Have you ever noticed how vibrations can ruin your projects on a metal lathe? Imagine your carefully crafted design wobbling around. It can be frustrating, right? Luckily, there are metal lathe accessories designed to reduce lathe vibration. These tools can make a big difference in your work.

Many people don’t realize how much vibration can affect the quality of their projects. Did you know a little vibration could lead to big errors? With the right accessories, you can keep your lathe steady. This means smoother cuts and better surfaces. Sounds great, doesn’t it?

In this article, we will explore some of the best metal lathe accessories for vibration reduction. You’ll learn how these tools work and how they can improve your lathe experience. Get ready to transform your projects and enjoy the art of metalworking even more!

Lathe Vibration Reduction: Essential Metal Lathe Accessories Lathe Vibration Can Significantly Affect The Quality Of Machining Operations, Leading To Inaccuracies And An Unsatisfactory Finish. Fortunately, Various Accessories Can Help Reduce Vibration And Improve Overall Performance. In This Article, We Will Explore The Essential Metal Lathe Accessories Designed For Lathe Vibration Reduction, Ensuring Your Projects Achieve The Precision They Deserve. Understanding Lathe Vibration Lathe Vibration Can Stem From Multiple Sources, Including Unbalanced Workpieces, Tool Chatter, Inadequate Mounting, And Even The Machine’S Inherent Vibrations. These Vibrations Can Lead To Several Problems, Such As Poor Surface Finish, Tool Wear, And Reduced Machining Efficiency. Essential Metal Lathe Accessories For Vibration Reduction 1. **Vibration Dampening Pads**: These Pads Are Placed Under The Lathe To Absorb And Dissipate Vibrations Before They Transfer To The Workpiece. Made From Rubber Or Specialized Materials, They Offer Significant Improvement In Stability. 2. **Stabilizing Tool Holders**: Tool Holders That Feature A Larger Mass And Specialized Geometry Can Reduce Vibrations When Cutting. They Provide More Stability During Machining Operations. 3. **Balanced Tooling**: Investing In Balanced Cutters And Tools Is Crucial. Unbalanced Tooling Can Contribute To Excessive Vibration, While Balanced Tools Run Smoother And Produce Better Results. 4. **Chatter-Free Cutting Techniques**: Utilizing Specific Cutting Techniques And Speeds Can Minimize Vibration. Accessories Like Anti-Vibration Boring Bars Can Also Help In Maintaining Consistency. 5. **Proper Workpiece Mounting**: Ensuring That The Workpiece Is Securely And Correctly Mounted Is Key In Reducing Vibrations. Accessories Like Upgraded Chucks And Vises Can Provide Improved Grip And Stability. 6. **Vibration Monitoring Systems**: Advanced Technologies Now Allow For Real-Time Monitoring Of Vibrations. Incorporating Monitors Can Help Identify Issues Early, Allowing For Adjustments To Be Made Quickly. Conclusion Reducing Lathe Vibrations Can Vastly Improve The Outcomes Of Your Machining Projects. By Investing In The Right Metal Lathe Accessories, You Can Mitigate Unwanted Vibrations, Enhance Precision, And Achieve A Better Surface Finish. Incorporate These Essential Tools And Techniques Into Your Lathe Setup For Noticeable Improvements In Your Machining Operations.

Lathe Vibration Reduction: Key Metal Lathe Accessories

Do you know that reducing lathe vibration can improve your metalworking? Specific accessories can help. First, consider using rubber feet to absorb vibrations. They keep your lathe steady. Next, a quality chuck can help secure your workpiece better, minimizing wobbling. Additionally, a sturdy stand is essential. It keeps your lathe balanced during use. By choosing the right accessories, you can make your metal lathe run smoother and enhance your projects. Wouldn’t it be great to create precise pieces every time?Understanding Lathe Vibration

Definition and causes of lathe vibration. Importance of vibration reduction in machining processes.Lathe vibration happens when the machine shakes while working. This shaking can come from many things, like a dull tool or uneven material. It can make cuts less smooth and even damage the workpiece. Reducing this vibration is key. Less vibration means better quality in machining. It also helps the machine last longer and keeps you safe. Remember, good tools make good work!

