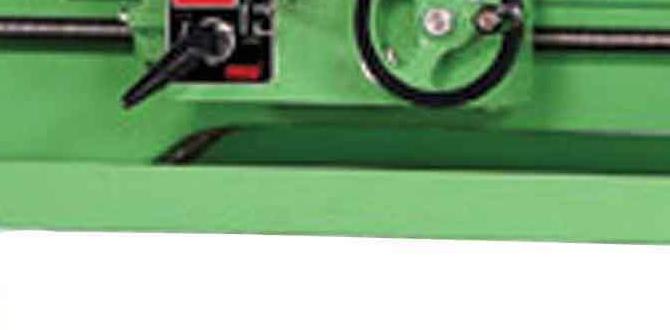

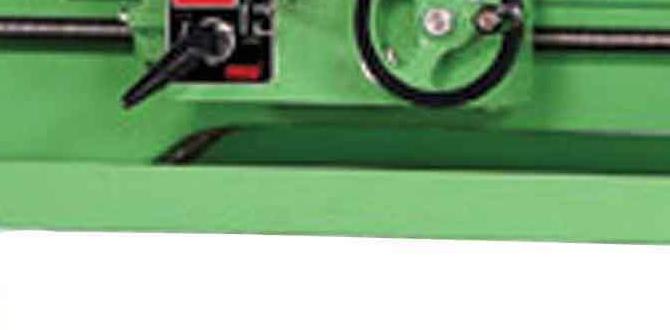

Have you ever noticed how a small upgrade can transform a machine? It’s true! Just look at metal lathes. These tools are amazing for shaping metal. But what if I told you there’s a simple way to make your lathe even better? Enter the lathe upgrade kit, specifically designed for metal lathes.

Imagine struggling with threading. You try to get it right, but your threading dial just isn’t helping. Frustrating, isn’t it? Now, picture adding a threading dial that works smoothly with your lathe. Suddenly, that project you’ve dreamed of creating becomes achievable.

Did you know that many hobbyists ignore upgrading their tools? Yet, a lathe upgrade kit can save time and boost precision. Think about all those times you wished for better results—this is your chance to get them. In this article, we will explore the benefits of using a lathe upgrade kit with a threading dial. Get ready to enhance your metalworking experience!

Lathe Upgrade Kit: Enhance Your Metal Lathe Threading Dial

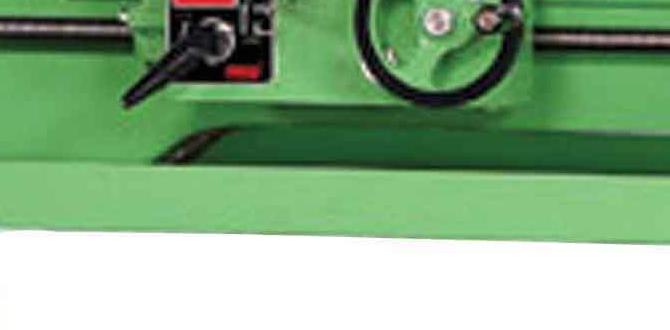

Lathe Upgrade Kit Metal Lathe Threading Dial

Upgrading your metal lathe with a threading dial can transform your projects. This handy tool helps you set precise thread measurements. Imagine finishing your projects faster and more accurately! A lathe upgrade kit contains all the parts needed for easy installation. You’ll learn how to enhance your tool’s capabilities without spending much. It’s a smart way to boost your metalworking skills and impress your friends with your craftsmanship. Why not explore the benefits today?Understanding Lathe Upgrade Kits

Definition and purpose of lathe upgrade kits. Importance of improving threading capabilities in metal lathes.Lathe upgrade kits help make metal lathes work better. They add new features to machines. In particular, a threading dial is important. It helps operators cut threads accurately. This upgrade improves the overall quality of work. With better threading, projects will be neater and more precise. Plus, it saves time in the workshop.

Why are lathe upgrade kits important?

They boost performance and precision in metal lathes. This means you can complete projects faster and with better results. Investing in these kits can make your work easier and more efficient.

Key Benefits:

- Improved accuracy for cutting threads.

- Faster project completion.

