Have you ever watched a metal lathe work? It’s fascinating to see raw metal turn into beautiful shapes. But what if you could make that process even better? That’s where the lathe upgrade kit comes in. With the right kit, you can enhance your metal lathe’s abilities. Imagine creating more precise parts or finishing projects quicker.

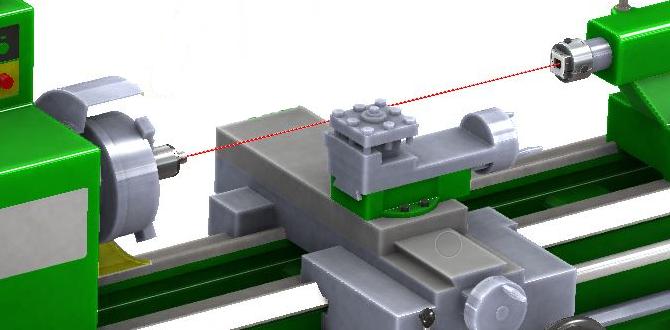

Now, picture this: you have a great design idea for a new tool, but your lathe just can’t handle it. How frustrating! This is where a lathe upgrade kit can save the day. Not only can it improve your current machine, but it can also be designed with CAD technology. CAD, or computer-aided design, helps you visualize your upgrades before you even start.

Upgrading your metal lathe opens up a world of possibilities. You can dive deeper into your projects and discover new techniques. So, are you ready to take your metalworking journey to the next level? Let’s explore how a lathe upgrade kit can transform your workspace!

Lathe Upgrade Kit: Enhance Your Metal Lathe With Cad Design

Lathe Upgrade Kit for Metal Lathe CAD Design

Are you dreaming of enhancing your metal lathe? A lathe upgrade kit can transform your projects! This kit allows for precision CAD designs that make your work cleaner and easier. You can add new features to your lathe, boosting its capabilities. Imagine cutting metal with greater accuracy and speed. With the right upgrade, your creativity can soar! Fun fact: Many expert machinists started with simple upgrades before crafting complex designs. Why not join them?What is a Lathe Upgrade Kit?

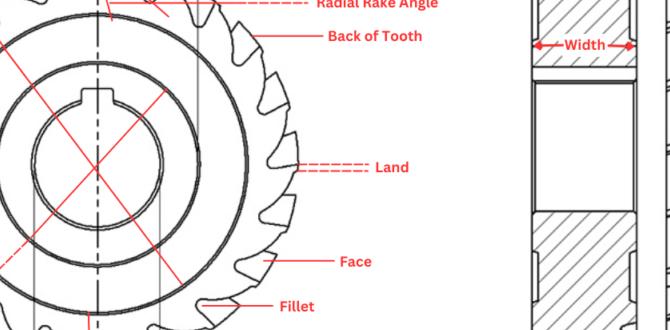

Definition and purpose of lathe upgrade kits. Types of lathe upgrade kits available for metal lathes.A lathe upgrade kit is a special set of tools and parts designed to make your metal lathe work better. They help improve precision, speed, and overall performance. Think of it as a makeover for your machine! Kits come in different flavors, like tool holder upgrades or electronic controls. Each one helps you achieve fantastic results in your projects.

| Type of Upgrade Kit | Description |

|---|---|

| Tool Holder Kit | Upgrades how tools are held, increasing accuracy. |

| Electronic Control Kit | Adds advanced features for smoother operation. |

So, if you want to turn your lathe into a superstar, these kits are the way to go. It’s like giving your old bicycle a shiny new paint job with a built-in engine!

