Have you ever wondered how metal parts are made? Imagine a giant machine spinning metal like a top. This machine is called a lathe. It’s a tool that shapes metal into all sorts of items. In this article, we will dive into the world of lathes and explore how they work.

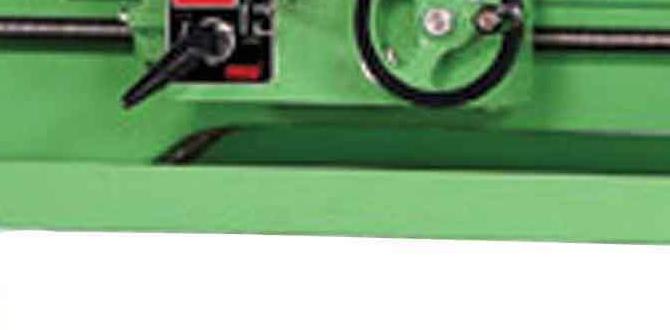

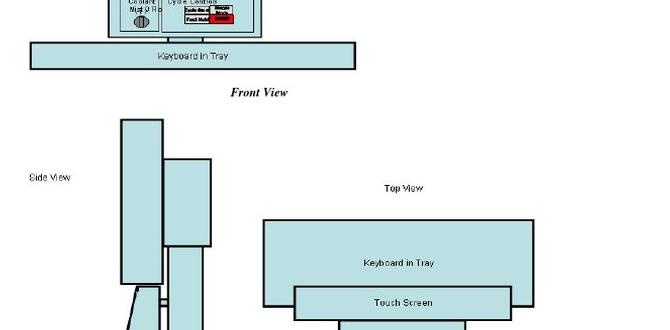

One key part of using a lathe is the control panel. This panel helps the operator manage the machine’s settings easily. Think of it like the dashboard of a car. Just as drivers control their vehicles for a smooth ride, lathe operators use the control panel for precise cuts.

Did you know that lathes have been around for thousands of years? Ancient craftsmen used simple versions of these machines to create beautiful wooden objects. Today, metal lathe tutorial guides can help anyone learn this skill. Whether you’re a hobbyist or someone curious about engineering, mastering a metal lathe can open up a world of possibilities.

Join us as we explore detailed tips on the lathe tutorial and learn how to navigate the metal lathe control panel with ease. Are you ready to turn your ideas into real creations?

Comprehensive Lathe Tutorial: Mastering Metal Lathe Control Panel — **Lathe Tutorial: Metal Lathe Control Panel** The Lathe Is An Essential Tool In Metalworking, Allowing Machinists To Create Precise And Intricate Parts From Metal Stock. Understanding The Metal Lathe Control Panel Is Crucial For Effective Operation. This Article Serves As A Comprehensive Lathe Tutorial, Guiding You Through The Functionalities And Uses Of A Metal Lathe Control Panel. What Is A Metal Lathe? A Metal Lathe Is A Machine Tool That Rotates A Workpiece On Its Axis To Perform Various Operations Such As Cutting, Sanding, Drilling, Or Deforming. It Is Widely Used For Shaping Metals And Is An Indispensable Part Of Any Machining Shop. Overview Of The Control Panel The Control Panel Of A Metal Lathe Is The Central Hub For Operating The Machine. It Typically Consists Of Various Buttons, Switches, And Digital Displays That Provide Real-Time Information And Controls. Familiarizing Yourself With The Control Panel Will Enhance Your Understanding And Efficiency When Working On The Lathe. Key Components Of The Metal Lathe Control Panel 1. **Power Switch**: Turns The Machine On Or Off. 2. **Speed Control**: Adjusts The Rotation Speed Of The Spindle. 3. **Feed Control**: Regulates The Feed Rate Of The Tool Against The Workpiece. 4. **Emergency Stop**: Immediately Halts All Operations In Case Of An Emergency. 5. **Digital Readouts**: Displays Real-Time Measurements, Such As Spindle Speed And Feed Rate. Operating The Metal Lathe Control Panel 1. **Starting Up**: Ensure All Safety Equipment Is In Place And Power On The Machine Using The Power Switch. 2. **Setting Speed**: Adjust The Spindle Speed According To The Material And Tool Being Used. 3. **Configuring Feed Rate**: Set The Feed Rate Appropriate For The Operation To Ensure Quality Cuts. 4. **Monitoring Measurements**: Regularly Check The Digital Readouts To Keep Track Of The Machine’S Performance. Safety Precautions Always Prioritize Safety When Operating A Metal Lathe. Make Sure To: – Wear Appropriate Personal Protective Equipment (Ppe). – Keep Hands Clear Of Moving Parts. – Familiarize Yourself With The Emergency Stop Function. Conclusion Mastering The Metal Lathe Control Panel Is An Essential Skill For Any Machinist. This Lathe Tutorial Has Equipped You With The Knowledge Necessary To Operate The Control Panel Effectively, Ensuring Your Metalworking Tasks Are Performed Accurately And Safely. Happy Machining!

