Have you ever wondered how a simple piece of metal can become a beautiful shape? A lathe does that magic! In this lathe tutorial, we’ll explore the metal lathe drive system. You might think, “What’s a drive system?” Well, it’s the heart of the lathe, helping to turn the metal smoothly.

Imagine holding a rough piece of metal. Now, picture it spinning fast and changing shape before your eyes. It’s like watching a sculptor at work! The drive system makes this possible. It’s an exciting part of the lathe that many people don’t think about.

Here’s a fun fact: Did you know that the lathe is one of the oldest tools used by humans? It’s true! People have been using it for thousands of years to create everything from potters’ clay to high-tech machine parts.

In this article, you will learn the basics of the drive system. By the end, you’ll understand why it matters. So, are you ready to dive into the world of metal lathes? Let’s get started!

Lathe Tutorial: Understanding Metal Lathe Drive Systems

Lathe Tutorial: Metal Lathe Drive System

A metal lathe drive system is vital for shaping materials like metal and wood. Understanding how it operates can help hobbyists and professionals alike. Did you know that a basic lathe can turn a simple block of metal into a finely crafted instrument? In this tutorial, you’ll learn about the components that make up the drive system, like belts and pulleys. You’ll also discover how to maintain your lathe for better performance. Ready to give your projects a new spin?Types of Drive Systems in Metal Lathes

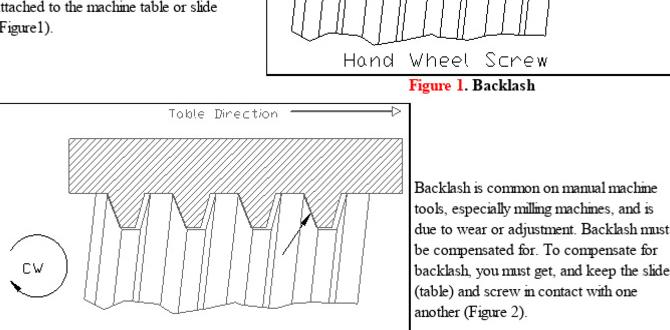

Description of different drive systems (gear, belt, direct drive). Advantages and disadvantages of each type.Metal lathes can have different drive systems, each with its own quirks. The **gear drive** is like a fast car—it offers precision and power but can be noisy. Next, we have the **belt drive**; it’s quieter and absorbs shocks like a sponge but might slip if you’re not careful. Finally, there’s **direct drive**, which is smooth and simple, yet sometimes lacks the torque for heavy tasks. Knowing these can help you pick the right one for your metal marvel!

| Drive System | Advantages | Disadvantages |

|---|---|---|

| Gear Drive | Precise, powerful | Noisy |

| Belt Drive | Quiet, shock-absorbing | Can slip |

| Direct Drive | Smooth, simple | Less torque |

Components of a Metal Lathe Drive System

Detailed explanation of key components (motor, pulleys, gears). How each component contributes to the system’s functionality.A metal lathe has key parts that work together. They include the motor, pulleys, and gears. Each of these components plays an important role. The motor gives the power to turn the lathe. The pulleys and gears then help control the speed and movement. Together, they create precise cuts and shapes in metal.

- Motor: Provides the driving force for the machine.

- Pulleys: Transfer power from the motor to the lathe.

- Gears: Control the speed and direction of the lathe’s movement.

What Do Components of a Metal Lathe Drive System Do?

The motor makes the lathe spin. The pulleys connect the motor, helping it move the machine. Lastly, the gears allow you to change how fast the lathe turns. Each part works together to make shaping metal easier.

Setting Up Your Lathe Drive System

Stepbystep guide for assembling the drive system. Common mistakes to avoid during setup.First, gather your parts like a treasure hunter. You’ll need the motor, pulleys, and belts. Start by attaching the motor tightly so it doesn’t do the cha-cha during operation. Next, connect the pulleys and ensure they align. A misaligned pulley is like a sock with a hole—it just doesn’t work!

| Common Mistakes | How to Avoid Them |

|---|---|

| Pulleys not aligned | Double-check that everything lines up before tightening. |

| Loose connections | Always tighten screws snugly—but don’t Hulk-smash them! |

Finally, plug it in and give it a test spin, but keep your fingers clear! 🎉 Remember, setting up your lathe drive system correctly can keep your projects running smoothly and prevent strange noises—like my dog when he wants a snack!

Maintenance of the Drive System

Importance of regular maintenance checks. Recommended practices for prolonging the life of your drive system.Maintaining your drive system is very important. Regular checks help find problems early. This can save time and money. Here are some recommended practices:

- Inspect belts and pulleys for wear.

- Keep parts clean and free from dust.

- Lubricate moving parts regularly.

- Check for loose screws and bolts.

These simple steps can help your drive system last longer and work better. Remember, a well-maintained system can boost performance significantly!

Why is regular maintenance important?

Regular maintenance keeps your drive system running smoothly and safely. It can help avoid major repairs in the future, saving time and expense.

