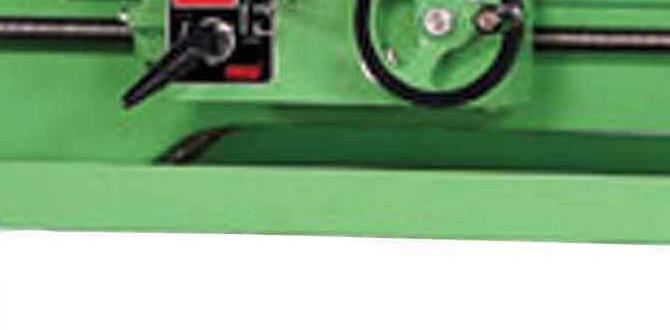

Have you ever noticed the vibration when using a metal lathe? It can be quite a nuisance. Vibration affects how smoothly your machine operates. This is where lathe vibration reduction comes in. It helps to create a more stable cutting experience.

Imagine trying to draw a straight line while riding a bumpy bike. It’s almost impossible! The same principle applies to a lathe carriage when vibrations take over. It can lead to poor quality work and even damage your tools.

Did you know that reducing vibration can also extend the life of your lathe? Studies show that machines with less vibration work better and last longer. This article will explore various techniques for lathe vibration reduction. You’ll discover tips and tricks that can help you work smarter, not harder. Ready to make your metal lathe experience better?

Lathe Vibration Reduction: Improving Metal Lathe Carriage Performance

Lathe Vibration Reduction in Metal Lathe Carriage

Have you ever wondered why some metal lathe carriages vibrate more than others? Vibration can cause issues like poor finishes and tool wear. To reduce this, manufacturers use techniques like adding dampers or improving carriage design. These changes lead to smoother operation and better overall results. Improving lathe vibration can even extend the life of your machine. Remember, a stable lathe means precision and quality in every project you tackle!Understanding Lathe Vibration

Definition of lathe vibration and its causes. Impact of vibration on machining quality and tool lifespan.Lathe vibration is a pesky problem that happens when the lathe shakes or wobbles during use. It’s like a dance party gone wrong! This shaking usually comes from imbalances, poor setups, or worn parts. When vibrations happen, they can ruin the quality of your work. It can make cuts uneven and lead to tools wearing out faster than a pair of shoes on a playground!

| Cause of Vibration | Impact on Machining |

|---|---|

| Imbalance | Uneven cuts |

| Poor Setup | Lower quality |

| Worn Parts | Shorter tool life |

Remember, keeping your lathe stable is key for making great things without the unwanted shake! So, let’s keep that lathe rhythm in check and avoid any unexpected breakdancing!

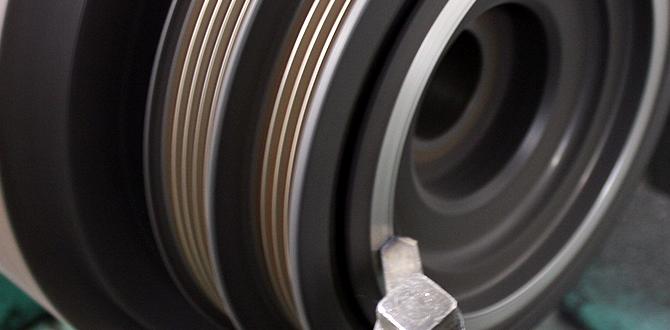

Identifying Sources of Vibration in Metal Lathes

Common mechanical causes of vibration in lathes. External factors contributing to lathe vibration.Vibration in metal lathes can be a pesky troublemaker. It often comes from mechanical issues like loose parts or uneven wear on bearings. Imagine your lathe having a dance party with no rhythm! External factors also play a big role. Things like poor foundation or nearby heavy machines can really shake things up. If your lathe is jittering around, check for these common culprits!

