Have you ever watched a lathe in action? It’s amazing how it can transform a simple piece of metal into something beautiful. Lathe turning with round carbide inserts is a popular technique among machinists. But why are these inserts so special?

Imagine holding a tool that can slice through tough materials with ease. Round carbide inserts are designed just for that. They can cut smoothly, making the turning process faster and more efficient. Many machinists choose them for their ability to last longer than regular tools.

One fun fact to consider is that carbide inserts help create precise shapes. This makes them perfect for projects where detail matters. Have you ever needed a specific part that fits just right? Lathe turning with these inserts can make that happen.

As we dive deeper into the world of lathe turning, you’ll discover techniques that can improve your skills. So, get ready to learn why using round carbide inserts might just change the way you create!

Lathe Turning With Round Carbide Inserts: A Comprehensive Guide

Lathe Turning with Round Carbide Inserts

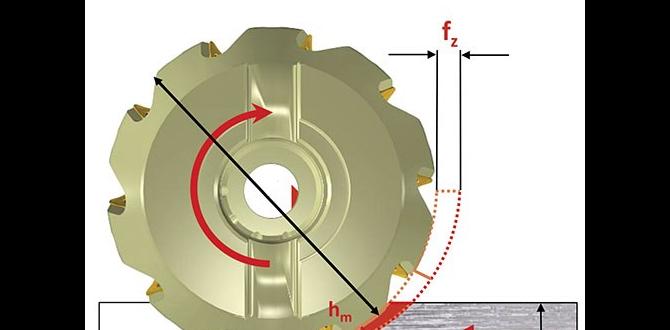

Lathe turning with round carbide inserts offers a smooth and efficient way to shape metal. These inserts last longer than traditional ones, saving both time and money. Imagine crafting precise pieces without frequent tool changes! A fun fact: round inserts can cut in all directions, making them versatile. This method suits various projects, from intricate designs to larger components. With the right approach, you can achieve professional-quality results easily. Why not explore this technique and enhance your skills?What are Round Carbide Inserts?

Definition and composition of round carbide inserts. Benefits of using round carbide inserts in lathe turning.Round carbide inserts are small, sharp tools made of a tough material called carbide. This material is a blend of carbon and tungsten, making it hard and durable. Using round carbide inserts in lathe turning offers great benefits. They maintain sharp edges longer and cut through metals like butter. Plus, they can handle high speeds, which saves time. Imagine your lathe turning like a superhero—fast and strong!

| Benefits of Round Carbide Inserts |

|---|

| Long-lasting edges |

| High-speed capabilities |

| Versatile for different materials |

| Less downtime for changes |

Advantages of Using Round Carbide Inserts in Lathe Turning

Enhanced wear resistance and durability. Improved surface finish and accuracy.Using round carbide inserts in lathe turning offers many benefits. These inserts have enhanced wear resistance, meaning they last longer. This durability saves time and money. They also provide an improved surface finish and better accuracy. Parts made with these inserts are smoother and fit together perfectly.

What are the benefits of round carbide inserts?

Round carbide inserts help tools stay sharp longer and create high-quality pieces in lathe turning.

Advantages of round carbide inserts:

- Last longer due to wear resistance

- Produce smoother surfaces for better fit

- Enhance accuracy in cutting

Choosing the Right Round Carbide Insert for Your Project

Factors to consider: material, cutting speed, and insert geometry. Recommendations based on common applications.Choosing the best round carbide insert can make your project shine! Think about your material first. Is it metal or plastic? Each needs a different insert. Next, look at the cutting speed. Faster usually means hotter, so pick wisely! Finally, geometry matters too. Different shapes cut differently. Here’s a quick guide on common uses:

| Material | Ideal Insert | Cutting Speed |

|---|---|---|

| Steel | PCD Inserts | Medium to High |

| Aluminum | Coated Inserts | High |

| Plastic | Carbide Inserts | Low to Medium |

Remember, a good choice will save time and effort. Choose smartly and let your lathe work wonders! And hey, even the best inserts can’t fix a coffee spill on the project plans!

