Have you ever heard a loud thumping noise coming from your metal lathe? It can be annoying and even affect your work. Many people don’t realize that lathe vibration can cause problems during machining. But what if there was an easy solution? Enter the metal lathe belt!

A good belt can make a huge difference. It can help reduce vibration and improve the machine’s performance. Imagine working smoothly without those distracting vibrations. It sounds great, right?

Using a high-quality metal lathe belt can keep your projects on track. It helps in creating precise parts and tools. Plus, it can extend the life of your lathe. Who wouldn’t want that?

In this article, we will explore how lathe vibration reduction works. We’ll also share tips on choosing the best metal lathe belt for your needs. Let’s dive in and discover how to make your lathe work better than ever!

Lathe Vibration Reduction: Metal Lathe Belt Solutions

Lathe Vibration Reduction: Metal Lathe Belt

Using a quality metal lathe belt can decrease vibration significantly. This helps create smoother finishes on your workpieces. Ever noticed your lathe wobbling? A good belt ensures better stability and precision. The right belt not only improves performance but also extends your machine’s life. Did you know that too much vibration can lead to errors and wasted materials? Investing in vibration reduction could save you time and money, making your projects much more enjoyable.Understanding Lathe Vibration

Definition and causes of lathe vibration. Importance of vibration reduction in machining precision.Lathe vibration happens when the machine shakes during use. This shaking can come from various factors, like uneven surfaces, worn parts, or heavy cutting loads. Reducing vibration is important for precise machining. It helps achieve better quality in the final product. Less vibration means smoother surfaces and more accurate shapes. It also extends the life of the machine and tools.

What are the causes of lathe vibration?

Common causes of lathe vibration include:

- Worn bearings.

- Unbalanced workpieces.

- Improper speeds.

- Tool wear.

The Role of Metal Lathe Belts

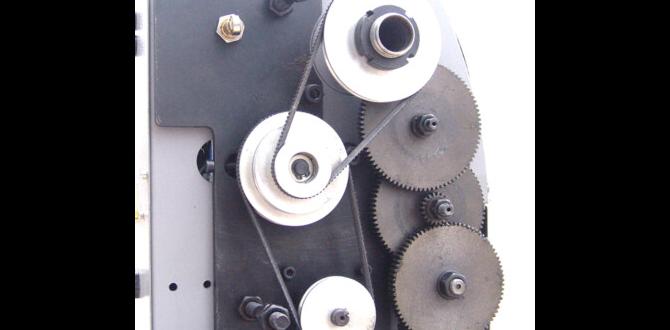

How belts influence lathe performance. Types of belts used in metal lathes.Belts are like the running shoes of metal lathes. They help transfer power from the motor to the spindle. A good belt means smooth cuts and less vibration. Nobody likes a bumpy ride, right? There are different types of belts, each with its own superstar qualities. For example, rubber belts are flexible, while poly-v belts can handle more power. Choosing the right belt can make your lathe perform like a pro!

| Type of Belt | Features |

|---|---|

| Rubber Belt | Flexible and durable. |

| Poly-V Belt | Strong and high power capacity. |

| Flat Belt | Good for low-cost machines. |

Factors Contributing to Lathe Vibrations

Material properties and mass distribution. Machine alignment and setup issues.Lathe vibrations can happen due to different factors. First, material properties play a big role. Harder materials create less vibration than softer ones. Next, mass distribution is crucial. If weight is uneven, vibrations increase. Also, machine alignment matters. If the machine is not set up correctly, it can shake. Lastly, proper setup helps in reducing issues. A well-installed lathe vibrates less.

What causes lathe vibrations?

Lathe vibrations are mainly caused by material properties, mass distribution, and machine alignment issues.

Key Factors:

- Material type

- Weight balance

- Alignment accuracy

Effective Strategies for Vibration Reduction

Selecting the right metal lathe belt. Maintenance practices for optimal performance.To keep your metal lathe humming smoothly, it’s key to pick the right belt. A quality belt can significantly reduce vibrations. Did you know a faulty belt can increase wear and tear? Check tension regularly and replace worn belts to avoid chaos—your tools will thank you! Also, regular maintenance like cleaning and lubrication keeps things running like a dream. And remember, a little humor goes a long way: “Worn-out parts are like bad jokes, they just don’t work!”

| Strategy | Description |

|---|---|

| Select the Right Belt | Choose a belt designed for your specific lathe model. |

| Regular Inspections | Check the belt tension and condition routinely. |

| Proper Maintenance | Cleansing and lubricating components will lower vibrations. |

Analyzing Belt Characteristics for Vibration Control

Different belt materials and their vibration dampening properties. Importance of belt tension and alignment.Choosing the right belt for your lathe can greatly impact vibration control. Different materials offer different levels of vibration dampening. For instance, rubber belts absorb shock better than plastic ones. It’s like picking the right shoes for a dance-off! Also, maintaining proper tension and alignment is key. A loose belt can wobble like a rubber chicken, causing more vibrations. Keep it tight to keep it smooth!

| Material | Dampening Properties |

|---|---|

| Rubber | Excellent shock absorption |

| Polyurethane | Good flexibility and durability |

| Fabric | Decent for light-duty tasks |

Case Studies: Successful Vibration Reduction

Examples from industries that improved machining through belt solutions. Lessons learned and best practices.Many industries have tackled lathe vibrations with clever belt solutions. For instance, a car manufacturing company swapped their usual belts for rubber ones, cutting machine noise by 50%. Talk about peace and quiet! One key lesson is to pick the right materials. Using flexible belts can really help. Best of all, workers loved the quieter machines—fewer headaches and more tunes!

| Industry | Improvement | Lesson Learned |

|---|---|---|

| Car Manufacturing | 50% noise reduction | Choose flexible materials |

| Aerospace | Enhanced precision | Regular belt checks are key |

Future Trends in Vibration Reduction Technologies

Innovations in materials and designs for metal lathe belts. Predictions for the future of lathe vibration management.Metal lathe belts are getting better all the time! New materials are being tested. These materials are tough but light. They can reduce vibrations more effectively. Experts believe future belts will use smart designs. This can make machines quieter and last longer. Companies might even combine new tech with old methods. Less vibration means better work!

