Have you ever tried to align the tailstock of your metal lathe? It can be tricky! A small misalignment can lead to big problems in your projects. You might waste time and materials if everything isn’t just right.

Fortunately, a lathe upgrade kit can make this task easier. These kits can help you get your lathe working perfectly. Are you curious about how a simple upgrade can change your woodworking or metalworking experience?

In this article, we will explore how a lathe upgrade kit improves tailstock alignment. We’ll dive into why it matters and what you need to know. Get ready to unlock better results and smoother operation!

Lathe Upgrade Kit: Metal Lathe Tailstock Alignment Tips

A lathe upgrade kit can transform your metal lathe experience. Proper tailstock alignment makes a big difference in your projects. It improves accuracy and helps you work with precision. Did you know misalignment can lead to poor quality cuts? Using an upgrade kit, you can easily fix this issue. With simple adjustments, your lathe becomes more reliable. This upgrade not only boosts performance but also enhances your skills. Isn’t it exciting to see your hard work pay off with better results?

Understanding Lathe Upgrade Kits

Definition and purpose of lathe upgrade kits. Benefits of upgrading your metal lathe.

Lathe upgrade kits are special tools that improve metal lathes. Their goal is to make the lathe work better and more accurately. Upgrading your lathe offers many benefits, such as:

- Improved Precision: Better cuts and shapes.

- Increased Speed: Faster work means more projects done.

- Enhanced Features: New tools provide advanced functions.

- Longer Lifespan: Stronger parts can last longer.

These upgrades help hobbyists and professionals alike. They can turn a good lathe into a great one!

What should I consider when upgrading my lathe?

Focus on compatibility, cost, and desired improvements. Choose kits that fit your lathe model for the best results.

The Importance of Tailstock Alignment

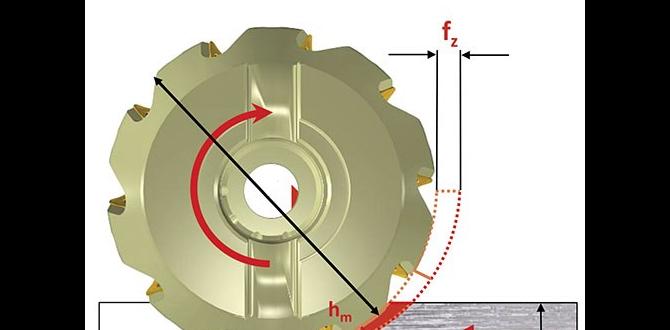

How tailstock alignment affects machining accuracy. Common issues caused by misalignment.

Tailstock alignment is very important for getting good results from your metal lathe. If the tailstock is not properly aligned, it can lead to mistakes during machining. This can make parts come out incorrectly shaped or not fit as they should. Common issues from misalignment include:

- Uneven cuts

- Parting problems

- Excess wear and tear

Being careful with tailstock alignment helps you achieve precise and accurate work every time. That’s how you make high-quality parts!

How does tailstock alignment affect machining accuracy?

Proper tailstock alignment ensures that parts are made correctly and fit together perfectly. Misalignment can cause serious issues, leading to wasted time and materials. Always check your lathe setup!

Components of a Lathe Upgrade Kit

Key components included in most upgrade kits. Quality and materials to look for in upgrade components.

Upgrading your lathe can be fun and make it work better! Most kits include key parts like alignment bars, tailstock clamps, and tool holders. These help your machine stay precise and straight, just like a well-behaved dog! Quality matters too. Look for durable materials like steel or aluminum. They can handle tough jobs and will last longer, saving you money in the long run. A sturdy lathe is like a strong superhero, ready to tackle any task!

| Component | What It Does | Best Material |

|---|---|---|

| Alignment Bars | Helps with accuracy | Steel |

| Tailstock Clamps | Stabilizes the tailstock | Aluminum |

| Tool Holders | Securely hold tools | Steel or High-Grade Plastic |

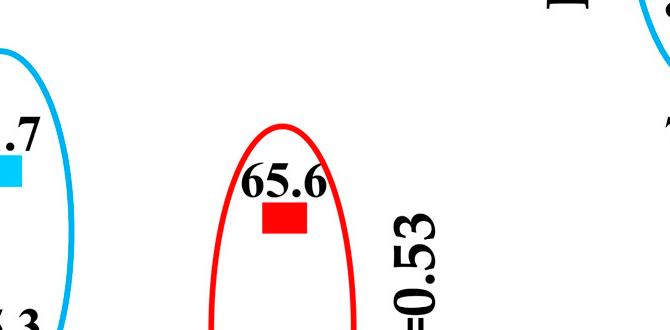

Steps to Align the Tailstock

Tools required for tailstock alignment. Detailed stepbystep alignment process.

To get that tailstock in line, you’ll need a few handy tools. Grab a dial indicator, a wrench, and some clean cloths. Now, let’s tackle the alignment process step by step. It’s easier than putting together a toy you got for your birthday!

| Step | Action |

|---|---|

| 1 | Check the tailstock’s position on the bed. |

| 2 | Use the dial indicator at the spindle. |

| 3 | Adjust the tailstock using your wrench. |

| 4 | Recheck the alignment with the dial indicator. |

Repeat until it’s just right! Once aligned, it’ll take your projects from “oops” to “wow!” in no time.

Choosing the Right Upgrade Kit for Your Needs

Factors to consider when selecting an upgrade kit. Comparing popular brands and their features.

Upgrading your lathe is a big decision. You need to choose the right kit for your needs. Start by thinking about these factors:

- Compatibility with your lathe model.

- Quality of materials used.

- Ease of installation.

