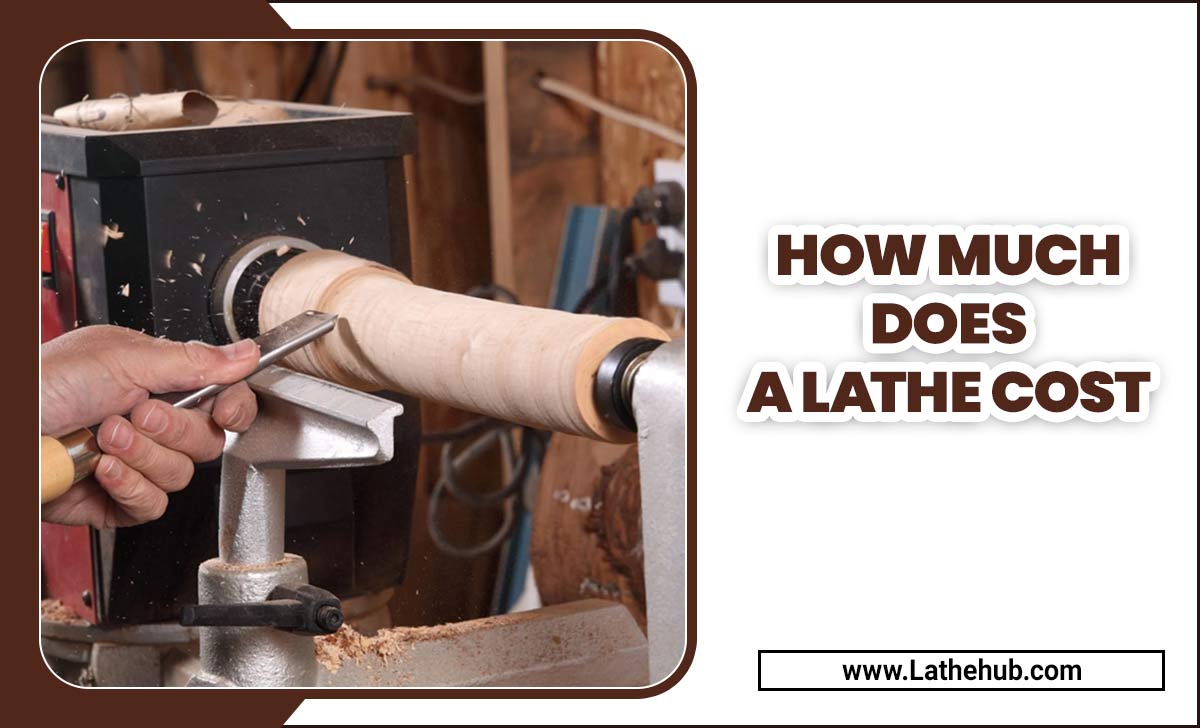

Have you ever watched a metal lathe in action? It spins fast and cuts metal with precision. But sometimes, vibrations can spoil the fun. This is where lathe vibration reduction comes in. It helps keep your machine steady for better work.

Imagine trying to draw a straight line while someone shakes your table. Frustrating, right? That’s how a lathe feels with too much vibration. It can lead to mistakes and wasted time. But what if there was a way to reduce this problem?

In this article, we will explore how a solid metal lathe bench can help. A good bench supports your lathe and keeps it stable. It makes a huge difference in your projects. Let’s dive into the world of lathe vibration reduction and see how you can improve your workspace!

Lathe Vibration Reduction For A Metal Lathe Bench Setup

Lathe Vibration Reduction: Metal Lathe Bench

Lathe vibration can spoil your metalworking projects. A strong bench is key to cutting down those annoying shakes. Using sturdy materials for your lathe bench can help absorb vibrations. Adding rubber pads or dampers can also make a big difference! Did you know that even small changes can lead to smoother cuts? By investing time in reducing vibration, your work becomes safer and more precise. Your projects will thank you for it!Understanding Lathe Vibration

Definition and causes of lathe vibrations. Types of vibrations encountered in metal lathes.Lathe vibrations happen when the machine shakes during use. These vibrations can come from different sources, such as worn parts, incorrect speeds, or poor setup. Troubles with the machine can cause two main types of vibrations:

- Free vibrations: Occur naturally and stop when the machine is off.

