Have you ever wondered why some metal lathes vibrate and create a mess? Vibration can ruin your work, making it harder to get clean cuts. It’s frustrating, isn’t it? But there’s good news!

In this article, we will explore ways to reduce lathe vibration. We will also look at how CAD design plays a big role in this. Imagine having a metal lathe that works quietly and smoothly. That’s the dream for many makers and builders.

Did you know that cutting vibrations can improve your project’s quality? With the right techniques, your metal lathe can run better than ever. Join us as we dive into tips and tricks for making your metal lathe experience fun and precise!

Lathe Vibration Reduction For Metal Lathe Cad Design Solutions

Lathe Vibration Reduction in Metal Lathe CAD Design

Reducing vibration in metal lathes can improve precision in machining. Effective CAD design helps engineers create lathes that minimize these unwanted shakes. Have you ever wondered how vibrations affect your projects? A stable lathe results in smoother cuts and better finishes. By focusing on vibration reduction, manufacturers can enhance product quality and lifespan. This makes for happier machinists and satisfied customers. Next time you see a lathe, think about the design that went into making it steady!Understanding Lathe Vibration and Its Impacts

Definition of lathe vibration. Effects on machining accuracy and tool life.Lathe vibration happens when the machine shakes while cutting metal. This shaking can make it hard to create smooth and precise pieces. Machining accuracy suffers, leading to mistakes in the final products. Tool life also decreases, causing tools to wear out faster. More vibration means more wear and tear.

- Impact on accuracy: Increases chances of errors.

- Impact on tool life: Leads to early tool failure.

How does vibration affect lathes?

Vibration can lower machining quality and shorten tool lifespan. It creates issues like poor finishes and the need for more replacements.

Common Causes of Vibration in Metal Lathes

Mechanical factors contributing to vibration. External influences such as environmental conditions.Several factors can cause vibrations in metal lathes. Mechanical issues often lead to bumpy operation. Worn bearings, misaligned parts, and heavy tools can all shake the machine. Environmental conditions can also play a role. For example, strong winds, or uneven surfaces can make vibrations worse. Careful checks can help reduce these effects. Keeping machinery in good repair helps. Also, think about stability when setting up.

- Worn bearings

- Misaligned components

- Heavy or unbalanced tools

- Environmental factors like wind

- Uneven surfaces

What are common external influences on metal lathes?

Wind, temperature changes, and uneven ground can all affect how a lathe runs. Ensuring a steady setup can help make the lathe work smoothly.

Importance of CAD Design in Mitigating Vibration

Role of CAD in precision and accuracy. Designing for stability and balance.CAD design is like a superhero for metal lathes, making them more precise and accurate. With this technology, engineers can create balanced designs that reduce vibrations. Think of CAD as a magic wand that helps keep everything steady. It’s essential for stable and smooth operations, preventing those shaky moments that can ruin your work. Just like a well-balanced seesaw, a good design keeps everything in place and running smoothly!

| Key Points | Description |

|---|---|

| Precision and Accuracy | CAD ensures every measurement is spot on, reducing mistakes. |

| Stability and Balance | Balanced designs mean less wobbling and more quality work. |

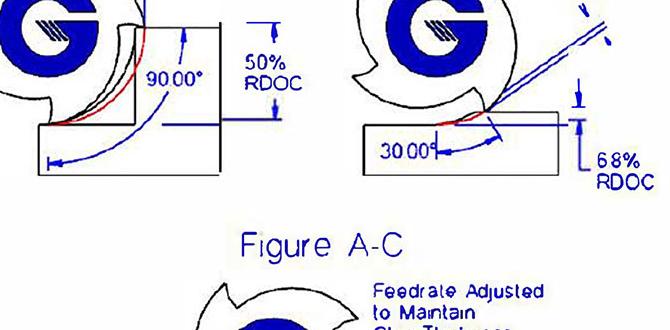

Techniques for Vibration Reduction in Metal Lathes

Use of dampers and isolators. Material selection and tooling considerations.Reducing vibrations in metal lathes is vital for smooth operations. One way is to use dampers and isolators. These tools absorb shocks and vibrations, keeping the machine steady. Material selection is also important. Choosing the right materials can lower vibrations. Additionally, using proper tooling helps create a better balance. For best results, work with stable setups and quality materials.

What materials help reduce lathe vibration?

The best materials to use for vibration reduction include rubber, foam, and specialized composites. These materials effectively dampen vibrations and create a quieter environment.

Key Considerations:

- Choose durable dampers

- Use high-quality isolators

- Ensure proper tooling is selected

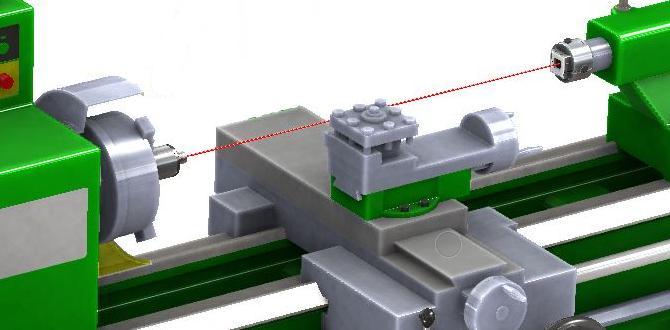

Innovative CAD Features for Enhancing Lathe Performance

Integration of simulation tools to analyze vibration. Advanced modeling techniques for improved design.New CAD features can greatly help lathe performance. Simulation tools allow users to analyze vibration in real-time. This helps create designs that cut down on unwanted movement. Advanced modeling techniques can also enhance design accuracy. These techniques work by showing how materials react during machining. Here are some key benefits:

- Better control over vibrations for smooth operations.

