Have you ever watched someone turn a piece of metal into a smooth cylinder? It’s fascinating! Metal lathes are amazing machines that can do just that. They shape and cut metal with precision, making them vital in many workshops.

Do you know what makes a metal lathe work so well? The answer is in its gear train! This system of gears controls the speed and movement of the lathe. You might be surprised to learn that with a few simple steps, anyone can understand how this gear train operates.

So, why should you care about lathe tutorials? Learning to use a metal lathe can unlock a world of creativity. You can create cool projects like tools, parts, or even art. Imagine making something from scratch with your own hands!

This article will guide you through the basics of a lathe tutorial. You’ll discover how the gear train works and how you can use it. Get ready to dive into the exciting world of metalworking!

Comprehensive Lathe Tutorial For Metal Lathe Gear Train

Lathe Tutorial Metal Lathe Gear Train

Discover how to master a metal lathe with this engaging lathe tutorial. Learn about the gear train, a vital component that helps control speed and torque. Ever wondered how different gears affect performance? Understanding the gear train transforms your projects. You will see how choices impact the quality of cuts. Plus, with practice, you can create precise shapes and designs. The right gear setup empowers your creativity. Get ready to explore endless possibilities in metalworking!The Gear Train in Metal Lathes

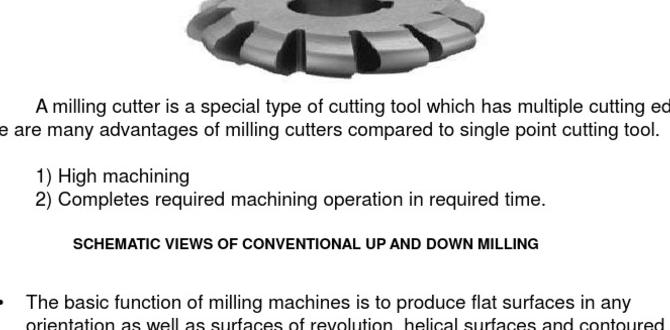

Definition and function of a gear train in the context of metal lathes.. Key components of the gear train system..A gear train is a group of gears working together in a metal lathe. Its main job? To control the speed and torque of the lathe. Think of it as a team of tiny superheroes, each playing a part to make turning metal a breeze.

The gear train consists of key components like gears, shafts, and bearings. Here’s a quick look at their roles:

| Component | Function |

|---|---|

| Gears | Transfer power and rotation. |

| Shafts | Connect gears and transmit motion. |

| Bearings | Support rotating parts and reduce friction. |

In simpler terms, without a gear train, your lathe would be like a car without wheels—going nowhere fast! Keep your gears happy, and they’ll do the heavy lifting for you.

Types of Gear Trains Used in Metal Lathes

Comparison of different gear train configurations (e.g., simple, compound).. Advantages and disadvantages of each type..Gear trains are important in metal lathes. They control speed and power. There are two main types: simple and compound.

- Simple Gear Train:

- Easy to set up.

- Less space needed.

- Lower cost.

- Compound Gear Train:

- More complex design.

- Higher efficiency.

- Can give more speed options.

Simple gear trains are great for beginners. They are easy to understand. Compound gear trains are better for advanced users. They offer flexibility but are harder to manage. Choose the right type based on your needs.

What are the advantages of different gear trains?

Simple gear trains are straightforward and cost-effective, while compound gear trains provide enhanced performance with more options. Each type serves different needs.

Setting Up the Gear Train

Stepbystep instructions on how to set up a gear train for various lathing tasks.. Common mistakes to avoid during setup..To set up a gear train for your metal lathe, follow these steps: First, choose the right gears for your tasks. Next, assemble them on the machine. Make sure they align perfectly. Finally, test the setup before you start working. Avoid these common mistakes:

- Failing to check gear alignment.

- Ignoring gear wear and tear.

- Skipping the test run.

These steps will help ensure a smooth lathe experience!

What is the importance of setting up the gear train correctly?

Setting up the gear train correctly is crucial for precision and efficiency. A well-aligned gear train makes lathing tasks easier and safer. It helps you achieve the best results every time.

Adjusting Gear Ratios for Desired Outcomes

Understanding gear ratios and how they affect lathe performance.. Techniques for calculating and adjusting gear ratios effectively..Gear ratios play a big role in how a lathe works. They help control speed and power. A higher gear ratio means more speed and less torque. To adjust gear ratios, follow these steps:

- Identify current gear ratios.

- Decide the speed or torque you need.

- Use the ratio formula: Input Gear Teeth/Output Gear Teeth.

- Change the gears accordingly.

Understanding these will help you improve lathe performance for your projects.

What are gear ratios in a lathe?