- Forced vibrations: Happen due to specific operations and can continue while the machine is running.

Understanding these vibrations helps improve the metal lathe’s performance and create smoother, safer work. Solving vibration issues can lead to better results and longer equipment life.

What causes lathe vibrations?

The main causes of lathe vibrations include worn bearings, misalignment, and tool chatter. These factors can make the lathe shake more than usual, impacting the quality of work.

Common causes of lathe vibrations:

- Incorrect cutting speeds

- Poorly balanced tools

- Loose components

Impact of Vibration on Machining Accuracy

Effects on precision and surface finish. Consequences of prolonged vibration on machine components.Vibrations from machines can hurt the way they work. They affect precision and surface finish. This means that the parts made might not fit well or look good. Over time, constant vibrations can also damage machine parts. This can lead to big problems and costly repairs. Here are some effects:

- Poor cuts that aren’t straight.

- Rough surfaces that need more work.

- Shorter life for machine parts.

In the long run, protecting against vibrations helps keep machines run smoothly and accurately.

How does vibration affect machining?

Vibration can reduce the accuracy of machining. It can lead to poor-quality parts and increased wear on machines.

Techniques for Vibration Reduction

Isolation methods: decoupling and damping. Using vibrationabsorbing materials.Reducing vibration on a lathe is like putting on a comfy pair of socks; it makes everything smoother! One way to do this is through decoupling, which means separating the machine from the surface it sits on. Think of it as placing your blender on a soft mat. Another technique involves damping, which uses materials that absorb vibrations, making your metal lathe feel much quieter and stable.

| Technique | Description |

|---|---|

| Decoupling | Separating machine from its base to reduce noise. |

| Damping | Using special materials to soak up vibrations. |

These tricks can help turn your machine into a purring cat instead of a roaring lion. By using vibration-absorbing materials, you can say goodbye to those pesky shakes and wobbles!

Proper Lathe Setup and Maintenance

Importance of level bench positioning. Regular maintenance checks to prevent vibration issues.A flat and stable bench is very important for using a lathe. If the bench is not level, the lathe can vibrate. This can cause problems when you work. Regular checks help to keep the lathe in good shape. The less vibration, the better your projects will turn out!

- Check the level of the bench frequently.

- Look for any loose parts.

- Oil moving parts regularly.

- Adjust any parts that seem off.

Why is regular maintenance important?

Neglecting maintenance leads to issues like vibrations. This can ruin your work and even damage the lathe. Keeping a schedule for checks is key for lasting use.

Upgrading Lathe Components

Replacement parts to minimize vibrations. Benefits of modern vibrationdampening technologies.Upgrading parts of your lathe can help reduce unwanted vibrations. Newer replacement parts are designed to absorb shock. This makes your metal lathe run smoother. Vibration dampening technologies offer many benefits. They lead to better surfaces on your projects and lower wear and tear. This means your tools last longer and work better.

- Improved accuracy in machining

- Less noise during operation

- Longer equipment lifespan

Why upgrade lathe components?

Upgrading components helps create a quieter, more efficient workspace. A stable lathe ensures better results and happier users. It’s an investment that pays off in quality and performance.

Real-World Case Studies

Success stories of effective vibration reduction strategies. Comparative analysis of beforeandafter scenarios.In various workshops, success stories highlight how reducing vibration changed the game. One shop reported a 30% drop in defects after installing proper vibration dampening tools. Imagine that! The same lathe was wobbling like a jelly on a skateboard before. After treatment, it cut smoothly, like butter.

| Before Vibration Reduction | After Vibration Reduction |

|---|---|

| High defect rates | 30% lower defect rates |

| Machine wear and tear | Less wear on machines |

| Unstable finishes | Smooth, stable finishes |

Real numbers speak louder than words, right? With a bit of strategy and some clever equipment, workshops experienced wonders. It’s not just about saving money; it’s about saving time, too. Vibration reduction is a superhero for any metal lathe bench!