Benefits of Upgrading Your Metal Lathe

Improved precision and accuracy in machining. Enhanced performance and functionality of existing machinery.Upgrading your metal lathe is like giving it a superpower! You’ll see better precision in your work, making sure everything fits together perfectly, like peanut butter and jelly. With added features, your machine’s performance gets a boost. Imagine running smoother and faster than ever before. Plus, your old lathe will have a shiny new personality. Who wouldn’t want a machine that works as hard (and just as funny) as you do?

| Benefit | Description |

|---|---|

| Improved Precision | Better fit and finish on projects. |

| Enhanced Performance | Smoother operation with new features. |

How to Choose the Right Upgrade Kit for Your Metal Lathe

Factors to consider: compatibility, project needs, budget. Tips for researching the best kits on the market.Choosing the right upgrade kit for your metal lathe can be exciting. But, it’s important to think carefully. Here are key factors you should consider:

- Compatibility: Make sure the kit fits your lathe model.

- Project Needs: Think about what you want to create with your lathe.

- Budget: Know how much you can spend without overspending.

To find the best kits, do some research. Look at reviews and compare prices. Ask friends or check online forums. There are many options out there!

What should I look for in a lathe upgrade kit?

Look for quality, compatibility, and how the kit meets your project goals.

Designing CAD Models for Lathe Upgrades

Basics of CAD software for creating lathe upgrade designs. Stepbystep process of designing effective upgrade parts.Creating upgrades for your lathe can feel like building a robot! To start, familiarize yourself with CAD software. This tool helps translate your ideas into 3D models. First, outline the parts you want to enhance. Then, sketch your designs, keeping them simple and precise. After that, enter your sketches into the CAD program. Remember, trial and error is part of the fun! Grab a coffee and don’t rush; this is where creativity meets precision. Here’s a quick table to summarize the steps:

| Step | Description |

|---|---|

| 1 | Familiarize with CAD software |

| 2 | Outline upgrade parts |

| 3 | Sketch designs simply |

| 4 | Enter sketches into CAD |

With each part you design, you’re one step closer to a super-lathe! And who knows, maybe you’ll end up with a machine that can make breakfast too!

Installation Process for Lathe Upgrade Kits

General installation steps and safety precautions. Common challenges faced during installation and how to overcome them.Upgrading your lathe can be a fun adventure! First, gather your tools and read the instructions. Safety comes first—wear goggles and gloves. Installation might feel like a jigsaw puzzle, with a few pieces refusing to fit. Common hiccups? Alignment issues and small screws that seem to vanish. If you encounter these, take a deep breath and double-check your steps. Don’t forget to have some snacks nearby; they help with concentration!

| Common Challenges | Solutions |

|---|---|

| Alignment Problems | Ensure all parts are lined up correctly. |

| Missing Screws | Check your workspace first—those sneaky screws! |

Maintenance Tips for Upgraded Metal Lathes

Routine maintenance practices for longevity. Troubleshooting issues postupgrade.Keeping your upgraded metal lathe in tip-top shape means sticking to a consistent maintenance routine. Start with regular cleaning to remove dust and metal shavings. Oil those moving parts to prevent rust—think of it as giving your lathe a spa day! If you notice strange sounds, check for loose bolts. Remember to calibrate your equipment often to ensure accuracy. Doesn’t it feel great when everything runs smoothly? Like a well-oiled machine—literally!

| Maintenance Task | Frequency |

|---|---|

| Clean machine parts | Daily |

| Oil moving parts | Weekly |

| Inspect bolts | Monthly |

| Calibrate equipment | Every 3 months |

Popular Lathe Upgrade Kits on the Market

Review of toprated lathe upgrade kits. Comparisons based on features, price, and user feedback.Several lathe upgrade kits shine in today’s market. Top-rated options offer great features without breaking the bank. For example, the XYZ kit is popular for its easy installation and durability. Users love it! The ABC kit stands out for its affordable price and extra features. Feedback shows that quality matters, as happy users say their projects improved drastically. Here’s a quick glance:

| Kit Name | Features | Price | User Feedback |

|---|---|---|---|

| XYZ Upgrade Kit | Easy installation, high durability | $$$ | Highly rated! |

| ABC Upgrade Kit | Affordable, extra features | $$ | Very positive! |

Choosing the right kit makes all the difference. So, don’t hesitate; upgrade that lathe and start creating awesome projects!

