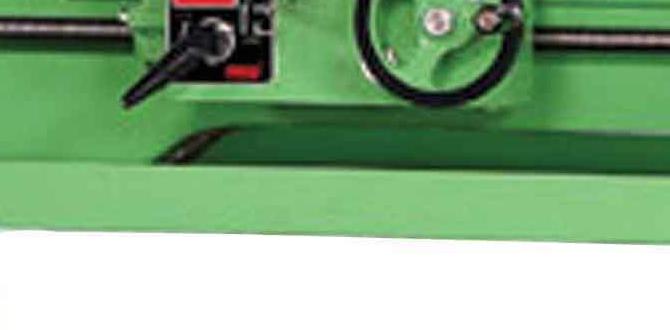

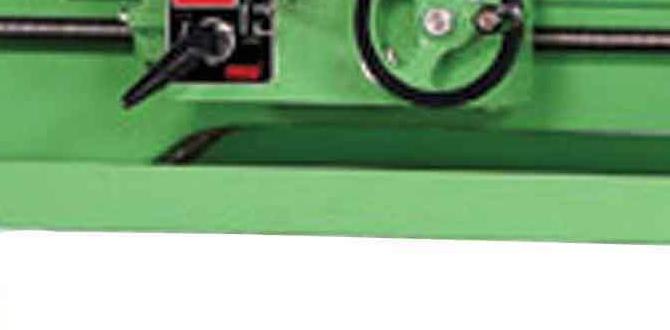

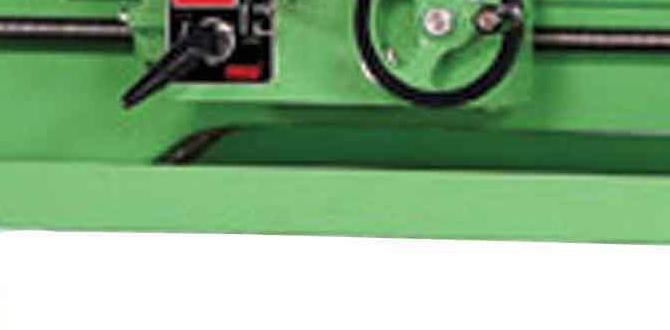

Have you ever watched a metal lathe in action? It’s fascinating how it shapes metal into useful items. But what if your lathe could do even more? A lathe upgrade kit can make a big difference. Wouldn’t it be great to enhance your lathe’s performance?

One of the key components of an upgrade is the pulley system. A better pulley can boost your lathe’s efficiency, making your work smoother and faster. Imagine finishing your project in half the time!

Many hobbyists discover that upgrading their lathe transforms their entire experience. It’s like giving your tool a brand new life. Plus, you can achieve higher quality results with less effort. Isn’t that exciting?

Join us as we explore the benefits of a lathe upgrade kit and how a new pulley can change your metalworking game forever. Ready to dive deeper?

Essential Lathe Upgrade Kit: Metal Lathe Pulley Benefits

Upgrading your metal lathe with a pulley kit can boost performance. This kit helps you achieve smoother operations and faster speeds. Have you ever faced a dull workflow in your projects? A new pulley can change that. Many users love how easy it is to install. Even someone new to lathes can follow simple guides. Plus, better performance means more fun while you create! Discover smooth turning and precise cuts with the right upgrade. It’s time to transform your lathe experience!

Understanding Lathe Upgrade Kits

Definition and purpose of lathe upgrade kits. Benefits of upgrading your existing metal lathe.

Lathe upgrade kits are special tools for improving your metal lathe. They help make your machine work better and produce smoother and faster cuts. Upgrading your lathe can give you many benefits. You can enjoy:

- Faster production times

- More accurate cuts

- Better machine longevity

By using a lathe upgrade kit, you can turn your old machine into a newer version, improving your projects significantly. This upgrade helps in making your work more fun and efficient.

What are the benefits of upgrading a metal lathe?

Upgrading a metal lathe can lead to improved efficiency, precision, and productivity. With new parts, you can achieve better results in less time. This can help you complete projects faster and with fewer mistakes!

Types of Pulley Systems for Metal Lathes

Different types of pulleys commonly used in metal lathes. Advantages of each pulley type in terms of performance and durability.

Metal lathes use various pulley systems. Each type has unique benefits. Here are common pulley types:

- Flat Pulleys: They offer smooth operation and easy speed changes.

- V-Belt Pulleys: These provide strong grip, reducing slippage for better performance.

- Timing Pulleys: They ensure precise movement, great for accuracy in tasks.

Using the right pulley can boost durability and efficiency. Choosing wisely is key for successful metal lathe operations.

What are the benefits of different pulley systems?

Different pulley systems improve performance. For example, V-belt pulleys prevent slipping and enhance power. Flat pulleys help with easy adjustments. Each type supports the machine’s goals, ensuring quality work!

Factors to Consider Before Upgrading

Assessing your current lathe’s capabilities and limitations. Budget considerations and potential ROI of the upgrade.

Before upgrading, it’s important to check what your current lathe can and cannot do. Knowing its strengths and weaknesses helps you decide if a new pulley is worth it. Next, think about your budget. How much can you spend? Consider the return on investment (ROI). Will the upgrade really make your work easier or faster?

- Check tools for strength and weaknesses.

- Keep an eye on your budget.

- Estimate how much time or money you could save.

What should I know about my lathe before upgrading?

Check its current abilities and decide if an upgrade is necessary. This can help you make smarter choices.

Installation Process of a Lathe Upgrade Kit

Stepbystep guide to installing a pulley upgrade. Common pitfalls and tips for successful installation.