Understanding Metal Lathe Control Panel

Curious about how a metal lathe works? The control panel is essential! It helps users manage speed and direction. Knowing its buttons and functions can make metalworking easier and safer. Did you know that even small changes in settings can greatly affect the final product? Understanding the control panel can take your skills to the next level. Dive into the world of metal lathes and discover how this important tool can enhance your projects!Safety Precautions When Operating a Metal Lathe

Essential safety gear and practices. Common hazards and how to avoid them.Before jumping on the metal lathe, gear up! Safety goggles and a sturdy apron are your best friends. Think of them as your stylish armor. Don’t forget gloves, but not the fluffy kind — we want to avoid any “lathe hugs!” Common hazards include flying metal chips and unwelcome hand injuries. Stay alert and keep your workspace tidy. Check out the table below for quick safety tips:

| Essential Gear | Common Hazards | Prevention Tips |

|---|---|---|

| Safety Goggles | Flying Debris | Always wear goggles! |

| Apron | Clothing Snags | Wear fitted clothes. |

| Work Gloves | Hand Injuries | Use gloves made for machinery. |

Setting Up Your Metal Lathe Control Panel

Stepbystep setup process. Tips for proper alignment and calibration.To get your metal lathe control panel ready, follow these easy steps. First, connect the power supply. Then, hook up the control panel to the machine. Check the wires to avoid any *oopsies*!

Next, align the panel. Make sure it sits straight. If it’s wonky, your lathe might go on an unexpected adventure! Calibration comes next. Adjust settings to match your project. Refer to the table below for a quick checklist:

| Step | Action | Tip |

|---|---|---|

| 1 | Connect power | Double-check the plug! |

| 2 | Attach control panel | Make sure it’s level! |

| 3 | Calibrate settings | No one likes a surprise cut! |

With these steps, your control panel will be ready to go. Happy turning!

Basic Functions of the Control Panel

Explanation of key controls (speed, feed, etc.). How to adjust settings for various materials.The control panel of a metal lathe is like the remote control for a spaceship, minus the space travel! It features key controls such as speed and feed. The speed control lets you change how fast the lathe spins. A higher speed is good for softer materials, like aluminum, while a slower speed works best for harder metals like steel.

Adjusting the feed helps you manage how quickly the tool moves through the material. It’s like setting your walking pace for a marathon—too fast and you’ll tire out quickly! Here’s a handy table that shows basic settings:

| Material | Speed (RPM) | Feed Rate (IPR) |

|---|---|---|

| Aluminum | 1200 | 0.02 |

| Steel | 600 | 0.01 |

Remember, adjusting these controls can ensure your project goes smoothly. After all, nobody likes a wobbly table leg!

Troubleshooting Common Control Panel Issues

Identifying and resolving error messages. Maintenance tips for longevity of the control panel.Errors can pop up on your control panel. It’s key to find and fix them quickly. Look for messages on the screen. Common issues include power loss or unresponsive buttons. Here’s how to keep your control panel running well:

- Check for loose wires.

