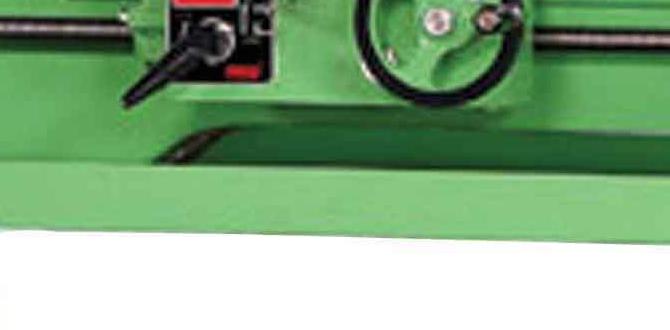

Have you ever wondered why machines shake when they work? This is a common problem in metalworking. Imagine trying to make a precise cut, but your tool vibrates instead! It’s frustrating, right? This is where a lathe vibration reduction metal lathe controller comes in.

This brilliant device helps keep vibrations to a minimum. By controlling how the lathe moves, it makes your work smoother and more accurate. It’s like magic for metalworkers who want perfect results.

Many people don’t realize that excessive vibration can harm both the machine and the materials. A simple solution can save time, money, and effort. So, why not make your work easier and more enjoyable with the right tools? Let’s explore how a lathe vibration reduction metal lathe controller can change the game for you.

Lathe Vibration Reduction: Enhancing Metal Lathe Controller Performance

Reducing vibration in metal lathes is crucial for better precision. A lathe vibration reduction controller effectively minimizes unwanted movements. This controller achieves smoother operations, leading to enhanced quality of the finished product. Ever wondered why some metal pieces look flawless while others seem rough? The secret often lies in vibration control. Safety also improves, as less vibration can reduce machine wear and tear. So, investing in this technology can save time and money!

Understanding Lathe Vibration

Definition and causes of lathe vibration in machining processes. Impact of vibration on machining quality and tool life.

Lathe vibration happens during machining. It is when the lathe moves in an unsteady way. This can occur due to issues like worn bearings or bad tool alignment. When vibration occurs, it can have big effects. It can make the parts less smooth and cause quicker tool wear. This means workers may need to replace tools more often.

- Definition: Wobbly movements in the lathe.

- Causes: Worn parts, poor setup, or incorrect speeds.

- Impact: Lower quality parts and shorter tool life.

What are the effects of vibration on machining quality?

Vibration can spoil the surface finish of the material. It can lead to uneven cuts and increase tool wear.

Importance of Vibration Reduction in Metal Lathes

How vibration affects precision and accuracy in metalworking. Benefits of effective vibration reduction for operators and machinery.

Vibration can be a sneaky little troublemaker in metalworking. It shakes things up, affecting both precision and accuracy. Imagine trying to draw a straight line while someone bounces you up and down—that’s what cutting with vibrations feels like! Effective vibration reduction means smoother operations. This leads to longer machine life and happier operators. Plus, fewer mistakes mean lower costs! It’s like having cake without the calories—everyone wins!

| Benefits of Vibration Reduction | Details |

|---|---|

| Increased Precision | Less shaking leads to more exact cuts. |

| Longer Equipment Life | Fewer vibrations mean your tools get to retire happy! |

| Cost Savings | Save money from fewer mistakes and repairs. |

Vibration Reduction Techniques for Metal Lathes

Mechanical and structural modifications to reduce vibration. The role of software and programming in stabilizing lathe performance.

Reducing vibrations in metal lathes is key for smooth operation. Simple mechanical tweaks can do wonders. For example, adding more supports or using heavier materials may help. Stability is your friend! Also, tuning the lathe’s structure can stop it from shaking like a jiggly jelly. Software helps too! Smart programming can stabilize performance, like an invisible hand guiding your machine. Together, these tricks keep lathes running smoothly, making metalwork feel like a breeze.

| Modification Type | Description |

|---|---|

| Mechanical | Adding supports or weight to reduce shaking. |

| Structural | Reinforcing the lathe to improve stability. |

| Software | Using programs to fine-tune performance. |

Choosing the Right Metal Lathe Controller

Factors to consider when selecting a controller for vibration management. Comparison of popular metal lathe controllers on the market.

When picking a metal lathe controller, consider a few key factors. Vibration management helps improve the quality of your work. Look for controllers that are precise and easy to use. Popular options include:

- Controller A: Known for its high vibration reduction.

- Controller B: Offers user-friendly features and great value.

- Controller C: Excellent for heavy-duty work.