- Increased overall machine performance.

Choosing the Right Upgrade Kit for Your Metal Lathe

Factors to consider when selecting an upgrade kit. Compatibility with different types of metal lathes.Upgrading your metal lathe can feel like choosing the right toppings for a pizza. You want the best, but there are so many options! First, check compatibility with your lathe model. Not all kits fit all machines; size matters! Next, consider the features. A good upgrade kit should make your work easier, like adding extra cheese to that pizza. Oh, and don’t forget your budget! Compare prices to get a deal. Finally, read reviews. You want the best pizza in town, not the one that burns down your kitchen!

| Factors | Considerations |

|---|---|

| Compatibility | Match the kit with your lathe model |

| Features | Ease of use and efficiency |

| Budget | Compare prices for the best deal |

| Reviews | Rate others’ experiences with the kit |

Step-by-Step Installation Guide for Threading Dials

Detailed installation process for upgrading to a threading dial. Tips for ensuring accurate installation and alignment.Start by gathering your tools and the new threading dial. Safety first! Turn off your lathe. Remove the existing dial carefully. Align the new threading dial accurately with the machine. Secure it tightly. Check the alignment again. This ensures smooth operation. Here are some tips:

- Double-check measurements before securing.

- Use a level to confirm it’s straight.

- Test the dial before finishing up.

Take your time, and enjoy the upgrade process!

How can I make sure the threading dial is installed correctly?

Use a level and measure twice to ensure proper alignment. Testing the dial after installation helps catch any issues early.

Common Issues and Troubleshooting

Identifying common problems faced during installation or use. Solutions and tips for troubleshooting threading dial issues.During installation or use, some common problems may occur with your lathe upgrade kit. Here are some issues and how to solve them:

- Threading dial won’t move. Check if it’s connected properly.

- Inaccurate measurements. Calibrate the machine for better results.

- Noise during operation. Inspect for loose parts and tighten them.

- Slipping gears. Lubricate the gears to improve function.

Keeping your lathe in shape can save time and effort. Regular maintenance is the key to smooth operation.

What should I do if my threading dial is stuck?

Check all connections and clean the dial. If it’s still stuck, a light lubricant may help.

Why is my lathe making strange noises?

Strange noises often mean there’s a loose part. Tighten screws and lubricate moving parts.

Being aware of these issues can enhance your experience with the lathe upgrade kit. Troubleshoot quickly to keep your work on track!

Performance Benefits of Upgrading Your Lathe

Improvement in precision and efficiency with upgraded threading dials. Case studies or testimonials from users who upgraded their lathes.Upgrading your lathe with a new threading dial can make a big difference. You’ll see better precision in your work. Many users report they save time and effort. Faster results lead to more projects completed. Testimonials show satisfied customers feel more confident in their skills. Their stories inspire new users. Here are a few benefits of upgrading:

- Improved accuracy: Enhanced threading dials help in cutting more exact threads.

- Increased efficiency: Users finish tasks quicker and with less hassle.

- Greater satisfaction: Craftsmen enjoy their work more with easier setups.

How do lathe upgrades affect performance?

Upgrading your lathe improves its overall performance by providing precise measurements and smoother operation.Maintenance Tips for Upgraded Lathes

Recommended maintenance practices for optimal performance. Frequency and best methods for checking threading dial accuracy.Keeping your lathe in top shape is like taking care of a pet. Feed it with oil and give it a little love every now and then! Regular cleaning can help your machine run smoothly. Aim for a deep clean every month, and dust off the threading dial weekly. Always check its accuracy, especially before big projects. A simple way is to measure against a known standard. Remember, a happy lathe means happy projects!

| Maintenance Task | Frequency | Best Method |

|---|---|---|

| Clean and Lubricate | Monthly | Use a soft cloth and appropriate oil |

| Threading Dial Accuracy Check | Before major projects | Compare with a known standard |

Future Trends in Lathe Technology

Innovations in lathe technology and upcoming upgrade options. Predictions for advancements in threading dial mechanisms.Exciting changes are coming in lathe technology. New designs will make lathes faster and easier to use. For example, users will see smart dials that can help with threading more accurately. Future upgrades will also include:

- Digital displays for better precision.