What is the importance of reducing lathe vibration?

Reducing lathe vibration helps create better work surfaces, improves tool life, and makes machines safer to operate.

Benefits of Reducing Vibration:

- Improved machining quality

- Longer tool lifespan

- Increased operator safety

Impact of Vibration on Metalworking

Effects of vibration on workpiece quality. Longterm implications for machine tools and operator safety.Vibration during metalworking can cause big problems. It affects the quality of the workpiece, making it less precise. Over time, this can harm the lathe and even put operators at risk. Keeping machines steady is vital for safety and performance.

- Vibration leads to poor cuts and rough surfaces.

- Machines may wear out quicker, needing more repairs.

- Operators can face injuries from working with unstable equipment.

How does vibration change work quality?

Vibration can create uneven surfaces and weak spots in metal pieces. This means the final product may not meet the needed standards.

What are the long-term effects on machines and safety?

Machines exposed to frequent vibration might break down more often. It can also lead to accidents, putting worker safety at risk.

Stabilizers and Dampers

Types of stabilizers available for metal lathes. Benefits of using dampers to mitigate vibrations.Think of stabilizers and dampers as the superhero sidekicks for your metal lathe. There are various types of stabilizers, like support brackets and damping pads, that help keep your machine steady. These clever accessories make sure your lathe doesn’t wobble like a jelly on a roller coaster. Dampers are like cozy blankets for vibrations; they absorb shock and reduce chatter. This means smoother cuts and less wear. So, suit up your lathe—it’s time to wave goodbye to those annoying shakes!

| Type of Stabilizers | Benefits |

|---|---|

| Support Brackets | Provides extra stability and supports heavy workpieces. |

| Damping Pads | Absorbs vibrations and eliminates noise. |

| Weight Balancers | Helps distribute weight evenly for smoother operation. |

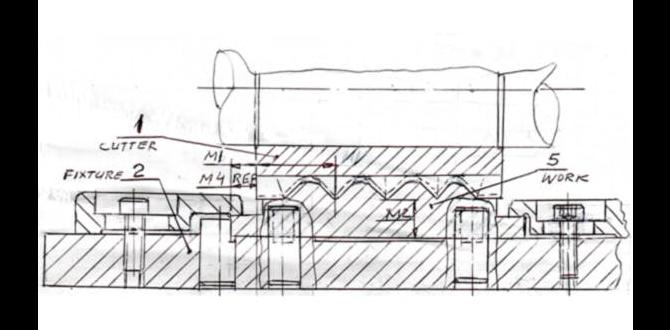

Precision Tool Holders

The role of precision tool holders in minimizing vibration. Recommended brands and models for optimal performance.Precision tool holders play a key role in reducing vibrations during machining. They securely hold cutting tools, ensuring stability and accuracy. This helps create smoother finishes on metal parts. Quality tool holders can make a big difference in performance. Recommended brands include:

- Collet Chucks – Great for tight gripping.

- Tool Holders from Sandvik – Known for durability.

- Haas Automation – Offers reliable options.

Choosing the right tool holder boosts efficiency and minimizes vibration.

What are the benefits of using precision tool holders?

The main benefits include improved accuracy, reduced vibration, and better tool life. They allow machines to work effectively, leading to high-quality finished products.

Upgrade Options for Lathe Bed and Base

The significance of a sturdy lathe base in vibration reduction. Customizing or reinforcing lathe beds: pros and cons.A strong lathe base is important for reducing vibration. A heavy base helps keep the lathe steady. This makes your work smoother and more precise. Customizing or reinforcing lathe beds can also be helpful. However, it has some pros and cons. Here are a few:

- Pros: Custom bases can be tailored for your specific needs.

- Cons: Customization may increase costs and time needed to set up.

