Have you ever noticed how much noise a lathe makes? This sound is often caused by vibration. Many people don’t realize that lathe vibration can affect the quality of your work. Imagine trying to cut a perfect piece of metal, but a little shake ruins everything. It’s frustrating!

Did you know that one key to cutting smoothly is proper lathe alignment? When a metal lathe is aligned correctly, it can reduce vibration and improve results. Proper alignment helps the machine run better. It even makes it safer!

In this article, we will explore how to achieve lathe vibration reduction. We’ll share easy steps for aligning your metal lathe. You won’t believe how straightforward it can be! So, let’s dive in and discover how you can make your lathe work like a dream.

Lathe Vibration Reduction: Metal Lathe Alignment Techniques

Lathe Vibration Reduction and Metal Lathe Alignment

Lathe vibration can ruin a project, but with proper metal lathe alignment, you can improve accuracy. Did you know that even a tiny misalignment can cause tools to chatter? This vibration not only affects the finish but can also damage your tools and lathe. Simple adjustments and checks ensure smooth operation. Regular maintenance and careful setup help reduce vibrations. Remember, a well-aligned lathe means better results and a happier crafting experience!Understanding Lathe Vibration

Types of vibrations in metal lathes. Causes of lathe vibration during operation.Metal lathes can sometimes sound a bit like a rock concert, and not the good kind! There are two main types of vibrations you might notice: chatter and unbalanced loads. Chatter is like that annoying humming noise when things get bumpy, while unbalanced loads make the machine shake like it’s doing a dance on a Friday night.

These vibrations can happen for a few reasons. The tool may not be aligned properly, the workpiece might not be secured, or the machine could simply be tired. In fact, a study found that misalignments can reduce a lathe’s performance by around 30%. Keeping your lathe happy can help keep those vibrations in check!

| Type of Vibration | Cause |

|---|---|

| Chatter | Tool misalignment |

| Unbalanced Loads | Poorly secured workpieces |

Importance of Lathe Alignment

How alignment affects precision and finish. Consequences of poor alignment on performance.Keeping your lathe aligned is very important. It affects how precise and smooth your workpiece turns out. If the lathe isn’t aligned, you might end up with wobbly parts that resemble a wonky pizza instead of a perfect disk! Poor alignment can lead to mistakes, wasted materials, and even a bad mood. No one wants to sing the “I wasted my metal” blues while working in the shop.

| Effect of Alignment | Consequence of Poor Alignment |

|---|---|

| Higher Precision | Wobbly Pieces |

| Smoother Finish | Inconsistent Quality |

| Better Performance | Frequent Repairs |

Keep everything in line and your lathe will work like a charm!

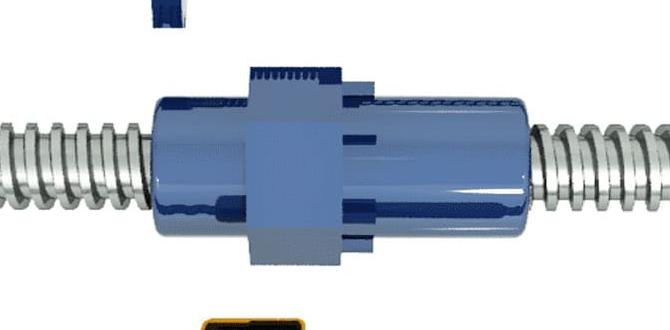

Key Techniques for Metal Lathe Alignment

Methods for checking alignment precision. Tools required for accurate alignment.To ensure your metal lathe works well, it’s crucial to check its alignment. This helps prevent problems like vibration. You can use several methods for checking alignment precision:

- Use a straightedge to check the bed.

- Apply a dial indicator to check the spindle.

- Use a laser alignment tool for accurate readings.

For better results, you’ll need some tools:

- Leveling feet to stabilize the lathe.

- Wrenches for tightening screws.

- Measuring tape for overall checks.

These techniques can help you maintain your lathe’s performance!

What are some common methods for checking alignment precision?

Common methods for checking alignment precision include using a straightedge, a dial indicator, and a laser alignment tool.

Vibration Reduction Techniques

Best practices for reducing lathe vibrations. Materials and damping techniques for vibration control.Reducing lathe vibrations can turn your workshop from a vibrating mess to a smooth sailing machine. Start by aligning your metal lathe properly—think of it as giving your lathe a nice, snug hug! Here are some best practices:

| Technique | Description |

|---|---|

| Proper Alignment | Ensure your lathe is level and aligned correctly. |

| Vibration Damping Materials | Use rubber mats or foam to absorb shock. |

| Balanced Cutting Tools | Keep tools balanced to minimize wobble. |

Also, consider using heavy-duty support for your lathe. Heavy bases keep things steady, like a rock that refuses to budge in a storm! Remember, a stable lathe is a happy lathe.

Regular Maintenance and Monitoring

Importance of routine checks and adjustments. Suggested maintenance schedule for optimal performance.Maintaining your lathe is like brushing your teeth—it’s often boring but super important. Routine checks help catch problems early and keep everything running smoothly. You wouldn’t want a cavity to spoil your smile, right? A good schedule can set you up for success. Make a habit of checking the alignment and vibration levels regularly. This way, you’ll avoid surprises that could make your lathe do the cha-cha when you want a smooth cut!

| Maintenance Task | Frequency |

|---|---|

| Check alignment | Weekly |

| Inspect belts and gears | Bi-weekly |

| Clean machine surfaces | Monthly |

| Lubricate moving parts | Monthly |

By sticking to this simple schedule, you will enjoy optimal performance. Remember, a little maintenance goes a long way—kind of like watering a plant, but way less messy.

