Have you ever wondered how machines create perfect shapes from solid metal? A lathe is one of those amazing tools. It spins metal while a sharp tool cuts it into form. But there’s more to it than just spinning and cutting!

Understanding how to set up a lathe can feel tricky. Many beginners get confused with the metal lathe wiring diagram. But don’t worry! This article is here to help you navigate that with ease. Imagine completing your first project without any guesswork—that’s what we aim for.

Did you know that lathes have been around since ancient times? Craftspeople used them as early as 1300 BC! It’s fascinating to think how this tool evolved into what it is today.

Ready to dive in? Let’s explore the essential steps to understand your lathe better and master that wiring diagram together!

Essential Lathe Tutorial: Metal Lathe Wiring Diagram Explained

Lathe Tutorial Metal Lathe Wiring Diagram

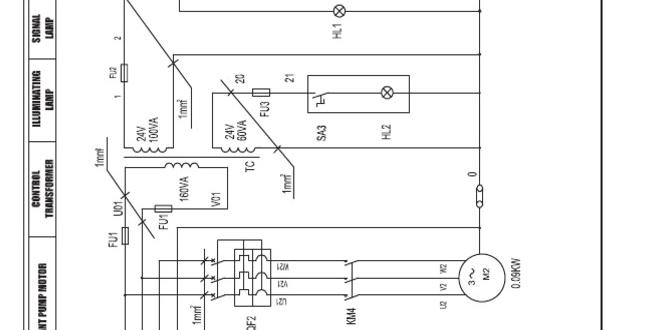

Understanding metal lathe wiring can feel tricky. A clear wiring diagram helps simplify this process. Key points in a lathe tutorial explain how to connect various components safely and effectively. Readers learn important safety tips and common wiring mistakes to avoid. Each step builds confidence in a beginner’s skills. Did you know that a well-wired lathe can improve your project results? Grasping these concepts opens the door to creating fantastic metalworks!What is a Metal Lathe?

Definition and purpose of a metal lathe. Common applications in various industries.A metal lathe is a machine that shapes metal using a rotating workpiece and a cutting tool. Picture a giant pencil sharpener that makes metal parts instead of wood shavings! These tools are used in many industries, from automotive to aerospace, to create everything from car parts to airplane components. They help turn big slabs of metal into sleek, useful shapes. Talk about a makeover!

| Industry | Application |

|---|---|

| Automotive | Parts manufacturing |

| Aerospace | Component creation |

| Construction | Tool production |

So, whenever you see a shiny metal part, remember that a lathe might have helped make it look so good!

Understanding Lathe Wiring Diagrams

Explanation of wiring diagrams and their importance. Key symbols and terminology used in wiring diagrams.Wiring diagrams are essential for understanding how a lathe works. They show how different parts connect. Without them, wiring can feel like trying to untangle spaghetti! Key symbols, like circuits and grounds, help us know what’s what. Here’s a quick peek at some important terms:

| Symbol | Meaning |

|---|---|

| 🔌 | Power Supply |

| ➿ | Ground Connection |

| 🔄 | Motor Control |

Understanding these symbols helps keep your lathe running smoothly. And remember, even wires want to be understood!

Step-by-Step Guide to Wiring a Metal Lathe

Tools and materials needed for wiring. Detailed wiring instructions with wiring diagram examples.Wiring a metal lathe sounds tough, but it’s easier than untangling your headphones! First, gather your tools and materials. You’ll need a screwdriver, wire cutters, electrical tape, and of course, the right wires. Check out the wiring diagram—it’s like a treasure map but with fewer pirates. Each wire connects something important, so pay attention! Here’s a simplified wiring table to guide you:

| Component | Connection |

|---|---|

| Power Supply | Connect to Main Switch |

| Main Switch | Connect to Motor |

| Motor | Connect to Control Board |

With the right tools and a clear diagram, you’re ready to wire your lathe. Don’t stress; if you make a mistake, just laugh it off and try again. Remember, every expert was once a beginner!

Troubleshooting Common Metal Lathe Wiring Issues

Identifying potential wiring problems. Solutions for common wiring faults and maintenance tips.Wiring issues can interrupt your metal lathe’s work. It’s important to spot problems early. Look for damaged wires, loose connections, or broken switches. These problems can cause your lathe to stop working. To fix these issues, try these tips:

- Check for frayed or cut wires.

- Tighten loose connections.

- Replace broken switches promptly.

Regular maintenance helps too! Clean the wires and connections often. This keeps your lathe running smoothly.

What are common signs of wiring problems?

Common signs include sparks, strange noises, and equipment not powering on. Always be on the lookout for these signs to prevent bigger problems.

Upgrading Your Metal Lathe’s Electrical System

Benefits of upgrading electrical components. Recommended upgrades and considerations before installation.Upgrading your metal lathe’s electrical system can make a big difference. It boosts performance and keeps you safe from shocking surprises! Some upgrades could include better wiring and a more reliable power supply. Before jumping in, think about compatibility and the tools you’ll need. Check out the table below for some recommended upgrades:

| Upgrade | Benefit |

|---|---|

| High-Quality Wiring | Increases durability and safety. |

| Digital Readouts | Makes precision easier. |

| Power Supply Upgrade | Enhances performance. |

Remember, a little planning can save you from a big mess—unless you enjoy having tiny metal squirrels in your workspace!