Different brands offer various features. Some kits might include better tailstock alignment options. Check reviews to see what others say. Popular brands often stand out for their reliability and performance. Don’t rush; a good upgrade can make your projects easier and more fun!

What should I consider before buying a lathe upgrade kit?

Consider the compatibility, materials, and installation ease when buying a lathe upgrade kit.

Key considerations:

- Check if the kit fits your lathe type.

- Look for durable parts.

- Ensure clear instructions are included.

DIY vs. Professional Upgrades

Pros and cons of DIY tailstock alignment. When to seek professional assistance.

Upgrading your lathe can be like deciding between pizza and sushi; both have their perks! DIY tailstock alignment is fun and costs less. You can brag about doing it yourself. However, if anything goes wrong, you may face a real pickle. Professionals have tools and skills to get it right. It might cost more, but your lathe will thank you. Here’s a quick look:

| DIY Tailstock Alignment | Professional Assistance |

|---|---|

| Pros: Save money, learn skills, and be a hero in your workshop! | Pros: Expert results, save time, peace of mind. |

| Cons: Risk of errors, requires time. | Cons: Can be expensive. |

In short, if you’re feeling brave, give it a shot! But if you prefer smooth sailing, don’t hesitate to call the pros.

Maintenance Tips for Longevity

Best practices for maintaining upgraded components. How to regularly check and ensure tailstock alignment.

To keep your upgraded parts working well, you need to treat them nicely! Regular cleaning is key. Use a soft cloth to wipe away dust and keep things shiny. Check the tailstock alignment often. It’s not just a fancy term; it helps your lathe make smooth cuts. If it is off, just adjust it until it’s right. Your lathe will thank you by lasting longer! Here’s a quick table to follow:

| Task | Frequency | Tip |

|---|---|---|

| Clean components | Weekly | Use a soft cloth. |

| Check tailstock alignment | Monthly | Make small adjustments as needed. |

| Lubricate moving parts | Every few months | Don’t drown them; a little goes a long way! |

Follow these tips, and your lathe will be the star of the workshop! Remember, a happy lathe equals a happy user!

Frequently Asked Questions

Common queries regarding lathe upgrade kits and tailstock alignment. Expert answers and troubleshooting tips.

Many people wonder about lathe upgrade kits and tailstock alignment. Common questions include: How do I know if my tailstock is aligned? The answer is simple: use a test bar! If it’s off, it’s time to adjust. Another popular query is, “What if my upgrades don’t fit?” Well, check your measurements twice—like you would when baking a cake! Lastly, if you encounter issues, remember to grab a manual or watch a video. Help is often a click away! Here’s a quick table with some FAQs:

| Question | Expert Answer |

|---|---|

| How do I align my tailstock? | Use a test bar for accurate results. |

| What if the upgrade doesn’t fit? | Double-check your measurements! |

| Where can I find help? | Check manuals or instructional videos! |

Customer Reviews and Experiences

Summary of user experiences with various upgrade kits. Impact of upgrades on machining performance.

Many users share their thoughts on lathe upgrade kits for tailstock alignment. Most find it easy to install and effective. The best part? Machining gets smoother, making projects more enjoyable. One user joked that the tailstock used to play hide and seek, but not anymore! Check out this quick summary:

| User Experience | Performance Effects |

|---|---|

| Easy Installation | Improved Accuracy |

| Smoother Operations | Better Finish Quality |

| Cost-Effective | Less Material Waste |

Overall, happy customers highlight the value of these upgrades, which make machining a breeze!

Conclusion

In conclusion, a lathe upgrade kit helps improve your metal lathe’s tailstock alignment. Proper alignment ensures accuracy and better project results. You can boost your skills by upgrading your equipment. Remember to read product reviews and consult guides for the best options. Try adjusting your tailstock today, and see the difference it makes in your work!

FAQs

What Are The Key Components Of A Lathe Upgrade Kit That Can Improve Tailstock Alignment?

A lathe upgrade kit can help your machine work better. Key parts include a new tailstock, special alignment tools, and adjustable screws. These parts help make sure everything lines up straight. When things are straight, it makes it easier to cut materials evenly. You’ll get better results when you use these upgraded parts.

How Can Improper Tailstock Alignment Affect The Accuracy Of Machining Operations On A Metal Lathe?

Improper tailstock alignment can cause problems when we use a metal lathe. If it’s not lined up right, the tool might not cut smoothly. This can make parts uneven or too big. You might end up with pieces that don’t fit together well. So, good alignment helps us make better and more accurate parts.

What Are Some Common Methods For Aligning The Tailstock On A Metal Lathe After Installing An Upgrade Kit?

To align the tailstock on a metal lathe, you can use a few simple methods. First, check the alignment with a test bar. This bar is a straight piece of metal that helps you see if the tailstock is straight. You can adjust it until it lines up perfectly with the spindle center. Another method is to use feeler gauges, which are thin cards that show small gaps, to check and adjust the position. Finally, you can also check by turning a small piece and seeing if it cuts evenly along the length.

Are There Specific Upgrade Kits Designed To Enhance The Tailstock Features Of Particular Metal Lathe Brands Or Models?

Yes, some metal lathe brands make special upgrade kits just for their machines. These kits can add cool features to the tailstock. You can find kits that help with things like better accuracy or easier use. Check your lathe’s brand to see what upgrades are available. It’s a fun way to improve your machine!

What Tools Or Jigs Are Recommended For Checking And Adjusting The Tailstock Alignment On A Metal Lathe?

To check and adjust the tailstock on a metal lathe, you can use a few simple tools. A test bar is great for this task. You can also use a dial indicator, which helps you see small changes accurately. A tailstock alignment jig is another helpful tool. These make it easier to ensure everything is straight and works well.