Troubleshooting Common Drive System Issues

Identification of frequent problems and their causes. Solutions and tips for effective troubleshooting.Sometimes, the drive system of a metal lathe can act up. This can make your project feel like a frustrating game of hide-and-seek. Some common issues include strange noises, slipping belts, and sudden stops. These annoyances often come from loose bolts or worn-out parts. The best way to tackle these problems? Regular checks! Keep everything tight and well-lubricated. If you encounter a major hiccup, consult the manual—it’s like having a cheat sheet! Below are some tips to help:

| Issue | Possible Cause | Solution |

|---|---|---|

| Strange Noises | Worn bearings | Replace or lubricate |

| Slipping Belt | Loose tension | Adjust tension |

| Sudden Stops | Electrical issues | Check wiring and connections |

By staying on top of these tips, you’ll have a smoother experience. Remember, a happy lathe makes a happy worker!

Upgrading Your Metal Lathe Drive System

Signs that an upgrade is necessary. Popular upgrade options and their benefits.Upgrading your drive system can boost your lathe’s performance. Look for signs like loud noises, vibrations, or sluggish movements. These may mean it’s time for an upgrade. Popular options include:

- Brushless DC Motors: Quieter and more efficient.

- Variable Frequency Drives (VFD): Offer adjustable speeds for better control.

- Mechanical Belt Drives: Improve torque and reduce wear.

These upgrades enhance durability and precision, making your work easier and more enjoyable.

What signs show I need to upgrade my lathe drive system?

Signs of needing an upgrade include strange noises, vibrations, or slow operation. If you notice any of these, consider an upgrade for better performance.

Safety Considerations When Using Lathe Drive Systems

Key safety protocols to follow. Importance of personal protective equipment (PPE).Using lathe drive systems can be fun, but safety should always come first. Follow key safety protocols like keeping your workspace tidy and ensuring all tools are well-maintained. Don’t forget to wear your Personal Protective Equipment (PPE)! This includes safety glasses and ear protection—your ears will thank you for it later. Remember, a lathe can be dangerous, but with the right safety measures, you can avoid turning yourself into a human pretzel!

| Safety Protocols | PPE |

|---|---|

| Keep the area clean | Safety glasses |

| Inspect tools regularly | Ear protection |

| Secure loose clothing | Gloves (if safe) |

Resources for Further Learning

Recommended books and online courses. Communities and forums for metal lathe enthusiasts.Need more help with metal lathes? You’re in luck! There are many great resources out there. Check out books like “Metalworking 101” for tips and tricks. Online courses from sites like Udemy are also gems if you want to learn at home. Don’t forget about friendly communities like Reddit’s Metalworking subreddit. They’re like a support group but with more chips and less drama!

| Resource Type | Recommendation |

|---|---|

| Books | Metalworking 101 |

| Online Courses | Udemy Metal Lathe Classes |

| Forums | Reddit: Metalworking |

Conclusion

In conclusion, a lathe tutorial helps you understand metal lathe drive systems. You learn how different components work together. Knowing this can improve your projects and skills. We encourage you to explore more tutorials and practice on your own lathe. The more you learn, the better you’ll become. Keep experimenting and have fun with your metalworking journey!FAQs

What Are The Main Components Of A Metal Lathe Drive System, And How Do They Work Together To Create Rotation?A metal lathe drive system has three main parts. First, the motor gives power to the lathe. Then, the belts connect the motor to the spindle, which is the part that spins. Finally, when you turn on the motor, it sends energy through the belts to make the spindle rotate. This rotation helps us shape and cut metal.

How Can You Troubleshoot Common Issues With A Metal Lathe Drive System, Such As Irregular Speeds Or Vibrations?To troubleshoot a metal lathe drive system, start by checking the power source. Make sure it’s plugged in and working. Next, look for loose parts or connections. Tighten anything that seems wobbly. Lastly, listen for strange sounds and watch for vibrations. If you find anything unusual, repair it or ask for help.

What Are The Advantages Of Using A Variable Speed Drive System In A Metal Lathe Compared To A Fixed Speed Drive?A variable speed drive system lets you change how fast the metal lathe spins. This is helpful because different tasks need different speeds. You can work more easily and make better parts. It also saves energy and helps the machine last longer. Overall, it gives you more control and makes your work easier!

How Do The Different Types Of Drive Systems (Gear-Driven, Belt-Driven, Or Direct Drive) Affect The Performance And Versatility Of A Metal Lathe?Different drive systems change how a metal lathe works. Gear-driven systems give strong power and good control, which is great for precise cuts. Belt-driven systems are quieter and allow you to change speeds easily, making them good for various tasks. Direct drive systems are simple and efficient, often needing less maintenance. Each type of drive helps the lathe do different jobs better!

What Safety Precautions Should Be Taken When Operating Or Maintaining The Drive System Of A Metal Lathe To Avoid Accidents?When using a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and remove any loose clothing. Make sure your hands are clear of moving parts while the machine is running. Turn off the machine and unplug it before doing any maintenance. Finally, always follow the instructions and ask an adult if you’re unsure.