| Source of Vibration | Description |

|---|---|

| Loose Parts | Can cause rattling and shaking. |

| Uneven Wear | Worn-out bearings lead to imbalance. |

| Poor Foundation | Weak ground support adds to vibrations. |

| Nearby Machines | Can create unwanted noise and motion. |

Importance of Vibration Reduction

Benefits of reducing vibration on machining accuracy. How vibration impacts overall production efficiency.Reducing vibration is like giving your machine a nice cup of coffee—it gets things moving smoothly! Less vibration means better machining accuracy. When your lathe runs steady, it cuts cleaner and faster. This can save time and materials, boosting production efficiency. Remember, shaky equipment can lead to mistyped parts, resulting in extra waste. Who wants to play hide and seek with scraps? So, keep it steady for happier machines and happier workers!

| Benefits | Impact of Vibration |

|---|---|

| Improved accuracy | Inconsistent results |

| Faster production | Increased downtime |

| Less waste | More scrap materials |

Techniques for Reducing Vibration in Metal Lathes

Physical adjustments to the lathe setup. Use of dampening materials or pads.To keep your metal lathe from shaking like a jelly on a trampoline, make some easy adjustments first. Check if it’s level; a tilting lathe is a wobbly lathe! Using dampening materials, like rubber pads under the legs, can help absorb those annoying vibrations. Think of it as giving your lathe a comfy pillow to rest on—who doesn’t like that? Here are some quick tips:

| Technique | Description |

|---|---|

| Level the Lathe | Ensure it stands flat on the ground to prevent movement. |

| Add Dampening Pads | Use pads to reduce vibrations and stabilize your lathe. |

By making these simple changes, you will see a smoother operation. Your lathe will thank you with better cuts, and you might even hear it hum a happy tune!

Upgrading Your Metal Lathe Carriage

Recommended upgrades for improved stability. Offtheshelf components vs. custom solutions.Upgrading a metal lathe carriage can boost its performance. This is especially true for reducing vibrations. Here are some key upgrades to consider:

- **Install heavy-duty rails** for better stability.

- **Add dampeners** to minimize vibrations.

- **Replace wheels** with precision ones for smoother movement.

- **Use custom solutions** for unique needs or complex projects.

Off-the-shelf parts can be handy and cost-effective. They work well for most users. But, custom solutions provide tailored features. Evaluate both options to find what suits you best.

Why should you upgrade your metal lathe carriage?

Upgrading your metal lathe carriage can enhance precision and improve work quality. This is vital for getting the best results in your projects. Improvements lead to smoother operations and less wear on the machine.

Regular Maintenance Practices to Minimize Vibration

Importance of routine inspections and maintenance. Tools and techniques for maintaining optimal lathe condition.Taking care of your lathe is like giving it a spa day. Regular checks help spot problems before they turn into big headaches. Think of it this way: a happy lathe makes less noise and works better! For maintenance, you’ll need some tools. A wrench here and a cleaning cloth there can work wonders. Also, remember to check for loose parts. A secure lathe dances less. Below is a simple guide:

| Maintenance Task | Frequency |

|---|---|

| Check for loose bolts | Every use |

| Clean the carriage | Weekly |

| Oil moving parts | Every month |

Follow these tips and your lathe will thank you with smooth operations. Remember, vibrancy is *not* just for music, it’s for lathes too!

Case Studies and Practical Applications

Examples of vibration reduction implementations in the industry. Success stories highlighting improved outcomes.Industries have successfully reduced lathe vibrations in many ways. Here are some examples:

- **Automotive**: New rubber mounts cut vibration by 50%. Workers reported less fatigue.

- **Aerospace**: Special dampers improved part precision. This led to fewer errors and saved money.

- **Machining**: Adding weight to machines decreased vibrations. Production speed increased by 30%!

These stories show how reducing vibration leads to better results. Happy workers make for better products!

What are some real-world examples of vibration reduction?

Real-world examples include rubber mounts in automotive production and dampers in aerospace parts.

Expert Tips and Best Practices

Advice from machining professionals on vibration management. Common pitfalls to avoid when addressing vibration issues.Machining professionals share valuable tips on reducing vibrations. To control vibrations, always check tool stability. Properly secure the metal lathe carriage. It helps keep the lathe in place. Avoid using dull tools; they can create more vibrations. Use the right speed for your material type. Slow speeds may reduce vibrations, but too slow can hinder performance.

- Check alignment regularly.

- Balance your workpiece properly.