Choosing the right options helps improve your lathe’s performance. Always think about what works best for your projects.

Why is a sturdy lathe base important?

A sturdy base helps minimize vibrations. This leads to better accuracy while working. Sturdy bases support larger projects too.

What are the benefits of customizing a lathe bed?

Customizing a lathe bed can enhance your workspace. However, it might cost more than a regular one.

Regular Maintenance Practices

Maintenance routines to minimize vibration effects. Key adjustments and checks for optimal performance.To keep your lathe running well, you need regular care. This helps lower vibrations and improve performance. Here are easy maintenance steps:

- Check the belts and pulleys for wear.

- Lubricate moving parts to reduce friction.

- Align the tailstock and headstock correctly.

- Inspect the bed for wear and tear.

Doing these tasks helps you maintain a steady and smooth operation. Regular checks can prevent bigger problems. Isn’t it great when your tools work perfectly?

What are the key adjustments for lathe performance?

Key adjustments include checking alignment, tightening loose screws, and ensuring proper tool height.

Why is maintenance important?

Regular maintenance extends the life of your lathe and enhances safety, helping you stay productive and efficient.

Case Studies and User Experiences

Realworld examples of vibration reduction success stories. Testimonials from metalworking professionals.Many professionals have shared their success stories about reducing lathe vibrations. For example, John, a metalworker, noticed his projects improved drastically after using a special vibration dampening accessory. His machines now sing rather than rattle! Another expert, Sarah, said her finishing work became smoother, almost as if her lathe had a spa day. These stories show that the right accessories can make a big difference. Here’s a table of some real user experiences:

| Name | Experience |

|---|---|

| John | Vibration dampening made projects smoother! |

| Sarah | Lathe felt like it had a spa day! |

| Mike | Reduced wear and tear on tools. |

These testimonials prove that quality accessories can help your metal lathe work wonders. Less vibration means sharper cuts and happier metalworkers!

Future Trends in Vibration Reduction Technology

Innovations in lathe accessories aimed at vibration control. Predictions for the evolution of metal lathe technology.New tools and upgrades are changing how we reduce vibration in metal lathes. Innovative accessories help make lathes run smoothly. Companies are working hard to improve these tools. In the future, we might see:

- Smart sensors that detect vibrations.

- Advanced materials to absorb shocks.

- Designs that focus on stability.

By changing how we build lathes, we can expect higher precision and safer operation. Experts believe this will lead to even better performance in the years ahead.

What are some new trends in vibration control for lathes?

New trends include smart sensors, better materials, and improved designs. These changes will help lathes work more quietly and accurately.

Conclusion

In conclusion, reducing lathe vibration is essential for better machining results. Using specific accessories like dampers and vibration pads can help. These tools improve precision and extend your lathe’s life. You can try different accessories to find what works best for you. For more tips and methods on lathe maintenance, consider reading further or experimenting hands-on. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction And Metal Lathe Accessories:Sure! Here are some things to know about reducing vibration in a lathe and its accessories. 1. **What is lathe vibration?** Lathe vibration happens when the machine shakes while running. This can make your work uneven or messy. 2. **How can we reduce lathe vibration?** We can reduce vibration by balancing the lathe properly and using good mounts. This helps keep the machine steady. 3. **Why should you use good accessories?** Good accessories, like sturdy tool holders, help keep everything stable. This makes your work safer and cleaner. 4. **What are dampers?** Dampers are special parts that absorb shock and reduce vibration. You can add them to your lathe to make it work better. 5. **Can vibration affect our work?** Yes, too much vibration can cause mistakes in your work. It’s important to keep everything steady for the best results.

Sure! Please share your question, and I’ll be happy to help you with an answer.

What Are The Most Effective Accessories For Reducing Vibration On A Metal Lathe?To reduce vibration on a metal lathe, you can use rubber feet or pads. These help absorb shock and keep the lathe steady. Adding a heavy base also helps, as it makes the machine more balanced. You can use dampening mats or strips too. They soak up vibrations, making your work smoother.