- Keep it clean and dust-free.

- Update software regularly.

Following these steps helps your control panel last longer. Remember, a little maintenance goes a long way!

How can I troubleshoot control panel error messages?

To troubleshoot error messages, read the display carefully. This will often tell you what’s wrong. If you’re unsure, consult your manual or seek professional help.

Maintenance Tips:

- Inspect wires and connections regularly.

- Keep the panel indoors to avoid weather damage.

Practical Applications of the Metal Lathe Control Panel

Examples of projects and tasks. How control panel settings influence project outcomes.A metal lathe control panel is like the wizard’s wand for machinists. With this magical tool, you can carve everything from cool bike parts to intricate jewelry. Each setting on the panel, such as speed and feed rate, helps shape your project just right. Use the wrong speed, and your masterpiece might look more like a potato! Any adjustment can change the outcome, making every project unique.

| Project | Control Panel Setting | Outcome |

|---|---|---|

| Bike Frame | High Speed | Smooth Finish |

| Jewelry Making | Low Speed | Precise Cuts |

| Custom Parts | Variable Feed Rate | Durability |

Choosing the right control panel settings is like playing a video game. The better you know your tools, the better your score—or in this case, your project! Get ready to turn your metal dreams into reality!

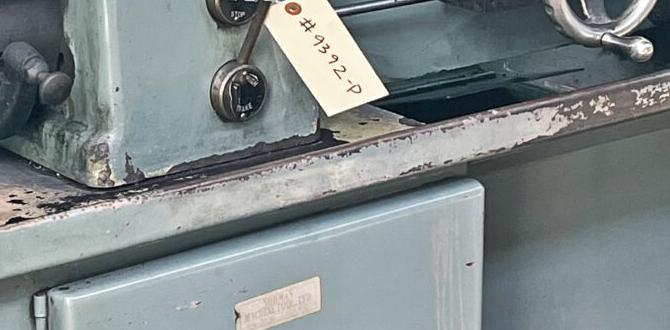

Comparing Different Metal Lathe Models and Their Control Panels

Analysis of popular models on the market. Key differences in functionality and usability.Many models of metal lathes are popular today, each with its unique features. For example, some lathes have digital control panels that light up like a spaceship dashboard! Others keep it classic with dial controls, which can be a bit like using a rotary phone—fun but maybe not everyone’s cup of tea. The tooling options and cutting speed vary too, affecting their usability. Take a look at our table below to see how they stack up:

| Model | Control Panel Type | Cutting Speed | Ease of Use |

|---|---|---|---|

| Model A | Digital | 300-2000 RPM | Easy |

| Model B | Manual | 200-1500 RPM | Moderate |

| Model C | Hybrid | 100-2500 RPM | Very Easy |

Remember, choosing the right lathe depends on your needs!

Tips for Improving Your Metal Lathe Skills

Recommended practices for beginners and seasoned users. Resources for further learning and development.To enhance your skills with a metal lathe, practice is key. Beginners should focus on understanding the lathe control panel and its settings. Always start with simple projects. Seasoned users can refine their techniques by experimenting with new materials.

Here are some great tips:

- Take notes on what works and what doesn’t.

- Watch online tutorials for new ideas.

- Join a local maker group or online forum.

Using good resources can also help. Books, videos, and workshops are excellent ways to learn more. Remember, the more you practice, the better you’ll get!

What are some effective resources for learning about metal lathes?

Some helpful resources include online video tutorials, books on machining, and local workshops. These offer hands-on experience and expert tips that can boost your skills.