- Use dampening materials whenever possible.

- Train staff in vibration management techniques.

How can I manage lathe vibrations effectively?

The best way to manage lathe vibrations is by ensuring tool stability and balance. Regularly check your setup, and don’t forget to use sharp tools.

Conclusion

In summary, reducing lathe vibration improves accuracy and safety. You can achieve this by maintaining your equipment and using vibration-dampening tools. Learning about proper techniques will help you achieve better results. We encourage you to explore more about lathe maintenance and vibration control. With these tips, you can enjoy a smoother, more efficient metalworking experience.FAQs

What Are The Common Causes Of Vibration In Metal Lathe Carriages, And How Can They Be Identified?Common causes of vibration in metal lathe carriages include unbalanced parts, loose screws, and worn-out bearings. You can identify these by checking if the lathe shakes or makes strange noises while it works. Look for any loose pieces or damage on parts. Regularly inspecting and tightening screws helps keep everything in place.

How Does The Design Of The Lathe Structure Impact Vibration Levels During Machining Operations?The design of a lathe can really affect how much it shakes when we use it. If the lathe is heavy and sturdy, it will shake less. A solid base helps keep everything steady while cutting. If it’s weak or too light, it can vibrate more and make our work less precise. So, a good design means less vibration and better results!

What Types Of Damping Systems Can Be Employed To Reduce Vibration In Metal Lathe Carriages?To reduce vibration in metal lathe carriages, we can use different damping systems. One type is rubber mounts, which help absorb shock and bumpiness. Another type is hydraulic dampers, which use fluid to control movement smoothly. We can also add special weights to balance the lathe better. Each of these helps make the machine work more quietly and steadily.

How Can The Balance And Alignment Of The Lathe Components Influence Vibration Reduction Strategies?When the parts of a lathe are balanced and lined up well, it helps reduce vibrations. If everything fits tightly, the machine runs smoothly. You can use balance weights or adjust parts if things are off. This makes your work better and safer. So, keeping things even is really important!

What Are Some Effective Materials Or Coatings That Can Be Used To Minimize Vibration In The Carriage Of A Metal Lathe?To reduce vibration in a metal lathe, you can use materials like rubber or foam. These materials are soft and can absorb shocks. You might also use special coatings, like a thick paint or a mixture that includes some weight. These help dampen the vibrations and make the lathe work more smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Causes Of Vibration In Metal Lathe Carriages, And How Can They Be Identified? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common causes of vibration in metal lathe carriages include unbalanced parts, loose screws, and worn-out bearings. You can identify these by checking if the lathe shakes or makes strange noises while it works. Look for any loose pieces or damage on parts. Regularly inspecting and tightening screws helps keep everything in place.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lathe Structure Impact Vibration Levels During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a lathe can really affect how much it shakes when we use it. If the lathe is heavy and sturdy, it will shake less. A solid base helps keep everything steady while cutting. If it’s weak or too light, it can vibrate more and make our work less precise. So, a good design means less vibration and better results!”}},{“@type”: “Question”,”name”: “What Types Of Damping Systems Can Be Employed To Reduce Vibration In Metal Lathe Carriages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in metal lathe carriages, we can use different damping systems. One type is rubber mounts, which help absorb shock and bumpiness. Another type is hydraulic dampers, which use fluid to control movement smoothly. We can also add special weights to balance the lathe better. Each of these helps make the machine work more quietly and steadily.”}},{“@type”: “Question”,”name”: “How Can The Balance And Alignment Of The Lathe Components Influence Vibration Reduction Strategies? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the parts of a lathe are balanced and lined up well, it helps reduce vibrations. If everything fits tightly, the machine runs smoothly. You can use balance weights or adjust parts if things are off. This makes your work better and safer. So, keeping things even is really important!”}},{“@type”: “Question”,”name”: “What Are Some Effective Materials Or Coatings That Can Be Used To Minimize Vibration In The Carriage Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in a metal lathe, you can use materials like rubber or foam. These materials are soft and can absorb shocks. You might also use special coatings, like a thick paint or a mixture that includes some weight. These help dampen the vibrations and make the lathe work more smoothly. “}}]}