Have you ever tried to use a metal lathe, only to be frustrated by loud vibrations? You’re not alone. Many hobbyists and machinists face this problem. But what if I told you that reducing lathe vibration doesn’t have to cost a fortune?

Imagine getting smooth cuts without the annoying shaking. It might sound like a dream, but it’s possible with a cheap metal lathe. Many people don’t realize that simple changes can dramatically improve their experience.

Did you know some metal lathes can vibrate so much that they affect the quality of your work? This can lead to mistakes and wasted material. However, with a few clever tips, you can reduce that vibration.

In this article, we’ll explore effective, low-cost ways to tackle lathe vibrations. Get ready to transform your metal lathe experience into something you enjoy. Are you excited to learn more?

Lathe Vibration Reduction: Tips For A Cheap Metal Lathe

Lathe Vibration Reduction for Affordable Metal Lathes

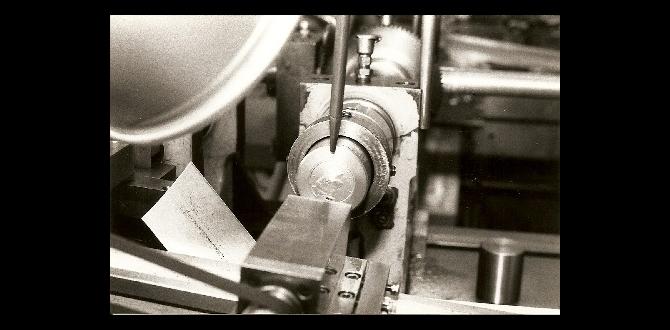

Finding a cheap metal lathe with reduced vibration can make a big difference in your projects. Excessive vibration can lead to poor cuts and increased wear on your tools. Simple techniques like adding rubber pads or using softer materials can help absorb those annoying vibrations. Did you know that even small changes can improve accuracy? You don’t have to break the bank to get smoother results. With these tips, achieving better performance from your lathe becomes easy and affordable.Understanding Lathe Vibration

Definition of lathe vibration and its causes. Impact of vibration on machining quality and precision.Lathe vibration happens when a lathe machine shakes or rattles while working. It can be caused by parts being loose, unbalanced tools, or worn bearings. This vibration can negatively impact the quality of the work. It can lead to:

- Inaccurate cuts

- Poor surface finish

- Shorter tool life

Without addressing vibration, it is hard to get precision in machining. Keeping everything well-maintained helps improve results.

What causes lathe vibration?

Lathe vibration can be caused by multiple factors, such as unbalanced tools, loose parts, and worn bearings. Proper maintenance and balancing tools can help reduce these vibrations.

Common Sources of Vibration in Metal Lathes

Mechanical issues: alignment, wear, and imbalances. External factors: environmental conditions and surface interactions.Vibrations in metal lathes can come from different places. Mechanical problems often cause these shakes. Issues like poor alignment, worn parts, and imbalances can make your lathe jiggle like a jelly on a roller coaster. External factors matter too. Things such as temperature changes and how the metal meets the tool can stir up trouble. Think of it this way: your lathe is a dance partner; if they step on your toes, you won’t enjoy the twirl! Here’s a quick look:

| Source | Description |

|---|---|

| Mechanical Issues | Poor alignment, wear and imbalances. |

| External Factors | Temperature changes and surface interactions. |

Importance of Vibration Reduction in Metalworking

Effect on tool life and performance. Influence on finished product quality.Metalworking is delicate. Vibration reduction is crucial for tools and products. Here’s why:

- Tool Life: Less vibration means tools last longer. They don’t wear out as fast.

- Performance: Vibration-free machines work better. They cut smoothly and accurately.

- Product Quality: Less vibration leads to better finishes. Parts look good and fit well.

In fact, studies show that reducing vibration can boost a tool’s lifespan by up to 30%. This is significant in metalworking. Higher quality products mean happier customers.

Why is vibration reduction important?

It helps keep tools sharp and products smooth. Shaking machines lead to rough cuts and broken tools.

