Have you ever dreamed of creating something amazing with your own hands? Imagine the possibilities when you learn how to use a lathe. A lathe is a powerful tool, perfect for shaping metal. If you own a metal lathe bench, you’re already on the right track to becoming a mini-machinist!

In this lathe tutorial, we’ll dive into the basics. You’ll discover how to turn raw materials into finished products. Whether you want to make parts for a project or just enjoy some hands-on fun, this guide will help you get started.

Did you know that using a lathe can help you build skills in problem-solving? It’s true! As you work with metal, you learn to think creatively and carefully. So, are you ready to unlock your potential and explore the world of metalworking?

Lathe Tutorial: Mastering Your Metal Lathe Bench Skills

Discovering Metal Lathe Techniques

Learning metal lathe skills can be fun and rewarding. A lathe tutorial helps users master important techniques for creating precise parts. Did you know that even a simple bench lathe can produce intricate designs? Readers will discover safety tips, essential tools, and step-by-step processes. This knowledge opens the door to various projects. Imagine transforming metal into amazing creations right in your workshop! With practice, even beginners can create professional-looking results. Metal lathes hold endless possibilities!Understanding the Basics of Metal Lathes

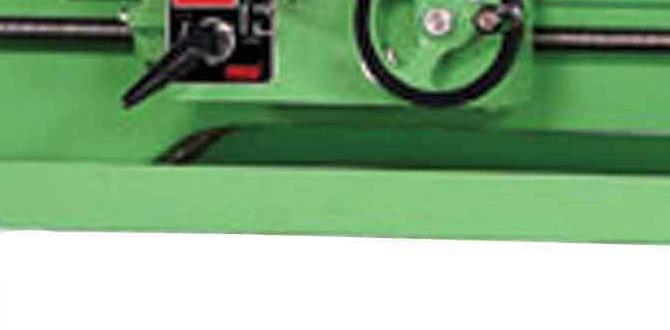

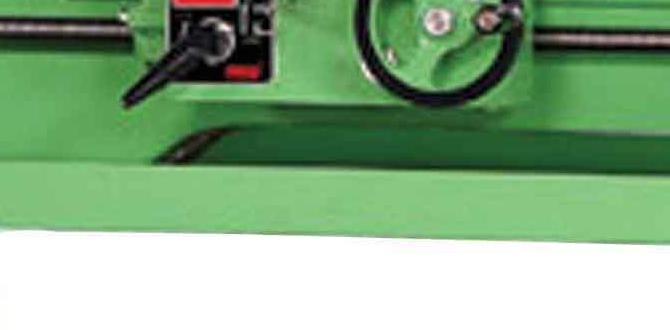

Definition and function of a metal lathe. Key components of a metal lathe explained.Metal lathes are fascinating machines that spin metal to shape it. Think of it as a giant pencil sharpener—only, instead of wood, you’re working with metal! They can create round shapes like cylinders and even help carve designs into the material.

| Key Component | Function |

|---|---|

| Bed | Supports the whole machine, keeping it steady. |

| Headstock | Holds the spindle, powering the spin. |

| Tailstock | Supports the other end of the metal piece. |

| Carriage | Moves the tool against the spinning metal. |

Each part plays a huge role, much like a superhero team. Together, they can create amazing metal parts like you wouldn’t believe! Remember, a metal lathe isn’t just a tool; it’s your ticket to transforming chunks of metal into something great!

Setting Up Your Metal Lathe Bench

Stepbystep guide to properly setting up your workspace. Safety measures to consider during setup.To create a safe workspace for your metal lathe bench, follow these steps. First, find a flat, sturdy surface for your lathe. Make sure it’s free of clutter. Then, secure the lathe properly to prevent movement. Always have safety gear, like goggles and gloves, ready. Remember to:

- Check the power source

- Keeps tools organized

- Light your workspace well

By following these steps, you’ll set up an effective and safe lathe bench.

What safety measures should I take during setup?

It’s important to wear protective gear like goggles and ear protection. Ensure your workspace is clutter-free to avoid accidents. Always lock tools away safely when not in use.