Gear ratios in a lathe determine how fast the machine spins. They affect cutting speed and precision. A useful gear ratio can make your work easier and faster.

Maintenance of Gear Trains in Metal Lathes

Best practices for maintaining gear trains for optimal performance.. Signs of wear and tear to watch for and how to address them..To keep your gear trains running well, regular maintenance is key. Check the gears for loose parts and noise. Clean the gears to avoid dirt buildup. Lubricate them with the right oil. This helps them move smoothly and last longer. Here are some signs of wear and tear:

- Unusual noises

- Visible damage

- Difficulty in movement

If you see these signs, fix them quickly. Replace worn parts to keep everything working smoothly. This ensures good performance for your metal lathe.

What is the best way to maintain gear trains?

Regular cleaning, lubrication, and inspection are crucial for gear train maintenance. Always check for damage or unusual sounds during use.

Applications of Gear Trains in Metal Lathe Projects

Examples of projects and tasks that utilize gear trains effectively.. Reallife case studies showcasing successful gear train applications..Many exciting projects use gear trains in metal lathes. For instance, they help cut intricate shapes and designs. An artist might create beautiful sculptures. Gear trains also assist in making precise parts for machines. They can improve the speed and efficiency of tasks. Here are some successful examples:

- Automobile engine components

- Custom-made tools and jigs

- Specialized fixtures for different jobs

These projects show how gear trains improve metal lathe work and open up new creative possibilities.

What are some common projects using gear trains?

Common projects include engine parts, custom tools, and specialized fixtures.

Common Troubleshooting Tips

Identification of frequent issues related to the gear train in metal lathes.. Stepbystep troubleshooting techniques to resolve these issues..Metal lathes can have issues with their gear trains. These problems can slow down your work. Here are some common issues you might face:

- Strange noises during operation.

- Inaccurate cuts or feeds.

- Slipping gears.

To fix these, follow these steps:

- Check for loose components.

- Inspect the gears for wear and tear.

- Lubricate moving parts properly.

Regular maintenance can help you avoid many of these issues. Keeping your lathe in good shape saves time and effort.

What are common gear train problems in metal lathes?

Common problems include odd noises, slipping, or incorrect cuts. Regular checks can help catch issues early.Conclusion

In conclusion, learning about a lathe tutorial helps you understand metal lathe gear trains. These gears control the machine’s speed and torque. As you practice, you’ll improve your skills and gain confidence. Don’t forget to explore more tutorials and videos for hands-on learning. Start your journey today, and discover the exciting world of metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Tutorial Focusing On Metal Lathe Gear Trains:Sure! A metal lathe is a machine that turns metal to make shapes. Gear trains help control how fast the lathe spins. You can change the gears to get different speeds for different jobs. Using the right gear is important to keep your project safe and neat. Let’s learn how to use them!

Sure! Please provide the specific question you want me to answer.

What Is The Purpose Of A Gear Train In A Metal Lathe, And How Does It Affect The Machining Process?A gear train in a metal lathe helps control the speed and movement of the machine. It changes how fast the tool spins and how the metal moves. This control helps us create better shapes and sizes. With the right speed, we can make smoother cuts and improve our work. So, the gear train is important for making good pieces of metal!

How Can You Adjust The Gear Ratios In A Metal Lathe’S Gear Train To Achieve Different Spindle Speeds?To change the spindle speeds on a metal lathe, you can adjust the gears in the gear train. Gears work in pairs, and you can switch to larger or smaller gears. When you use a bigger gear, the spindle spins slower. When you use a smaller gear, the spindle spins faster. This way, you can choose how fast you want the lathe to work!

What Are The Common Types Of Gear Trains Used In Metal Lathes, And How Do They Differ In Functionality?Metal lathes use different types of gear trains to help them work. Common ones are the spur gear, bevel gear, and worm gear. A spur gear is simple and good for straight movements. Bevel gears can change directions, making them useful for angles. Worm gears help turn things slowly but with a lot of force. Each type helps the lathe do different jobs better.

How Do You Troubleshoot Issues With A Metal Lathe’S Gear Train, Such As Excessive Noise Or Difficulty In Changing Speeds?To fix problems with a metal lathe’s gear train, first, check for loose parts. You can tighten any bolts or screws you find. Next, listen for strange noises and look for worn gears. If you hear clunks, some gears might need replacing. Finally, make sure the lubricant is fresh, so everything moves smoothly.

What Are The Safety Considerations To Keep In Mind When Working With The Gear Train Of A Metal Lathe During Setup And Operation?When working with the gear train of a metal lathe, you need to stay safe. Always wear safety glasses to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Make sure the machine is turned off before you touch anything. Finally, only use tools that are in good shape.