Tools and Equipment for Measuring Vibration

Recommended vibration measurement tools. How to interpret vibration data for adjustments.There are many tools for measuring vibration. Here are some recommended ones:

- Vibration Meter: This handheld device shows how much vibration occurs.

- Accelerometer: It detects tiny changes in speed and movement.

- Laser Displacement Sensor: This uses light to measure distance and can spot vibrations.

To understand vibration data, look for patterns. If vibrations are high, adjustments are needed. Small changes can make a big difference in performance. Keep your lathe running smoothly!

What are effective ways to measure vibration?

Using vibration meters, accelerometers, and laser sensors can effectively measure vibrations. These tools help you spot problems early and keep your machine working well.

Expert Tips for Continuous Vibration Management

Best practices for ongoing monitoring. Training and guidance for operators on vibration issues.To keep vibration in check, regular monitoring is key. You can use simple tools to measure vibrations, like your phone, if it has a suitable app. This can help catch problems early. Training operators is also important. If they understand vibration issues, they’re less likely to cause chaos. Think of it like a dance; without proper steps, you’ll trip! So, teach them to recognize signs of trouble.

| Best Practices | Training Tips |

|---|---|

| Use vibration sensors regularly | Host monthly workshops |

| Check machine alignment | Provide hands-on demos |

| Review maintenance logs | Share fun facts about vibrations |

Conclusion

In summary, reducing lathe vibration on a metal lathe bench makes your work smoother and more accurate. You can achieve this by using better materials, adjusting machine settings, and maintaining your equipment. Try different methods to find what works best for you. For more tips or tools, keep exploring resources and learning about vibration reduction in metalworking!FAQs

What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Identified?Metal lathes can shake for a few reasons. One cause is if the tool is not balanced. You might also feel vibrations if the lathe isn’t sitting on a sturdy surface. Loose parts can cause noise too. To find the problem, check for loose screws and make sure everything is tight and in place.

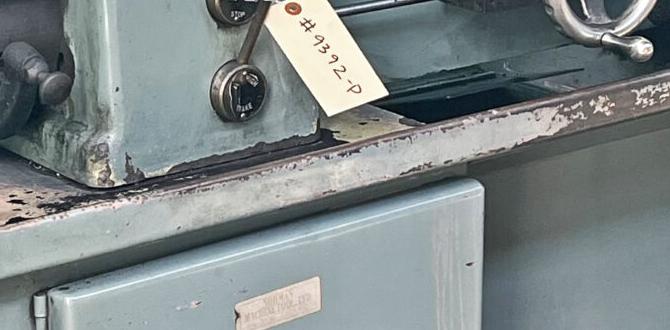

What Materials Or Techniques Can Be Used To Construct A Vibration-Dampening Bench For A Metal Lathe?To build a vibration-dampening bench for a metal lathe, use heavy materials like thick wood or metal. You can also add soft rubber feet under the bench to absorb shakes. Another idea is to fill the inside of the bench with sand or gravel for extra weight. This helps keep the lathe steady when you use it. Lastly, make sure the bench is very sturdy so it doesn’t wobble.

How Does The Weight And Stability Of A Lathe Bench Impact The Performance Of A Metal Lathe During Operation?The weight and stability of a lathe bench are really important. A heavy bench won’t move or shake when we use the lathe. This helps the machine work better and makes smoother cuts. If the bench is light or wobbly, it can mess up our work. So, a strong and stable bench helps us make better metal parts.

What Role Do Dampening Pads Or Isolation Mounts Play In Reducing Vibrations In Metal Lathe Setups?Dampening pads and isolation mounts help stop vibrations from a metal lathe. They sit between the machine and the floor. When the lathe works, these pads absorb the bumps and shakes. This keeps the lathe steady and helps it make better cuts. With less vibration, you can do your job more easily and safely.

How Can Routine Maintenance And Proper Alignment Of A Metal Lathe Contribute To Minimizing Vibrations On Its Bench?Taking care of a metal lathe helps it work better. When you keep it clean and check its parts, it runs smoothly. Proper alignment keeps everything straight, which helps prevent wobbles. Less wobbling means less vibration on the bench, making it easier to use. By doing this, you can make your work more precise and safe.