Have you ever wondered how metal parts are made with such precision? A lathe can do just that! In this lathe tutorial, we will explore the amazing world of metal lathes and their power feed feature.

Using a metal lathe might sound tricky, but it is simpler than you think. Just imagine shaping a solid piece of metal into tools, toys, or even art! With the right guidance, you can master this useful machine.

Did you know that metal lathes have been around for centuries? They help turn raw metal into finished products in workshops all over the world. With a power feed, this process becomes even smoother and easier.

Are you excited to learn how to use a metal lathe and its power feed? By the end of this article, you will be ready to take on your own projects. Let’s get started and turn your ideas into reality!

Comprehensive Lathe Tutorial: Mastering Metal Lathe Power Feed

Discover how a metal lathe power feed can make your projects easier and more efficient! With the right tutorial, you’ll learn how to set up your lathe for automatic feeding. This means less manual work and more precision. Imagine smoothly cutting metal while your machine does the hard part. You’ll also find tips on troubleshooting common issues. Who wouldn’t want to create flawless pieces with less effort? Get ready to transform your metalworking skills!

Understanding Metal Lathes

Definition and purpose of metal lathes. Different types of metal lathes and their functions.

Metal lathes are machines that help shape metal. They cut, drill, and finish metal pieces. People use them in factories and workshops. There are different types of metal lathes. Each has a special job:

- Engine Lathes: Common for general tasks.

- Turret Lathes: Quick for repetitive work.

- CNC Lathes: Computer-controlled for precision.

Metal lathes make it easier to create parts for cars, tools, and machines. They help turn raw metal into useful items. Understanding these machines is important for many skilled jobs.

What is the purpose of a metal lathe?

The purpose is to shape metal parts into desired forms for various uses.

What types of metal lathes exist?

There are engine lathes, turret lathes, and CNC lathes, each serving different functions.

Components of a Metal Lathe

Key parts of a metal lathe explained. Importance of each component in operation.

A metal lathe consists of several key parts, each with a special task. The bed is the backbone, keeping everything sturdy. The headstock houses the motor and spindle, spinning the workpiece like a top. The tailstock supports tools and adds stability. It’s like the little brother holding your hand during a bike ride, but you don’t need the training wheels! The carriage moves the tools, making smooth cuts. Together, they work like an orchestra to create perfect metal shapes. Here’s a quick look at these components:

| Component | Function |

|---|---|

| Bed | Supports all parts and keeps everything aligned |

| Headstock | Holds the motor and spins the material |

| Tailstock | Supports tools and workpieces |

| Carriage | Moves tools for cutting |

Understanding these components helps you see how they work together. Each part is important. Without them, your metal lathe would be as useful as a toaster in a swimming pool!

Setting Up Your Metal Lathe for Power Feed

Stepbystep guide to configuring the machine. Safety precautions to consider during setup.

Configuring your metal lathe for power feed can be easy and fun! Start by checking if the power supply is turned off. Safety first, right? Next, read the manual for specific instructions. Now, attach the power feed unit to your lathe with care. Make sure everything is snug, as loose parts can lead to accidents. Once done, double-check your setup before turning the power back on. Remember, even machines like a good check-up!

| Step | Action |

|---|---|

| 1 | Turn off the power supply. |

| 2 | Read the lathe’s manual. |

| 3 | Attach the power feed unit. |

| 4 | Check all connections. |

| 5 | Turn the power back on. |

Always wear safety goggles and keep long hair tied back. You don’t want it getting caught in the machine! So, let’s make sure your lathe is ready for the day without turning it into a rollercoaster ride!

Operating the Power Feed on a Metal Lathe

Detailed instructions on engaging the power feed mechanism. Common mistakes to avoid while using power feed.

To use the power feed on a metal lathe, follow these steps:

- First, ensure the lathe is turned off.

- Engage the power feed switch.

- Adjust the feed rate dial to your desired speed.

- Check the direction of the feed.

- Start the lathe carefully.

Avoid these common mistakes:

- Don’t engage the feed with the lathe running.

- Make sure the dial is set correctly before starting.

- Watch for any unusual noises during operation.

How do you engage the power feed on a metal lathe?

You engage the power feed by turning on the switch, adjusting the feed rate, and starting the lathe. Always remember to do this safely and correctly for best results!

Tips for Effective Use of Power Feed

Best practices for maximizing efficiency with power feed. Recommended speeds and feeds for various materials.

Using the power feed effectively can speed up your work on a lathe. Here are some tips to help you get the best results:

- Choose the right speed: Adjust the speed based on the material. For soft metals, use higher speeds. Hard materials need slower speeds.

- Set proper feeds: A common feed rate is 0.005 to 0.015 inches per revolution. Adjust it for the best finish.

- Keep it clean: Always keep the lathe and tools clean. Dirt can cause problems.

- Be patient: Take your time. Rushing can lead to mistakes.

What should be the speed and feed for different materials?

For aluminum, use speeds around 1,500 RPM and feeds of 0.012 inches per revolution. For steel, try 600 RPM and 0.005 inches per revolution. Adjust based on your specific project.

Troubleshooting Common Power Feed Issues

Identifying and diagnosing common problems. Solutions for common power feed malfunctions.

Power feed issues can be tricky, but don’t worry. First, let’s find out what’s wrong. Common signs of trouble include:

- Inconsistent speed.

- Strange noises.

- Power not engaging.

To fix these problems, you can try:

- Checking connections to ensure they are secure.

- Lubricating moving parts.

- Adjusting the feed speed settings.

With these tips, you’ll keep your lathe running smoothly!