Affordable Techniques for Lathe Vibration Reduction

Using vibration dampening pads or mats. Implementing proper lathe setup and alignment strategies.Want to keep your metal lathe purring like a kitten? Start by using vibration dampening pads or mats. These handy tools will absorb unwanted bumps and shakes like they’re soaking up spilled milk! Next, pay attention to your lathe setup and alignment. A well-set lathe is like a well-tuned band; it plays a smooth song instead of a confusing noise. A proper setup can significantly reduce vibrations and keep your projects on track.

| Technique | Description |

|---|---|

| Vibration Dampening Pads | Absorb vibrations and improve stability. |

| Proper Setup | Ensure correct alignment for smoother operation. |

DIY Solutions for Vibration Reduction

Crafting custom isolation mounts. Resourcing materials for costeffective vibration dampening.Building your own isolation mounts can be a fun project. You can use rubber pads or old tires for soft landings. These materials absorb vibrations, making your lathe quieter. Who knew your garage could be a science lab, right?

Looking for cheap but effective solutions? Check your local hardware store or even online marketplaces! Salvaged materials can work wonders for vibration dampening. Recycling is cool and it saves money, so your wallet will thank you. Don’t forget to measure twice; nobody likes a wobbly lathe!

| Material | Cost | Effectiveness |

|---|---|---|

| Rubber Pads | Low | Great |

| Old Tires | Free | Good |

| Wood Blocks | Low | Fair |

With a bit of creativity, you can significantly reduce vibration without breaking the bank. Your projects will run smoother, and your neighbors won’t think you’re auditioning for a rock band!

Maintenance Practices for Minimizing Vibration

Regular inspection and maintenance routines. Tips for maintaining tool sharpness and balance.To keep your lathe running smoothly, regular checks are important. Inspect for loose parts or wear and tear. This simple routine can prevent bigger issues later. Also, ensure your tools stay sharp and balanced:

- Sharpen tools after every few uses.

- Balance tools to avoid uneven cuts.

- Clean the lathe to remove dust and debris.

- Lubricate moving parts regularly.

By following these tips, you can reduce vibration and enhance performance.

How can I reduce vibration in my lathe?

To reduce vibration in your lathe, focus on maintaining sharp tools and balancing them well. Regular maintenance, like tightening loose parts, helps too. These practices keep your work steady and safe.

Impact of Lathe Vibration on Safety

How vibration can lead to safety hazards. Measures to enhance safety through vibration control.Vibration from a lathe can create serious safety issues. It can lead to accidents if not controlled. Workers may lose grip on tools or feel dizzy. This makes their work dangerous. To enhance safety, consider these measures:

- Regularly check the lathe for wear and tear.

- Use vibration dampening tools.

- Ensure proper machine setup and balance.

Taking these steps helps keep the workplace safer. A stable machine means fewer accidents and less stress. Remember, safety first!

How does lathe vibration impact safety?

Vibration can cause accidents, making it hard for operators to control tools and machines safely.

Case Studies: Successful Vibration Reduction Techniques

Examples of businesses that implemented lowcost solutions. Insights and results from vibration reduction strategies.Businesses have found clever ways to reduce lathe vibrations without breaking the bank. For example, one small workshop used rubber mats to absorb vibrations. This simple change saved them hundreds in repairs! Another company tried adding weight to their lathe, which helped stabilize it immensely. The result? Smoother operations and happier workers! It turns out, sometimes the best solutions are the easiest and cheapest ones. Who knew a bit of rubber could save the day?

| Business | Technique Used | Result |

|---|---|---|

| Small Workshop | Rubber Mats | Smoother operations, cost savings |

| Lathe Factory | Adding Weight | Stabilized machine, happier workers |

Conclusion

In summary, reducing lathe vibration on a cheap metal lathe can improve your work quality. Simple steps like balancing your workpiece and tightening loose parts can help. You can also explore rubber pads for better support. Remember, less vibration means smoother finishes! For more tips, consider reading guides on metalworking or checking out videos to learn more.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction For A Cheap Metal Lathe:Sure! Here are five related questions on the topic of lathe vibration reduction for a cheap metal lathe: 1. What can you do to stop the lathe from shaking? 2. Why does a lathe shake when you use it? 3. How can you make your lathe heavier? 4. What kind of pads can you use to stop vibrations? 5. How can you check your lathe for problems? To stop the lathe from shaking, you can add weight to it. Making it heavier helps it stay still. Use rubber pads under the lathe to absorb the shaking. This makes it safer and helps you make better parts. Always check the lathe for loose or broken parts, too!

Sure! Just let me know what question you want me to answer.