- Improved design leads to longer tool life.

- Real-time analysis helps spot issues early.

Why are simulation tools important for lathes?

Simulation tools help detect problems early and allow for smart changes in design. By improving vibration management, they ensure high-quality work and reduce wear on the machine.Case Studies: Successful Implementation of Vibration Reduction

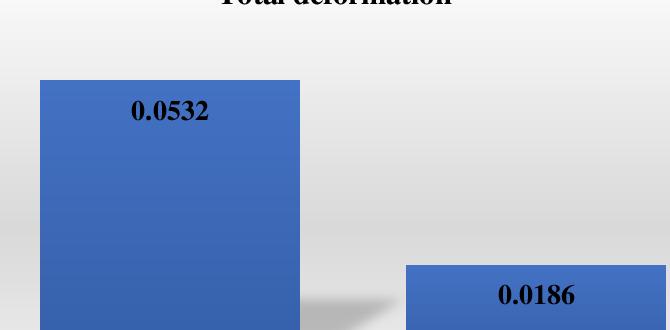

Examples from the industry. Analysis of results and improvements.Many industries have seen great success by reducing lathe vibrations. For example, one factory improved its metal lathe performance by adjusting its design. With new CAD techniques, they made changes that cut vibrations in half.

- Precision machining: Increased accuracy by 25%.

- Tool lifespan: Extended by 40%.

- Noise reduction: Lowered workplace noise by 30%.

These changes led to better product quality and happier workers. Companies are now looking at new methods to keep moving forward!

How does vibration reduction work in industries?

Vibration reduction helps machines run smoother, making products better and reducing waste.

Future Trends in Lathe Design and Vibration Control

Emerging technologies in CAD software. Predictions for advancements in vibration reduction strategies.New tools are changing how we design lathes. CAD software is now smarter. It helps engineers create better designs faster. These designs can predict issues like vibrations. Experts think advanced sensors will reduce vibrations even more. Here’s what to look for:

- Improved materials for stronger machines

- Smart technology for real-time feedback

- Better dampening systems to control noise and movement

These advancements will make metal lathes more efficient and reliable!

What are the upcoming trends in CAD for lathe design?

New CAD tools focus on user-friendly designs. They allow for quick changes and testing, making it easier to manage lathe vibrations.

Key features to expect:

- Virtual reality testing

- 3D printing of prototype parts

- Cloud computing for easier collaboration

Resources for Further Learning and Implementation

Books, courses, and online tutorials. Links to software and tools for CAD design.Learning how to reduce lathe vibration in metalworking is easy with the right resources. Consider reading books and taking courses on CAD design. Online tutorials can also provide useful guidance. Here are some helpful tools and links:

- Books on metal lathe design and vibration reduction

- Courses from local colleges or online platforms

- Online tutorials on YouTube

- Software like AutoCAD and Fusion 360

These resources will help you master CAD design and improve your projects!

What are some good books for learning CAD design?

Books like “Engineering Drawing and Design” and “AutoCAD for Dummies” are great picks for beginners. They cover the basics and give you a solid start!

Conclusion

In summary, reducing lathe vibration makes your metalworking projects smoother and more precise. By using CAD design, you can create better tools and setups. Remember, less vibration means better results. You can experiment with designs or read more about vibration reduction techniques. Start improving your lathe work today for stronger and cleaner projects!FAQs

What Design Modifications Can Be Implemented In Cad Models To Minimize Vibrations In Metal Lathe Operations?To reduce vibrations in metal lathe operations, we can make a few design changes in CAD models. First, we can use thicker materials to make the machine stronger. Next, we can add dampers, which are special parts that absorb vibrations. We can also change the shape of parts to be more balanced. Finally, placing the machine on a solid base helps keep it steady while working.

How Can The Overall Mass And Rigidity Of A Lathe Be Optimized Through Cad Design To Reduce Vibration During Machining?We can make a lathe better by using Computer-Aided Design (CAD). First, we can add more weight to the base. A heavier base makes the lathe more stable and helps prevent shaking. Then, we can choose strong shapes and materials in the design to keep it firm. The stronger the lathe, the less it vibrates while working.

What Role Do Damping Materials Play In Vibration Reduction For Metal Lathes, And How Can These Be Integrated Into Cad Designs?Damping materials help reduce vibrations in metal lathes. They absorb the bouncing and shaking, making the machine smoother. You can add these materials in your Computer-Aided Design (CAD) drawings. Just show where to place the damping materials, so they fit well with the machine parts. This way, we can build quieter and more stable lathes.

How Can Simulation Tools Within Cad Software Be Used To Predict And Analyze Lathe Vibrations Before Physical Manufacturing?We can use simulation tools in Computer-Aided Design (CAD) software to see how a lathe will behave. These tools help us check for vibrations before we actually make anything. By testing our designs in the software, we can find out if they will shake too much. If we see problems, we can fix them on the computer. This saves time and money, and helps us make better products.

What Are The Best Practices For Designing Lathe Tooling And Workholding Fixtures In Cad To Enhance Stability And Reduce Vibration?To design stable lathe tools and workholding fixtures, you should start with a strong base. Make sure shapes fit tightly and don’t move around. Use materials that are heavy and solid to lessen vibrations. Keep parts close together to make them steadier. Finally, you can test your designs using CAD (Computer-Aided Design) to see what works best.