What should I do if my lathe stops moving?

If your lathe stops moving, first check the power switch. Make sure it’s on. If it is, inspect the power cord for damage. Also, look for any blockages in the path. A simple fix often works!

Enhancements and Upgrades for Metal Lathes

Optional accessories to improve power feed functionality. Upgrading electric motors for better performance.

Sprucing up a metal lathe can make turning metal feel like a breeze! Adding optional accessories, like power feed kits, can give you smoother cuts and save your arms from workout sessions. Imagine letting the machine do the heavy lifting while you sip coffee! Upgrading to a beefier electric motor can boost performance, making your lathe a speed demon. Just think, you might turn metal faster than a cheetah on roller skates!

| Accessory | Benefit |

|---|---|

| Power Feed Kit | Effortless metal feeding |

| Upgraded Motor | Increased speed and torque |

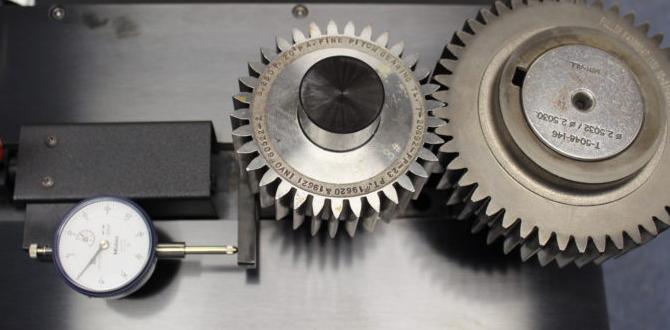

Maintenance of Metal Lathes and Power Feed Systems

Routine maintenance tasks to ensure longevity. Importance of lubrication and cleaning in performance.

Keeping your metal lathe and power feed systems in great shape is crucial for lasting performance. Regular maintenance can save time and money. Focus on these easy tasks:

- Check belts and gears for wear.

- Clean dust and debris from surfaces.

- Inspect electrical connections.

Lubrication is key to smooth operation. Apply oil where needed to prevent sticking parts. Regular cleaning helps machines run better. A clean lathe cuts more accurately and lasts longer. Always remember: a little maintenance goes a long way!

Why is regular maintenance important?

Regular maintenance ensures your lathe works well and lasts longer. It saves you from costly repairs and keeps your projects on track. Equipment care is like getting a check-up; it helps find problems early.

Resources for Further Learning

Recommended books, online courses, and communities for lathe enthusiasts. Useful tools and software for advanced metalworking techniques.

If you’re excited to dive deeper into the world of lathe work, there are plenty of resources to help you out! Recommended books cover everything from basics to advanced techniques, making sure your skills get a workout. Online courses are like virtual classrooms where you can learn at your own pace, even in your pajamas. Communities of fellow lathe lovers can be found online, ready to share tips and laugh together over metal chips!

| Resource Type | Examples |

|---|---|

| Books | The Metal Lathe, Lathe Work: A Complete Guide |

| Online Courses | Udemy, Coursera |

| Communities | Reddit Metalworking, Facebook Groups |

For advanced techniques, don’t forget to check out specialized software. Tools like CAD can help you design with precision. It’s like having a robot buddy, minus the calories! With these resources, your lathe skills will be sharper than your tools.

Conclusion

In this lathe tutorial, we learned how to use a metal lathe with power feed effectively. You now know the basic setup, safety steps, and how to achieve smooth cuts. Remember, practice makes perfect! Try using your lathe on small projects to build your skills. For more tips and techniques, keep exploring other tutorials and guides. Happy machining!

FAQs

What Is The Purpose Of The Power Feed Mechanism On A Metal Lathe, And How Does It Enhance Machining Efficiency?

The power feed mechanism on a metal lathe helps move the cutting tool automatically. This means you don’t have to push it by hand. It makes machining faster and smoother. You get better results without getting tired. Overall, it helps you work more efficiently!

How Do You Set Up And Adjust The Power Feed On A Metal Lathe For Different Cutting Applications?

To set up the power feed on a metal lathe, first, choose the type of cut you want to make. Next, adjust the speed of the feeds by turning the knobs on the machine. If you want a faster cut, increase the speed, and for a slower, more careful cut, decrease it. Always check the tool and material to make sure the settings fit. Finally, test your settings on a scrap piece before starting the real work!

What Are The Common Types Of Power Feed Systems Used In Metal Lathes, And What Are Their Advantages And Disadvantages?

There are two common power feed systems in metal lathes: the mechanical feed and the hydraulic feed. The mechanical feed uses gears and motors to move the tool. It’s reliable and easy to fix, but it can be noisy. The hydraulic feed uses liquids to move the tool. It’s smoother and quieter, but it can be more complicated and hard to repair. Each system has its good and bad points, depending on what you need.

How Can You Troubleshoot Issues With The Power Feed On A Metal Lathe, Such As Inconsistent Feed Rates Or Failure To Engage?

To troubleshoot power feed problems on a metal lathe, first check the power switch to make sure it is on. Next, look at the feed gear for any broken parts or dirt. You can also check the wires to see if they are loose or damaged. If it’s still not working, try adjusting the feed rate settings. If these steps don’t fix it, ask a teacher or an expert for help.

What Safety Precautions Should Be Taken While Operating A Metal Lathe With A Power Feed Feature?

When you use a metal lathe with a power feed, always wear safety glasses. Keep your hair tied back and wear tight clothing. Never touch the moving parts while the lathe is running. Make sure your hands are away from the machine. Finally, keep your workspace clean and organized.