- Advanced materials that last longer and resist wear.

- Automation features for quick adjustments.

These improvements will not only save time but also make it safer for everyone to work with lathes.

What can we expect from future threading dials?

We can expect more advanced threading dials that are easier to read and adjust. They may even have automatic tracking to simplify the threading process, making it quicker and more accurate.

Conclusion

In summary, a lathe upgrade kit can greatly improve your metal lathe’s threading dial. You get better accuracy and smoother operations. Upgrading can save you time and effort in your projects. If you’re ready to enhance your lathe, consider exploring different kits available. Doing so can make your metalworking tasks easier and more enjoyable. Happy lathe upgrading!FAQs

What Are The Benefits Of Upgrading To A Threaded Dial On A Metal Lathe?Upgrading to a threaded dial on a metal lathe helps you work more easily. It lets you measure things more accurately. You can make better cuts and shapes for your projects. This upgrade also saves you time, so you can finish your work faster. Plus, it can help you create smoother, cleaner finished pieces.

How Do You Install A Threading Dial Upgrade Kit On A Metal Lathe?To install a threading dial upgrade kit on a metal lathe, you first need to turn off the machine. Then, take off any parts that block the old dial. Next, follow the instructions in your kit to put on the new dial. Make sure everything is tight and secure. Finally, test the new dial to see if it works well.

What Features Should I Look For In A Quality Threading Dial Upgrade Kit For My Lathe?When choosing a good threading dial upgrade kit for your lathe, look for a strong and durable design. Make sure it fits your lathe model well. A clear, easy-to-read scale is important too. You also want smooth movement for better accuracy. Finally, check for good instructions so you can install it easily.

Can A Threading Dial Upgrade Kit Improve The Accuracy Of Threading Operations On My Metal Lathe?Yes, a threading dial upgrade kit can help you make better threads on your metal lathe. It helps you line up the tool correctly, which means your threads will fit better. This kit can also make it easier for you to repeat the same threading process. With better tools, your work can be more precise and look nicer.

What Are Some Common Brands Or Models Of Threading Dial Upgrade Kits Available For Metal Lathes?Some common brands of threading dial upgrade kits for metal lathes include Grizzly, Jet, and South Bend. You can also find kits from brands like Enco and Haas. These brands make it easier for you to cut threads on your projects. Each kit may work differently, so check the instructions before using.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Benefits Of Upgrading To A Threaded Dial On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading to a threaded dial on a metal lathe helps you work more easily. It lets you measure things more accurately. You can make better cuts and shapes for your projects. This upgrade also saves you time, so you can finish your work faster. Plus, it can help you create smoother, cleaner finished pieces.”}},{“@type”: “Question”,”name”: “How Do You Install A Threading Dial Upgrade Kit On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a threading dial upgrade kit on a metal lathe, you first need to turn off the machine. Then, take off any parts that block the old dial. Next, follow the instructions in your kit to put on the new dial. Make sure everything is tight and secure. Finally, test the new dial to see if it works well.”}},{“@type”: “Question”,”name”: “What Features Should I Look For In A Quality Threading Dial Upgrade Kit For My Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a good threading dial upgrade kit for your lathe, look for a strong and durable design. Make sure it fits your lathe model well. A clear, easy-to-read scale is important too. You also want smooth movement for better accuracy. Finally, check for good instructions so you can install it easily.”}},{“@type”: “Question”,”name”: “Can A Threading Dial Upgrade Kit Improve The Accuracy Of Threading Operations On My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, a threading dial upgrade kit can help you make better threads on your metal lathe. It helps you line up the tool correctly, which means your threads will fit better. This kit can also make it easier for you to repeat the same threading process. With better tools, your work can be more precise and look nicer.”}},{“@type”: “Question”,”name”: “What Are Some Common Brands Or Models Of Threading Dial Upgrade Kits Available For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common brands of threading dial upgrade kits for metal lathes include Grizzly, Jet, and South Bend. You can also find kits from brands like Enco and Haas. These brands make it easier for you to cut threads on your projects. Each kit may work differently, so check the instructions before using.”}}]}