your pen blank is tight and steady in the machine. Finally, check your work often to fix any mistakes.

How Does The Choice Of Drill Bit Affect The Precision Of Holes Drilled In Pen Blanks?The drill bit you choose can really change how well your holes turn out. A sharp, straight bit makes cleaner holes. If you use a dull or wrong size bit, the holes can be uneven or too wide. This can make it hard to fit parts of the pen together. Always pick the right bit for the best results!

What Measurements Should Be Taken Before Drilling To Achieve Optimal Accuracy In Pen Blank Turning?Before you drill the pen blank, measure its length and diameter carefully. Make sure the center is marked. Use a ruler for straight lines. Check that your drill bit matches the size needed. This way, you’ll drill perfectly!

How Can You Minimize Runout When Drilling Pen Blanks On A Lathe?To minimize runout when drilling pen blanks, choose a good drill bit. Make sure the bit is sharp and straight. You can also use a center finder to position the blank accurately. Tighten everything firmly, so nothing wobbles. Finally, take your time and drill slowly for the best results.

What Tools Or Jigs Can Help Improve Drilling Accuracy For Pen Blanks In Lathe Turning?To drill pen blanks accurately, you can use a drill press. This tool holds the drill steady and straight. You can also try a pen blank drilling jig. It helps line up the blank so you drill straight holes. A vise can keep your blank in place while you drill. These tools make sure your pen blanks are just right!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Ensuring The Accuracy Of Drilling Pen Blanks On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your pen blanks are drilled accurately, start by measuring them carefully. Mark the center clearly before drilling. Use a drill press instead of a hand drill for more control. Make sure your pen blank is tight and steady in the machine. Finally, check your work often to fix any mistakes.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Drill Bit Affect The Precision Of Holes Drilled In Pen Blanks? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The drill bit you choose can really change how well your holes turn out. A sharp, straight bit makes cleaner holes. If you use a dull or wrong size bit, the holes can be uneven or too wide. This can make it hard to fit parts of the pen together. Always pick the right bit for the best results!”}},{“@type”: “Question”,”name”: “What Measurements Should Be Taken Before Drilling To Achieve Optimal Accuracy In Pen Blank Turning? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before you drill the pen blank, measure its length and diameter carefully. Make sure the center is marked. Use a ruler for straight lines. Check that your drill bit matches the size needed. This way, you’ll drill perfectly!”}},{“@type”: “Question”,”name”: “How Can You Minimize Runout When Drilling Pen Blanks On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To minimize runout when drilling pen blanks, choose a good drill bit. Make sure the bit is sharp and straight. You can also use a center finder to position the blank accurately. Tighten everything firmly, so nothing wobbles. Finally, take your time and drill slowly for the best results.”}},{“@type”: “Question”,”name”: “What Tools Or Jigs Can Help Improve Drilling Accuracy For Pen Blanks In Lathe Turning? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To drill pen blanks accurately, you can use a drill press. This tool holds the drill steady and straight. You can also try a pen blank drilling jig. It helps line up the blank so you drill straight holes. A vise can keep your blank in place while you drill. These tools make sure your pen blanks are just right!”}}]}