Basic Operations on a Metal Lathe

Explanation of turning, facing, and drilling processes. Detailed instructions for each operation.Using a metal lathe can be fun and educational! First, let’s talk about turning. In this process, the tool moves parallel to the lathe’s spindle, shaping the material into a cylinder. Next is facing, where the tool cuts across the end of the material for a smooth surface—like trimming your hair! Finally, we have drilling, where the tool creates holes in the workpiece. Remember these steps for a smooth finish!

| Operation | Description |

|---|---|

| Turning | Shapes the material into a cylinder. |

| Facing | Trims the end for a smooth surface. |

| Drilling | Creates holes in the material. |

Troubleshooting Common Issues

Identification of frequent problems encountered with metal lathes. Solutions and preventive measures for common issues.Metal lathes can be tricky! Sometimes, they make strange noises or the material turns out all wrong. Common problems include vibrations, uneven cuts, and tool wear. To solve these, check your machine setup first. Tighten loose parts and make sure everything is aligned properly. Use proper tools to reduce wear.

| Problem | Solution |

|---|---|

| Vibrations | Tighten loose bolts and check balance. |

| Uneven Cuts | Adjust the tool height and angle. |

| Tool Wear | Use high-speed steel tools. |

Keep your lathe clean and well-lubricated too. A happy lathe makes a happy craftsman! Remember, if something seems off, always double-check. Better safe than sorry!

Maintenance Tips for Longevity

Routine maintenance practices to prolong lathe life. Cleaning and lubrication best practices.Taking care of your metal lathe is like nurturing a pet! Regular maintenance keeps it happy and working well. Start by cleaning it often. Dust and chips can sneak into places, making it grumpy. Use a soft brush and a vacuum to keep it clean. Don’t forget lubrication! Oil the moving parts to keep everything running smoothly. This reduces noise, too. Follow these simple steps for a long-lasting relationship with your lathe!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Cleaning | Weekly | Use a brush and vacuum! |

| Lubrication | Every month | A little oil goes a long way. |

Resources for Further Learning

Recommended books, online courses, and workshops for skill enhancement. Engaging with the metalworking community for growth and support.Learning more about metal lathe skills can enrich your experience. Here are some great resources to help you.

- Books: “Metalworking for Beginners” is a great start.

- Online Courses: Websites like Coursera and Udemy offer useful classes.

- Workshops: Local shops might have hands-on events.

Engaging with the metalworking community can provide strong support. Join clubs or forums to connect and grow. Sharing ideas can help you learn faster!

What are the best resources for learning metalworking?

The best resources include books, online courses, and local workshops. Joining communities can also support your learning journey.

Conclusion

In conclusion, a lathe tutorial for metal lathes can greatly improve your skills. Understanding the bench setup is crucial for successful projects. Practice safely and experiment with different techniques. Remember to read more guides to deepen your knowledge. With time and effort, you can create impressive metalwork. So, pick up your tools and start turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Tutorials And Bench Setups:Sure! Here are five questions you might ask about metal lathe tutorials and bench setups. 1. What is a metal lathe? A metal lathe is a machine that helps you shape metal. 2. How do you use a metal lathe? You use it by putting a metal piece in and turning on the machine. 3. What tools do you need for a lathe setup? You need tools like cutting bits, wrenches, and safety goggles. 4. How do you stay safe when using a lathe? Always wear goggles and keep your long hair tied back. 5. Where should you put your lathe? You should place it on a sturdy bench where it won’t shake.

Sure! Please provide the question you want me to answer.

What Are The Essential Components And Features To Look For When Selecting A Metal Lathe For A Workshop Bench?When picking a metal lathe for your workshop, look for a strong base. It keeps the lathe steady while you work. Check for a smooth motor; this helps it run quietly. A good chuck (the part that holds the metal) is important too. Finally, make sure it has a simple control panel, so you can use it easily.

How Do You Set Up And Align A Metal Lathe On A Bench To Ensure Optimal Precision And Performance?To set up a metal lathe on a bench, you start by placing it on a flat surface. Make sure the lathe is level. You can use a spirit level to check this. Next, tighten all the bolts so it doesn’t wobble. Finally, adjust the parts of the lathe so they line up correctly for accurate work.

What Are The Key Safety Precautions To Consider When Operating A Metal Lathe In A Workshop Environment?When using a metal lathe, always wear safety glasses to protect your eyes. Tie back long hair and remove loose clothes to avoid getting caught. Keep your hands away from moving parts. Make sure the area is clean and organized to prevent accidents. Lastly, follow all the safety rules and ask for help if you’re unsure.

What Basic Turning Techniques Should Beginners Learn When Starting To Use A Metal Lathe?When you start using a metal lathe, you should learn a few basic turning techniques. First, practice facing, which means cutting a flat end on a piece of metal. Next, try turning, where you shape the metal into a cylinder. Then, learn how to taper, making one end of the metal narrower. Finally, work on drilling holes, which is important for many projects. These skills will help you get better at using the lathe.

How Can One Maintain And Care For A Metal Lathe To Ensure Its Longevity And Reliability?To keep your metal lathe running well, clean it regularly. Use a soft cloth to wipe away dust and oil. Check the parts for wear and replace anything broken. Make sure to oil the moving parts to keep them smooth. Lastly, store it in a dry place to prevent rust.