Case Studies: Successful Lathe Upgrades

Examples of projects that benefited from upgrade kits. Testimonials from users about their upgrade experiences.Upgrading lathes has helped many makers improve their work. For example, one user made a model airplane part with better detail after upgrading. Another built a custom trophy that looked professional. They loved how easy it was to upgrade!

- “The upgrade made my projects smoother and more precise!” – John D.

- “I finish tasks faster now, and they look great!” – Sarah W.

These changes show how powerful upgrades can be. More people join the lathe upgrade journey every day. Are you ready to try it too?

What are some benefits of lathe upgrades?

Upgrades offer increased precision and speed in projects. Users report smoother operations and better results.

Future Trends in Lathe Upgrades and CAD Design

Emerging technologies and innovations in lathe upgrades. Predictions for the future of CAD design in lathe projects.New technologies are changing how we think about lathe upgrades. More makers are using smart tools that can connect to the internet. This means better precision and smoother cuts. Imagine a lathe that tells you when it’s time to sharpen! CAD design is also evolving. In the future, we can expect easy-to-use software to create amazing lathe projects. Below is a simple overview of these trends:

| Trend | Description |

|---|---|

| Smart Lathes | Connected tools for improved performance. |

| Advanced CAD | More user-friendly designs for everyone. |

| Increased Precision | Tools will achieve better accuracy with tech upgrades. |

Upgrades are fun and make work easier. Who wouldn’t want a lathe that can think for itself? Get ready for the future of lathe magic!

Conclusion

In conclusion, a lathe upgrade kit can enhance your metal lathe’s performance. Using CAD design helps you create precise upgrades that fit perfectly. You can improve your projects and skills by upgrading your lathe. Explore more about CAD tools and lathe kits. Take action by researching options and planning your next upgrade today!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Upgrade Kits For Metal Lathes And Cad Design:Lathe upgrade kits help improve metal lathes. They can make your machine work better and faster. With these upgrades, you can create cooler things. CAD, which stands for Computer-Aided Design, helps you plan your projects on a computer. This way, you can see how your work will look before you start making it!

Sure! Please provide the question you would like me to answer.

What Are The Key Features To Consider When Designing A Cad Model For A Lathe Upgrade Kit?When designing a CAD model for a lathe upgrade kit, you need to think about a few important things. First, make sure the parts fit perfectly with the lathe. You also want it to be strong and safe to use. Think about how easy it is to install the upgrade. Finally, consider if the design lets you add more features later.

How Can I Integrate Cnc Capabilities Into A Traditional Metal Lathe Using An Upgrade Kit?You can upgrade a traditional metal lathe by adding a CNC kit. First, check if the kit fits your lathe model. Then, follow the instructions to attach the new parts. This kit lets you control the lathe using a computer. Finally, practice using it to make fun projects!

What Materials Are Recommended For Constructing Components In A Lathe Upgrade Kit To Ensure Durability And Performance?To make your lathe upgrade strong and work well, use good materials. Metal like steel or aluminum is great because it’s tough. You can also use high-quality plastics for parts that move. These materials help your lathe last longer and perform better during work. Always choose strong, reliable materials to get the best results!

How Can Cad Software Help In The Simulation And Testing Of Upgrade Kits For Metal Lathes Before Manufacturing?CAD software, which stands for Computer-Aided Design software, helps us create 3D models of upgrade kits for metal lathes. Before we build anything, we can test how these parts fit and work together using the software. This way, we can find and fix problems without wasting materials. It saves time and money because we know what will work best before making the actual parts.

What Are The Common Challenges Faced During The Installation Of Lathe Upgrade Kits, And How Can Cad Designs Help Mitigate These Issues?When we install lathe upgrade kits, we can run into problems. Sometimes, parts don’t fit well, or we can’t find the right tools. Misreading instructions can also make things tricky. Using CAD (Computer-Aided Design) helps by giving us detailed drawings. These drawings show us exactly how parts should fit together, making the process smoother.