Setup and Tooling for Lathe Turning with Round Inserts

Proper tool holder setups and alignment techniques. Importance of cutting fluids and lubrication.To achieve great results in lathe turning with round carbide inserts, start with proper tool holder setups. Align your tools carefully. This ensures accuracy and smooth cuts. Also, don’t forget about cutting fluids. They cool the tool and help it last longer. Without lubrication, tools can wear out quickly.

Why is tool alignment important?

Tool alignment is vital for precise cuts and tool longevity. Misalignment can lead to poor finishes and faster wear. Take the time to set up correctly.

Key Tips for Setup and Lubrication:

- Ensure tools sit straight.

- Use appropriate cutting fluids.

- Check for any vibrations.

- Keep the workspace clean.

Best Practices for Lathe Turning with Round Carbide Inserts

Techniques to maximize insert lifespan. Tips for achieving optimal cutting speeds and feeds.To get the most out of your round carbide inserts, try these tips. First, choose the right cutting speed. Too fast can cause wear, while too slow may lead to poor cuts. Aim for a balanced speed! Also, keep it clean. Dirt can hurt your tools. Using the right amount of coolant helps too. It cools the insert and reduces friction.

- Use sharp inserts for cleaner cuts.

- Monitor your feeds and speeds regularly.

- Make small adjustments to optimize performance.

How can we maximize insert lifespan?

Regular maintenance and appropriate speeds can increase the lifespan of your carbide inserts. Adjusting feeds to suit your material also helps.

What are optimal cutting speeds?

Optimal cutting speed varies with each material, but staying within recommended ranges will lead to better cuts. Check your insert’s guidelines for exact numbers.

Common Challenges and Solutions in Lathe Turning

Addressing issues such as chatter, tool wear, and chip formation. Troubleshooting tips for maintaining cutting efficiency.Lathe turning can be tricky, like trying to teach a cat to fetch! One common issue is chatter, which sounds like a bad drum solo. To fix this, adjust the speed and depth of your cuts. Then, there’s tool wear, which can turn your shiny inserts dull faster than you can say “oops!” Regularly check and replace your tools before they start to look like tiny blades of grass. Lastly, keeping an eye on chip formation helps make smooth parts. If chips are sticking, tweak your feed rate or coolant. Here’s a quick table with troubleshooting tips:

| Challenge | Solution |

|---|---|

| Chatter | Adjust speed and depth |

| Tool Wear | Replace dull inserts |

| Chip Formation | Tweak feed rate and coolant |

Future Trends in Round Carbide Insert Technology

Innovations in insert materials and coatings. Emerging trends in insert design and application.Exciting changes are on the horizon for round carbide insert technology! New materials and advanced coatings are making these inserts tougher and livelier. Think of them as superheroes, fighting wear and tear with style. Design trends are shifting too, focusing on shapes that enhance performance and efficiency. Companies are also exploring unique applications to optimize machining processes. A world of innovation awaits, making lathe turning not just practical, but also fun!

| Innovation | Description |

|---|---|

| Materials | New alloys for stronger durability. |

| Coatings | Advanced coatings reduce friction. |

| Design | Shapes for optimal cutting! |

| Applications | Innovative uses in different industries. |

Case Studies and Real-World Applications

Successful implementations of round carbide inserts in various industries. Lessons learned from professional lathe operators.Round carbide inserts are like the superheroes of the machining world. They’ve been used successfully across various industries, like automotive and aerospace, to create precision parts. With their awesome durability, they help minimize downtime. Professional lathe operators have learned many tricks along the way. For example, regular maintenance of tools keeps them sharper and longer-lasting. Here’s a quick look at some of their findings:

| Industry | Application | Lesson Learned |

|---|---|---|

| Automotive | Engine components | Proper insert selection boosts efficiency. |

| Aerospace | Flight parts | Consistency is key to safety. |

| Medical | Precision devices | Quality control prevents costly mistakes. |

In short, round carbide inserts not only enhance productivity but also teach valuable lessons about care and selection. Remember, a happy lathe leads to happy parts!