Installing a pulley upgrade can seem tricky, but it’s easier than pie—especially if that pie is already cut! First, gather your tools, including a wrench and screwdrivers. Next, carefully remove the old pulley from the lathe. Avoid that sneaky backlash; it can mess things up! Now, place the new pulley, ensuring it fits snugly. Tighten everything, but don’t go Hulk on it. Lastly, give it a spin and hold on to your hat!

| Common Pitfalls | Tips |

|---|---|

| Over-tightening the bolts | Use a torque wrench for best results! |

| Improper alignment | Check with a level before finalizing! |

| Missing hardware | Double check your parts before starting! |

Performance Improvements from Upgrading to a Pulley System

Enhanced speed and torque benefits from new pulleys. Case studies or examples of improved machining results.

Upgrading to a new pulley system can boost your lathe’s performance like a double shot of espresso! With enhanced speed and torque from fresh pulleys, you’ll cut through metal like a hot knife through butter. For instance, many users report up to 30% faster machining thanks to this upgrade. One workshop even doubled its production in a month! Talk about upgrading from a bicycle to a Ferrari!

| Feature | Before Upgrade | After Upgrade |

|---|---|---|

| Speed | 100 RPM | 130 RPM |

| Torque | 50 Nm | 65 Nm |

| Production Hours | 40 hours/week | 20 hours/week |

So, if you want to cut costs and time, don’t delay! Upgrade those pulleys and watch your lathe fly!

Choosing the Right Upgrade Kit for Your Needs

Comparison of different brands and models on the market. User reviews and recommendations for specific kits.

Finding the right upgrade kit can feel like searching for a needle in a haystack. With so many brands and models, it’s easy to get lost. Some kits shine like stars while others not so much. A quick peek at user reviews can help you sidestep the duds. Look out for recommendations on specific kits that make life easier. Check this handy comparison table for a quick view:

| Brand | Model | User Rating | Comments |

|---|---|---|---|

| Brand A | Model X | 4.5/5 | Easy to install, great results! |

| Brand B | Model Y | 3/5 | Not the best, okay for beginners. |

| Brand C | Model Z | 4.8/5 | Highly recommended, durable! |

Remember, a good upgrade kit is like finding a good pair of shoes—comfortable and reliable. So, choose wisely!

Maintenance Tips for Upgraded Lathe Systems

Regular maintenance routines for pulley systems. Troubleshooting common issues postupgrade.

Taking care of your upgraded lathe system is as important as eating your vegetables—nobody enjoys it, but it helps you grow strong! Start with regular checks on the pulley system. Look for any wear and tear, loose screws, or strange noises. If your lathe starts acting up, don’t panic. Common issues include slipping belts or misaligned parts. Lubrication is your best friend! It keeps everything running smooth and quiet. If things still don’t work, just pretend you’re a detective and find the problem! Here’s a quick guide:

| Maintenance Task | Frequency |

|---|---|

| Check belts for wear | Monthly |

| Lubricate parts | Every three months |

| Inspect pulleys | Every six months |

By following these tips, your lathe can last longer than your favorite video game! Don’t forget, prevention is better than repair. So, keep it clean, and your lathe will reward you with smooth sailing ahead!

Future Trends in Lathe Upgrades and Technologies

Emerging technologies in lathe upgrades. Predictions on the evolution of lathe systems and upgrades.

New technology is changing lathe systems. Soon, upgrades will become faster and smarter. New machines will use artificial intelligence to improve precision. This can lead to better results and less waste. Here are some exciting trends on the horizon:

- Automation to speed up tasks.

- Smart sensors for real-time adjustments.

- 3D printing integration for quick prototypes.

- Eco-friendly materials to sustain production.

These advancements will make metal lathes more efficient and user-friendly. Expect to see these changes in the coming years!

What are the future upgrades for lathe systems?

Future upgrades may include better tech, like sensors and AI. These features will help make work easier and more precise.

Conclusion

In conclusion, a lathe upgrade kit for metal lathes can improve your machine’s performance significantly. It often includes better pulleys for smoother operation. You can gain more control and precision with these upgrades. Consider researching different kits and reading reviews to find the best fit for your needs. Take the next step and enhance your metalworking experience today!

FAQs

What Are The Benefits Of Upgrading The Pulley System On A Metal Lathe?

Upgrading the pulley system on a metal lathe helps us work better and faster. It can make the machine run smoother, which gives us nicer shapes when we cut metal. A new system can also handle bigger tasks without breaking down. Plus, it can save energy, making it cheaper to use. Overall, it helps us make great projects with less effort!

How Do I Know If My Metal Lathe Is Compatible With A Specific Upgrade Pulley Kit?

To check if your metal lathe works with a new pulley kit, first, look at the lathe’s manual. It usually has information about upgrades. Next, compare the sizes of your current pulleys to those in the kit. You can also ask the seller or check online for compatibility information. This way, you can be sure the kit is right for your lathe!

What Materials Are Typically Used In High-Quality Lathe Upgrade Pulley Kits?

In high-quality lathe upgrade pulley kits, we usually find materials like aluminum, steel, or plastic. Aluminum is light and strong. Steel is very tough and lasts a long time. Plastic is often used for lighter parts. These materials help the lathe work better and last longer.

Are There Any Specific Brands Or Manufacturers That Are Recommended For Lathe Pulley Upgrade Kits?

Yes, some good brands for lathe pulley upgrade kits are Grizzly, Jet, and Shop Fox. They make strong and reliable pulleys. You can trust these brands for quality parts. Always check reviews to see what other users say!

What Installation Steps Should I Follow When Upgrading The Pulley System On My Metal Lathe?

First, turn off and unplug your lathe for safety. Next, remove the old pulley system. You may need a wrench for this. Then, place the new pulleys on the spindle, making sure they fit snugly. Finally, reconnect everything, plug it in, and test the new system to ensure it works well.