Safety Considerations When Wiring a Metal Lathe

Importance of safety protocols in wiring. Personal protective equipment (PPE) and safety practices.Wiring a metal lathe can be fun but it’s also dangerous. Always follow safety rules. Wearing Personal Protective Equipment (PPE) helps keep you safe. This includes gloves, goggles, and ear protection. Good safety practices are key, like:

- Turn off power before touching wires.

- Keep your workspace clean and organized.

- Ask for help if you’re unsure about something.

Practicing these simple steps makes wiring safer. Remember, a little caution goes a long way!

What PPE should I use when wiring a metal lathe?

You should wear gloves, goggles, and ear protection. These items help protect against cuts, debris, and loud noises. Always prioritize your safety!

Additional Resources and References

Recommended books, websites, and forums for further learning. Relevant videos and tutorials for visual learners.Learning more about metal lathes can be fun! Here are some great resources to help you. Check out books like “The Complete Guide to Metalworking” for detailed information. Websites like Instructables and the HSM (Home Shop Machinist) forum are also helpful. For hands-on learning, search for videos on YouTube. They show real-life metal lathe operations, making it easy to follow along.

- “The Complete Guide to Metalworking” – Book

- Instructables – Website

- HSM Forum – Online Community

- YouTube Tutorials – Video Guides

What are some helpful resources for learning about metal lathes?

Some helpful resources include books, websites, and video tutorials. These tools make it easy to learn and practice.

Conclusion

In summary, a lathe tutorial can help you understand metal lathe wiring diagrams clearly. Knowing how to wire a lathe is essential for safe machine operation. Keep practicing your skills, and don’t hesitate to explore more tutorials online. You can find videos or guides that make learning easy and fun. Start your metalworking journey today!FAQs

What Are The Essential Components In A Metal Lathe Wiring Diagram?A metal lathe wiring diagram shows how to connect electrical parts. The main parts include the motor, switches, and power supply. You also see wires that carry electricity. Each part needs to be connected correctly to work safely. This helps us use the lathe to shape metal easily.

How Do I Properly Wire A Metal Lathe For Optimal Performance And Safety?To wire a metal lathe safely, first, make sure the power is off. You need to connect the wires according to the manual. Use a proper circuit breaker to prevent overloads. Make sure all connections are tight and insulated. Finally, double-check everything before you turn it on.

What Are The Common Electrical Issues To Troubleshoot In A Metal Lathe Wiring Setup?When using a metal lathe, you might face some common electrical problems. First, check if the machine is plugged in and turned on. If it won’t start, the fuse or circuit breaker might be blown. Also, look for loose wires that could cause issues. Lastly, if the motor is overheating, it might need more cooling or repairs.

How Can I Modify An Existing Wiring Diagram To Accommodate A Variable Speed Drive For My Metal Lathe?To modify your wiring diagram for a variable speed drive (VSD), first, find the power supply lines. You will need to connect the VSD to these lines. Next, add wires to link the VSD to the motor of your metal lathe. Make sure to follow the instructions that come with the VSD. This will help your lathe run at different speeds!

What Safety Precautions Should Be Taken When Wiring And Operating A Metal Lathe?When using a metal lathe, we need to be careful. First, always wear safety goggles to protect your eyes. Make sure to keep long hair tied back and wear snug clothes. Keep your hands away from the moving parts. Lastly, remember to turn off the machine when you’re done.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components In A Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe wiring diagram shows how to connect electrical parts. The main parts include the motor, switches, and power supply. You also see wires that carry electricity. Each part needs to be connected correctly to work safely. This helps us use the lathe to shape metal easily.”}},{“@type”: “Question”,”name”: “How Do I Properly Wire A Metal Lathe For Optimal Performance And Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe safely, first, make sure the power is off. You need to connect the wires according to the manual. Use a proper circuit breaker to prevent overloads. Make sure all connections are tight and insulated. Finally, double-check everything before you turn it on.”}},{“@type”: “Question”,”name”: “What Are The Common Electrical Issues To Troubleshoot In A Metal Lathe Wiring Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you might face some common electrical problems. First, check if the machine is plugged in and turned on. If it won’t start, the fuse or circuit breaker might be blown. Also, look for loose wires that could cause issues. Lastly, if the motor is overheating, it might need more cooling or repairs.”}},{“@type”: “Question”,”name”: “How Can I Modify An Existing Wiring Diagram To Accommodate A Variable Speed Drive For My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To modify your wiring diagram for a variable speed drive (VSD), first, find the power supply lines. You will need to connect the VSD to these lines. Next, add wires to link the VSD to the motor of your metal lathe. Make sure to follow the instructions that come with the VSD. This will help your lathe run at different speeds!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring And Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, we need to be careful. First, always wear safety goggles to protect your eyes. Make sure to keep long hair tied back and wear snug clothes. Keep your hands away from the moving parts. Lastly, remember to turn off the machine when you’re done.”}}]}