Resources for Further Learning

Recommended books, online courses, and industry associations. Links to instructional videos and expert forums.Learning more about lathe turning can be fun and exciting! Here are some great resources to check out:

- Books: Look for books on machining and lathe work.

- Online Courses: Websites like Udemy or Coursera offer lessons.

- Industry Associations: Joining groups like the National Tooling and Machining Association can help.

- Instructional Videos: YouTube has many helpful tutorials.

- Expert Forums: Online communities like Reddit’s machining subreddit are great for questions.

What are some resources for lathe turning?

Check out these materials: Books, online courses, videos, and forums. They will guide you in mastering lathe turning with round carbide inserts! Learning is key!

Conclusion

In summary, lathe turning with round carbide inserts is efficient and precise. These inserts last longer and provide smooth finishes. You can easily shape different materials by using these tools. Remember to practice using them safely and effectively. If you’re interested in learning more, explore videos or guides on lathe techniques. Your skills will grow with every turn!FAQs

Sure! Here Are Five Questions Related To Lathe Turning With Round Carbide Inserts:Sure! Here are five questions about lathe turning with round carbide inserts. 1. **What is a lathe?** A lathe is a machine that spins a piece of metal or wood. It helps us shape that material. 2. **What are carbide inserts?** Carbide inserts are small, hard pieces used to cut materials. They last a long time and make cutting easier. 3. **How do we use a lathe?** We place a material in the lathe, turn it on, and move the tool against it. This helps us shape the material. 4. **Why do we use round inserts?** Round inserts can cut in many directions. They are good for making smooth, curved shapes. 5. **What safety tips should we follow?** Always wear safety goggles and keep fingers away from the machine. Be careful and follow all rules.

Sure! Please provide the specific question you want me to answer.

What Are The Advantages Of Using Round Carbide Inserts For Lathe Turning Compared To Traditional Cutting Tools?Using round carbide inserts for lathe turning has cool benefits. First, they last longer than regular cutting tools, so you don’t have to change them often. They also cut smoothly, which makes better shapes and finishes on your work. Plus, they are easy to switch out, which saves you time. Overall, they help you work faster and get better results!

How Do You Determine The Appropriate Cutting Speed And Feed Rate When Using Round Carbide Inserts On Different Materials?To choose the right cutting speed and feed rate, you need to know the material you’re working with. Softer materials go faster, while harder materials need slower speeds. You also want to check the tool’s instructions for specific numbers. Experimenting a bit helps too. Good practice will help you get better at it!

What Are Some Common Applications For Round Carbide Inserts In Lathe Turning Operations?We use round carbide inserts in lathe turning to shape metal and plastic. They help make parts like bolts, gears, and bearings. You can cut, smooth, or make designs on the surfaces of these materials. They are popular because they stay sharp for a long time. This makes our work faster and more accurate!

How Can You Optimize Tool Life And Performance When Using Round Carbide Inserts In Lathe Turning?To make round carbide inserts last longer in lathe turning, you can follow some simple tips. First, use the right speed and feed rates for your material. This helps the tool cut smoothly and not wear out too fast. Second, keep the inserts clean and sharp. Dirt can cause them to break or wear down. Lastly, check the coolant levels; it keeps the tool cool while you work.

What Factors Should Be Considered When Selecting A Specific Type Of Round Carbide Insert For A Particular Turning Operation?When picking a round carbide insert for turning, you should think about the material. What are you cutting? Different materials need different inserts. Also, consider the shape and size of the insert. Finally, check how fast you’ll be spinning the tool. These choices help you get the best results!