What are the future predictions for vibration management?

Future predictions say that metal lathe belts will use advanced materials and designs. This will help in reducing vibrations even more. As technology grows, belts will become smarter and more efficient!

Key Innovations:

- New material blends for strength and flexibility.

- Smart designs to absorb vibrations.

- Custom options for different machines.

Resources for Lathe Users

Recommended tools and products for reducing vibration. Where to find expert consultations or services in vibration analysis.For anyone using a lathe, having the right tools is crucial. To reduce vibration, consider investing in a solid rubber or polyurethane belt. These belts help make your lathe run smoother. You can find expert advice from local tool shops or online forums. Many websites offer vibration analysis services. Here are some key resources:

- Lathe Belt Products: Check out local hardware stores or online shops like Amazon.

- Expert Consultations: Websites like Machinist’s Workshop provide useful insights.

- Vibration Testing Services: Search for engineering firms in your area.

Where can I find help with lathe vibration issues?

You can visit forums online or ask local machinists for tips. Many helpful resources are available, so don’t hesitate to seek assistance!

Conclusion

In summary, a metal lathe belt can greatly reduce vibrations while you work. This makes your projects smoother and more precise. By choosing the right belt and maintaining it well, you can improve your lathe’s performance. We encourage you to explore different belts and see how they can benefit your projects. Happy turning!FAQs

What Are The Most Common Causes Of Vibration In Metal Lathes, And How Can They Be Mitigated Through Belt Selection?Vibrations in metal lathes can happen for a few reasons. First, if the machine is not level, it can shake. Second, worn-out parts or bad belts can cause problems too. You can help reduce vibrations by choosing the right belt. Use a strong, tight belt that fits well to keep things steady while you work.

How Does The Material And Construction Of A Lathe Belt Influence Vibration Levels During Operation?The material and construction of a lathe belt can really change how much it shakes while working. If the belt is made of a strong and flexible material, it can absorb vibrations better. A well-made belt, with a smooth shape, can also help things move evenly. This means less shaking, which makes your work easier and safer.

What Strategies Can Be Employed To Properly Tension A Lathe Belt To Minimize Vibration?To properly tension a lathe belt and reduce vibration, you can start by adjusting the tension with the tensioning screws. Make sure the belt is tight but not too tight; you should be able to press it down slightly. You can also check the belt for any wear or damage and replace it if needed. Lastly, ensure that the pulleys are aligned correctly. This helps the belt run smoothly and keeps things steady!

How Do Replacing Worn Belts On A Metal Lathe Contribute To Vibration Reduction And Overall Machine Performance?When we replace worn belts on a metal lathe, the machine runs smoother. Worn belts can make the machine shake or vibrate. This shaking can lead to mistakes in our work. New belts help everything move better and quicker, making our projects turn out nicer. So, keeping belts fresh helps the machine work well!

What Role Does The Alignment Of Pulleys Play In Reducing Vibration In A Metal Lathe’S Belt Drive System?The alignment of pulleys helps keep the belt straight. When pulleys are lined up well, the belt moves smoothly. This smooth movement means less bumping and shaking. Less bumping means less vibration, which makes the lathe run better. So, keeping pulleys aligned keeps everything calm and steady!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Most Common Causes Of Vibration In Metal Lathes, And How Can They Be Mitigated Through Belt Selection? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibrations in metal lathes can happen for a few reasons. First, if the machine is not level, it can shake. Second, worn-out parts or bad belts can cause problems too. You can help reduce vibrations by choosing the right belt. Use a strong, tight belt that fits well to keep things steady while you work.”}},{“@type”: “Question”,”name”: “How Does The Material And Construction Of A Lathe Belt Influence Vibration Levels During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material and construction of a lathe belt can really change how much it shakes while working. If the belt is made of a strong and flexible material, it can absorb vibrations better. A well-made belt, with a smooth shape, can also help things move evenly. This means less shaking, which makes your work easier and safer.”}},{“@type”: “Question”,”name”: “What Strategies Can Be Employed To Properly Tension A Lathe Belt To Minimize Vibration? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To properly tension a lathe belt and reduce vibration, you can start by adjusting the tension with the tensioning screws. Make sure the belt is tight but not too tight; you should be able to press it down slightly. You can also check the belt for any wear or damage and replace it if needed. Lastly, ensure that the pulleys are aligned correctly. This helps the belt run smoothly and keeps things steady!”}},{“@type”: “Question”,”name”: “How Do Replacing Worn Belts On A Metal Lathe Contribute To Vibration Reduction And Overall Machine Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we replace worn belts on a metal lathe, the machine runs smoother. Worn belts can make the machine shake or vibrate. This shaking can lead to mistakes in our work. New belts help everything move better and quicker, making our projects turn out nicer. So, keeping belts fresh helps the machine work well!”}},{“@type”: “Question”,”name”: “What Role Does The Alignment Of Pulleys Play In Reducing Vibration In A Metal Lathe’S Belt Drive System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The alignment of pulleys helps keep the belt straight. When pulleys are lined up well, the belt moves smoothly. This smooth movement means less bumping and shaking. Less bumping means less vibration, which makes the lathe run better. So, keeping pulleys aligned keeps everything calm and steady!”}}]}