Conclusion

In conclusion, mastering the control panel on a metal lathe is essential for smooth operation. You can adjust speeds and settings easily with practice. Remember to always follow safety rules while working. Consider watching detailed lathe tutorials online for hands-on learning. By building your skills, you’ll become more confident in using a lathe for your projects. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Metal Lathe Control Panels:Sure! A metal lathe control panel helps you run a machine that shapes metal. It has buttons and switches you use to change settings. You will find dials to adjust speed and power. Learning how to use these controls is important for safety and getting good results. Always follow instructions when using the panel!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Key Components Of A Metal Lathe Control Panel, And What Functions Do They Serve?A metal lathe control panel has some important parts. First, there is a power switch to turn the machine on or off. Next, you’ll find buttons to control the speed of the tool. There are also knobs to change the direction of the lathe. Finally, there are emergency stop buttons to keep everyone safe.

How Can A User Troubleshoot Common Issues On A Metal Lathe Control Panel, Such As Error Messages Or Malfunctions?If you see an error message on the metal lathe control panel, don’t worry! First, check the power supply; make sure it’s plugged in. Then, look at the display for any specific codes or messages. You can usually find help for those in the user manual. If the machine still doesn’t work, try turning it off and on again.

What Safety Features Should Be Included On A Metal Lathe Control Panel To Protect Operators During Use?A metal lathe control panel should have important safety features. You should see a big emergency stop button. This button halts the machine quickly if there’s a problem. There should also be clear warning lights that show when the lathe is running. Finally, a cover or shield can protect you from flying bits of metal while you work.

How Does The Programming Interface Of A Cnc Metal Lathe Control Panel Differ From A Manual Lathe Control Panel?A CNC (Computer Numerical Control) metal lathe has a screen and buttons you can use to type in commands. You can set up everything using a computer system, which makes it easy to create complex shapes. A manual lathe, on the other hand, uses levers and dials that you turn by hand to control the machine. This means you need to control everything yourself, which can take more time. CNC lathes can run automatically once you set them up.

What Are Some Tips For Beginners To Effectively Read And Understand The Settings On A Metal Lathe Control Panel?To understand a metal lathe control panel, start with the labels. Look at what each knob or button does. You can write down what you find. Don’t rush; take your time to learn. If something is confusing, ask someone for help. Always practice at a safe speed. With time, you will get better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe control panel helps you run a machine that shapes metal. It has buttons and switches you use to change settings. You will find dials to adjust speed and power. Learning how to use these controls is important for safety and getting good results. Always follow instructions when using the panel!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Control Panel, And What Functions Do They Serve?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel has some important parts. First, there is a power switch to turn the machine on or off. Next, you’ll find buttons to control the speed of the tool. There are also knobs to change the direction of the lathe. Finally, there are emergency stop buttons to keep everyone safe.”}},{“@type”: “Question”,”name”: “How Can A User Troubleshoot Common Issues On A Metal Lathe Control Panel, Such As Error Messages Or Malfunctions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you see an error message on the metal lathe control panel, don’t worry! First, check the power supply; make sure it’s plugged in. Then, look at the display for any specific codes or messages. You can usually find help for those in the user manual. If the machine still doesn’t work, try turning it off and on again.”}},{“@type”: “Question”,”name”: “What Safety Features Should Be Included On A Metal Lathe Control Panel To Protect Operators During Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel should have important safety features. You should see a big emergency stop button. This button halts the machine quickly if there’s a problem. There should also be clear warning lights that show when the lathe is running. Finally, a cover or shield can protect you from flying bits of metal while you work.”}},{“@type”: “Question”,”name”: “How Does The Programming Interface Of A Cnc Metal Lathe Control Panel Differ From A Manual Lathe Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC (Computer Numerical Control) metal lathe has a screen and buttons you can use to type in commands. You can set up everything using a computer system, which makes it easy to create complex shapes. A manual lathe, on the other hand, uses levers and dials that you turn by hand to control the machine. This means you need to control everything yourself, which can take more time. CNC lathes can run automatically once you set them up.”}},{“@type”: “Question”,”name”: “What Are Some Tips For Beginners To Effectively Read And Understand The Settings On A Metal Lathe Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To understand a metal lathe control panel, start with the labels. Look at what each knob or button does. You can write down what you find. Don’t rush; take your time to learn. If something is confusing, ask someone for help. Always practice at a safe speed. With time, you will get better!”}}]}