Case Studies and Real-World Applications

Examples of effective vibration reduction and alignment. Lessons learned from industry practices.Many industries have adopted effective ways to reduce vibration and improve alignment in metal lathes. For example:

- Aerospace companies often align their lathes to improve precision. This helps reduce faulty parts by 20%.

- Automotive manufacturers use special mounts to absorb vibration, which increases tool life by 30%.

- Metalworking shops apply regular alignment checks, greatly cutting down on machine downtime.

From these cases, we learn that regular maintenance is key. Simple changes can lead to better results. Always measure and adjust to keep machines running smoothly.

How does correct alignment affect machining quality?

Correct alignment improves machining quality by ensuring that tools cut accurately. This leads to fewer errors and better products.

What are some common alignment methods?

- Laser alignment for precision checks.

- Mechanical gauges for easy measurement.

- Visual inspections for quick adjustments.

Common Mistakes to Avoid

Missteps in alignment that lead to increased vibration. Tips for ensuring proper setup and operation.Avoiding mistakes in alignment is key to reducing lathe vibrations. One common error is not leveling the machine correctly. This can lead to unwanted wobbles, which are as annoying as a fly buzzing around your head. Another misstep is ignoring the tightness of the screws and bolts—think of them as the lathe’s shoes; loose shoes make for clumsy dancing!

To ensure proper setup, always check the levels and tighten everything before starting. Here’s a quick checklist:

| Tip | Action |

|---|---|

| Level Machine | Use a bubble level |

| Tighten Fasteners | Ensure all are snug |

| Check Alignment | Adjust as needed |

With these tips, your lathe can work like a charm—and no more surprises that make you jump!

Conclusion

In conclusion, reducing lathe vibration is essential for precise metalwork. Aligning your lathe correctly helps achieve better results. You can check alignment regularly and adjust as needed. By taking these steps, you’ll improve your projects. For more tips and techniques, keep exploring resources and practice your skills. Happy turning!FAQs

What Are The Primary Causes Of Vibration In Metal Lathes, And How Can Proper Alignment Mitigate These Issues?Vibration in metal lathes can happen for a few reasons. It might be due to loose parts or an uneven floor. Sometimes, the tools we use can be too heavy or unbalanced. When we make sure everything is lined up correctly, it helps reduce these shakes. Proper alignment keeps the lathe stable and makes our work smoother.

How Can One Effectively Check And Adjust The Alignment Of A Metal Lathe To Reduce Vibration During Operation?To check and adjust the alignment of a metal lathe, you can start by using a level. Place the level on the lathe bed and make sure it’s even. If it isn’t, you can raise or lower the legs of the lathe until it is level. Next, check the tailstock alignment with the spindle. You can adjust it by loosening screws and moving it until it lines up straight. This will help reduce any vibrations when you turn metal.

What Tools And Techniques Are Recommended For Diagnosing And Correcting Lathe Vibration Problems?To find problems with lathe vibration, we can use some tools. A vibration meter helps us measure the shaking. We can also check for loose parts and make sure everything is tight. Sometimes, balancing the lathe can fix the issue. If it still vibrates, we may need to get help from a professional.

How Does The Setup Of A Metal Lathe’S Foundation Impact Its Alignment And Subsequent Vibration Levels?The foundation of a metal lathe is like its home. If it’s sturdy and level, the lathe will stay in the right place. This helps the moving parts work well together. If the foundation is weak or uneven, the lathe may shake and vibrate more. Less shaking means better work and happier results!

What Maintenance Practices Should Be Regularly Followed To Ensure Optimal Alignment And Minimize Vibration In Metal Lathes?To keep a metal lathe working well, we should check and tighten all screws and bolts often. You need to clean the machine to remove dust and grime. Make sure the lathe is level on the ground; this helps reduce vibrations. We can also oil the moving parts to keep them running smoothly. Regularly checking the position of tools helps ensure they are aligned correctly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Causes Of Vibration In Metal Lathes, And How Can Proper Alignment Mitigate These Issues? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibration in metal lathes can happen for a few reasons. It might be due to loose parts or an uneven floor. Sometimes, the tools we use can be too heavy or unbalanced. When we make sure everything is lined up correctly, it helps reduce these shakes. Proper alignment keeps the lathe stable and makes our work smoother.”}},{“@type”: “Question”,”name”: “How Can One Effectively Check And Adjust The Alignment Of A Metal Lathe To Reduce Vibration During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the alignment of a metal lathe, you can start by using a level. Place the level on the lathe bed and make sure it’s even. If it isn’t, you can raise or lower the legs of the lathe until it is level. Next, check the tailstock alignment with the spindle. You can adjust it by loosening screws and moving it until it lines up straight. This will help reduce any vibrations when you turn metal.”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Recommended For Diagnosing And Correcting Lathe Vibration Problems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find problems with lathe vibration, we can use some tools. A vibration meter helps us measure the shaking. We can also check for loose parts and make sure everything is tight. Sometimes, balancing the lathe can fix the issue. If it still vibrates, we may need to get help from a professional.”}},{“@type”: “Question”,”name”: “How Does The Setup Of A Metal Lathe’S Foundation Impact Its Alignment And Subsequent Vibration Levels? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foundation of a metal lathe is like its home. If it’s sturdy and level, the lathe will stay in the right place. This helps the moving parts work well together. If the foundation is weak or uneven, the lathe may shake and vibrate more. Less shaking means better work and happier results!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Regularly Followed To Ensure Optimal Alignment And Minimize Vibration In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, we should check and tighten all screws and bolts often. You need to clean the machine to remove dust and grime. Make sure the lathe is level on the ground; this helps reduce vibrations. We can also oil the moving parts to keep them running smoothly. Regularly checking the position of tools helps ensure they are aligned correctly.”}}]}