What Are Some Effective Methods To Reduce Vibration In A Budget-Friendly Metal Lathe?To reduce vibration in a metal lathe, you can start by making sure it’s on a stable and sturdy surface. You can add rubber pads or mats under the lathe to help absorb vibrations. It’s also a good idea to balance the tools and materials you use. Finally, keep the lathe clean and well-lubricated to help it run smoothly.

How Can The Placement And Leveling Of A Cheap Metal Lathe Impact Vibration Levels During Operation?The way you place and level a cheap metal lathe is very important. If it’s not level, it can shake a lot when you use it. This shaking, or vibration, can make it hard to work and can even break things. Make sure you set it on a flat surface and adjust the legs so it’s even. This helps keep the lathe stable and working well.

What Types Of Damping Materials Or Accessories Can Be Used To Minimize Lathe Vibrations Without Significant Investment?You can use rubber mats under the lathe to help absorb vibrations. Foam pads between the lathe and its legs also work well. Adding weights, like sandbags, can help keep it steady. You can even use old carpet pieces to cushion it. All these are easy and cheap ways to reduce vibration!

Are There Specific Tool Post Designs Or Modifications That Can Help Reduce Chatter And Vibration In Inexpensive Metal Lathes?Yes, there are some tool post designs that can help. Using a heavier tool post can make it steadier. You can also add rubber or foam padding to absorb shocks. Tightening screws well helps keep things stable. Finally, choosing the right tool angles can reduce chatter too.

What Routine Maintenance Practices Can Be Implemented To Prevent Excessive Vibration In A Low-Cost Lathe?To stop a low-cost lathe from shaking too much, you can do a few easy things. First, check the lathe’s legs and make sure they are tight and level. Next, clean off any dust or dirt. This can help the lathe run smoothly. Lastly, inspect the belts and parts for wear, and replace anything that’s broken.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction For A Cheap Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on the topic of lathe vibration reduction for a cheap metal lathe: 1. What can you do to stop the lathe from shaking? 2. Why does a lathe shake when you use it? 3. How can you make your lathe heavier? 4. What kind of pads can you use to stop vibrations? 5. How can you check your lathe for problems? To stop the lathe from shaking, you can add weight to it. Making it heavier helps it stay still. Use rubber pads under the lathe to absorb the shaking. This makes it safer and helps you make better parts. Always check the lathe for loose or broken parts, too!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are Some Effective Methods To Reduce Vibration In A Budget-Friendly Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in a metal lathe, you can start by making sure it’s on a stable and sturdy surface. You can add rubber pads or mats under the lathe to help absorb vibrations. It’s also a good idea to balance the tools and materials you use. Finally, keep the lathe clean and well-lubricated to help it run smoothly.”}},{“@type”: “Question”,”name”: “How Can The Placement And Leveling Of A Cheap Metal Lathe Impact Vibration Levels During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The way you place and level a cheap metal lathe is very important. If it’s not level, it can shake a lot when you use it. This shaking, or vibration, can make it hard to work and can even break things. Make sure you set it on a flat surface and adjust the legs so it’s even. This helps keep the lathe stable and working well.”}},{“@type”: “Question”,”name”: “What Types Of Damping Materials Or Accessories Can Be Used To Minimize Lathe Vibrations Without Significant Investment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use rubber mats under the lathe to help absorb vibrations. Foam pads between the lathe and its legs also work well. Adding weights, like sandbags, can help keep it steady. You can even use old carpet pieces to cushion it. All these are easy and cheap ways to reduce vibration!”}},{“@type”: “Question”,”name”: “Are There Specific Tool Post Designs Or Modifications That Can Help Reduce Chatter And Vibration In Inexpensive Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some tool post designs that can help. Using a heavier tool post can make it steadier. You can also add rubber or foam padding to absorb shocks. Tightening screws well helps keep things stable. Finally, choosing the right tool angles can reduce chatter too.”}},{“@type”: “Question”,”name”: “What Routine Maintenance Practices Can Be Implemented To Prevent Excessive Vibration In A Low-Cost Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stop a low-cost lathe from shaking too much, you can do a few easy things. First, check the lathe’s legs and make sure they are tight and level. Next, clean off any dust or dirt. This can help the lathe run smoothly. Lastly, inspect the belts and parts for wear, and replace anything that’s broken.”}}]}