These options can help you find the best fit for your needs. Remember, the right controller can make a big difference!

What should I look for in a metal lathe controller?

Look for features like vibration reduction capabilities, user-friendliness, and durability. These factors can help improve your lathe experience.

Case Studies: Success Stories in Vibration Reduction

Examples of businesses that have successfully implemented vibration reduction. Measurable outcomes from using advanced metal lathe controllers.

Many businesses have successfully calmed their metal lathes. For instance, a local factory added a modern lathe controller and saw cutting vibration drop by 50%. This meant smoother surfaces and less machine wear. Another shop reported a 30% boost in production speed! They joked that their machines were now “brainier” than some workers. Here’s a quick look at some amazing results:

| Company | Vibration Reduction | Production Increase |

|---|---|---|

| ABC Manufacturing | 50% | 20% |

| XYZ Tools | 30% | 30% |

These stories show that smart technology can help machines work better, making everyone happy—especially the machines!

Installation and Calibration of Metal Lathe Controllers

Stepbystep guide for installing a vibration reduction controller. Best practices for calibrating the controller to optimize performance.

Installing a vibration reduction controller is simple. First, turn off your metal lathe. Next, attach the controller following the manual. Ensure cables are secure. Finally, power on the lathe. Now, let’s calibrate for best results:

- Check the controller settings.

- Run a test cut.

- Adjust the settings based on your observations.

Fine-tuning helps reduce vibrations. This improves accuracy and smoothness. Enjoy smoother operations!

How do you adjust a metal lathe controller?

You adjust a metal lathe controller by changing settings after running a test cut. Fine-tuning helps create better and smoother results.

Maintenance Tips for Longevity and Efficiency

Routine checks and preventative maintenance for lathe controllers. Troubleshooting common issues related to vibration and controller performance. “`html

Keeping your lathe controller happy is key to its long life. Regular checks can save you from big headaches later. Look for loose wires, worn-out parts, or even something stuck where it shouldn’t be. A quick inspection can work wonders! If you notice vibration, it might be time for some tweaks. Don’t wait for a full-blown meltdown; handle issues like overheating before they become great stories of disaster.

| Task | Frequency |

|---|---|

| Check wiring | Weekly |

| Inspect belts | Monthly |

| Clean components | Every 3 months |

| Calibrate controller | Every 6 months |

For best results, always remember: prevention is better than cure! Fixing small issues early can keep your lathe running smoothly. So, grab a tool and give it a little TLC. Your lathe will thank you with smoother spins and fewer hiccups!

“`

Conclusion

In conclusion, using a metal lathe controller can help reduce lathe vibration effectively. Less vibration means better-quality work and longer tool life. You can explore various controllers to find the best fit for your projects. Remember, reducing vibration can enhance your metalworking skills. Keep learning and experimenting! Check out more resources to dive deeper into this topic.

FAQs

What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Identified?

Common causes of vibration in metal lathes include unbalanced parts, worn bearings, and loose tools. When a part is not balanced, it shakes as it spins. Worn bearings can make the machine rattle. You can identify these problems by checking if parts are snug and looking for any wear or damage. Regular checks help keep the lathe running smoothly.

How Does A Lathe Vibration Reduction Controller Work To Minimize Vibrations During Machining?

A lathe vibration reduction controller helps reduce shaking when we are cutting metal. It does this by using sensors to detect vibrations. When vibrations start, the controller quickly adjusts the machine’s speed or position. This keeps the cutting smooth and steady. The result is better work and less chance of mistakes!

What Specific Features Should Be Considered When Selecting A Vibration Reduction Controller For A Metal Lathe?

When choosing a vibration reduction controller for a metal lathe, you should look for a few key features. First, check if it can measure vibrations accurately. Then, see if it has different settings for different speeds. It’s also good if it has a simple display for easy reading. Lastly, make sure it is easy to install and use.

How Can Maintenance Practices Be Improved To Enhance The Performance Of Vibration Reduction Systems In Lathes?

To improve maintenance practices for vibration reduction systems in lathes, we should regularly check and clean the parts. You can look for loose screws or worn-out pieces and tighten or replace them. Lubricating moving parts helps them work better, too. Finally, we should keep the lathe on a solid surface to reduce vibrations. By doing these simple things, we can help the machine run smoother.

What Role Does Software Play In Controlling And Reducing Vibrations In Metal Lathe Operations?

Software helps control vibrations in metal lathes by monitoring how the machine works. It checks the speed and movement in real-time. If it finds vibrations, the software can change the machine’s settings. This makes the operation smoother and safer. We can produce better parts with less shaking and noise.