How Can Adjusting The Lathe’S Setup And Alignment Help Minimize Vibrations During Machining?Adjusting a lathe’s setup and alignment helps make it work better. When we make sure everything is straight and tight, the lathe doesn’t shake as much. This means smoother cutting and better-looking parts. It’s like making sure a toy car’s wheels are straight so it rolls nicely. Less vibration helps keep things stable and safe while you’re working.

What Role Do Dampening Pads Or Feet Play In Vibration Reduction For Metal Lathes?Dampening pads or feet help reduce vibrations in metal lathes. When the lathe runs, it can shake and make noise. These pads absorb some of the shaking. This makes the machine quieter and more stable, so you get better work from your lathe. Without them, the vibrations could make it harder to cut metal properly.

Can Adding A Heavier Tailstock Or Bed Support Help Reduce Vibrations In A Lathe Operation?Yes, adding a heavier tailstock or bed support can help reduce vibrations. When a lathe is more stable, it shakes less. A heavier tailstock keeps everything steady while you work. This means you can make better, smoother cuts. It’s like having extra weight to hold things down.

What Maintenance Practices Can Be Implemented To Prevent Excessive Vibration In Metal Lathes?To stop metal lathes from shaking too much, we can do a few things. First, check and tighten all the screws and bolts. This keeps everything in place. Next, make sure everything is clean. Dirt can cause problems. Finally, we should look at the parts often and replace any that are worn out. This helps the lathe work smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction And Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some things to know about reducing vibration in a lathe and its accessories. 1. **What is lathe vibration?** Lathe vibration happens when the machine shakes while running. This can make your work uneven or messy. 2. **How can we reduce lathe vibration?** We can reduce vibration by balancing the lathe properly and using good mounts. This helps keep the machine steady. 3. **Why should you use good accessories?** Good accessories, like sturdy tool holders, help keep everything stable. This makes your work safer and cleaner. 4. **What are dampers?** Dampers are special parts that absorb shock and reduce vibration. You can add them to your lathe to make it work better. 5. **Can vibration affect our work?** Yes, too much vibration can cause mistakes in your work. It’s important to keep everything steady for the best results.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share your question, and I’ll be happy to help you with an answer.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Accessories For Reducing Vibration On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration on a metal lathe, you can use rubber feet or pads. These help absorb shock and keep the lathe steady. Adding a heavy base also helps, as it makes the machine more balanced. You can use dampening mats or strips too. They soak up vibrations, making your work smoother.”}},{“@type”: “Question”,”name”: “How Can Adjusting The Lathe’S Setup And Alignment Help Minimize Vibrations During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting a lathe’s setup and alignment helps make it work better. When we make sure everything is straight and tight, the lathe doesn’t shake as much. This means smoother cutting and better-looking parts. It’s like making sure a toy car’s wheels are straight so it rolls nicely. Less vibration helps keep things stable and safe while you’re working.”}},{“@type”: “Question”,”name”: “What Role Do Dampening Pads Or Feet Play In Vibration Reduction For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Dampening pads or feet help reduce vibrations in metal lathes. When the lathe runs, it can shake and make noise. These pads absorb some of the shaking. This makes the machine quieter and more stable, so you get better work from your lathe. Without them, the vibrations could make it harder to cut metal properly.”}},{“@type”: “Question”,”name”: “Can Adding A Heavier Tailstock Or Bed Support Help Reduce Vibrations In A Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, adding a heavier tailstock or bed support can help reduce vibrations. When a lathe is more stable, it shakes less. A heavier tailstock keeps everything steady while you work. This means you can make better, smoother cuts. It’s like having extra weight to hold things down.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Prevent Excessive Vibration In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stop metal lathes from shaking too much, we can do a few things. First, check and tighten all the screws and bolts. This keeps everything in place. Next, make sure everything is clean. Dirt can cause problems. Finally, we should look at the parts often and replace any that are worn out. This helps the lathe work smoothly.”}}]}