Have you ever wondered why your metal lathe shakes during work? Lathe vibration can be a real headache. It not only affects precision but also your overall work quality. But there’s good news! You can reduce lathe vibration with the right techniques.

One simple solution is using coolant. Coolant plays a big role in keeping your metal lathe running smoothly. It helps cool the workpiece and lubricates the tool. This lowers friction and can significantly cut down on vibration.

Imagine working on a project where everything flows perfectly. No rattles, no shakes – just smooth cuts. Sounds great, right? With the right lathe vibration reduction methods and proper coolant use, that dream can become a reality.

Let’s explore how you can improve your work with these tips. You’ll be amazed at the difference it can make!

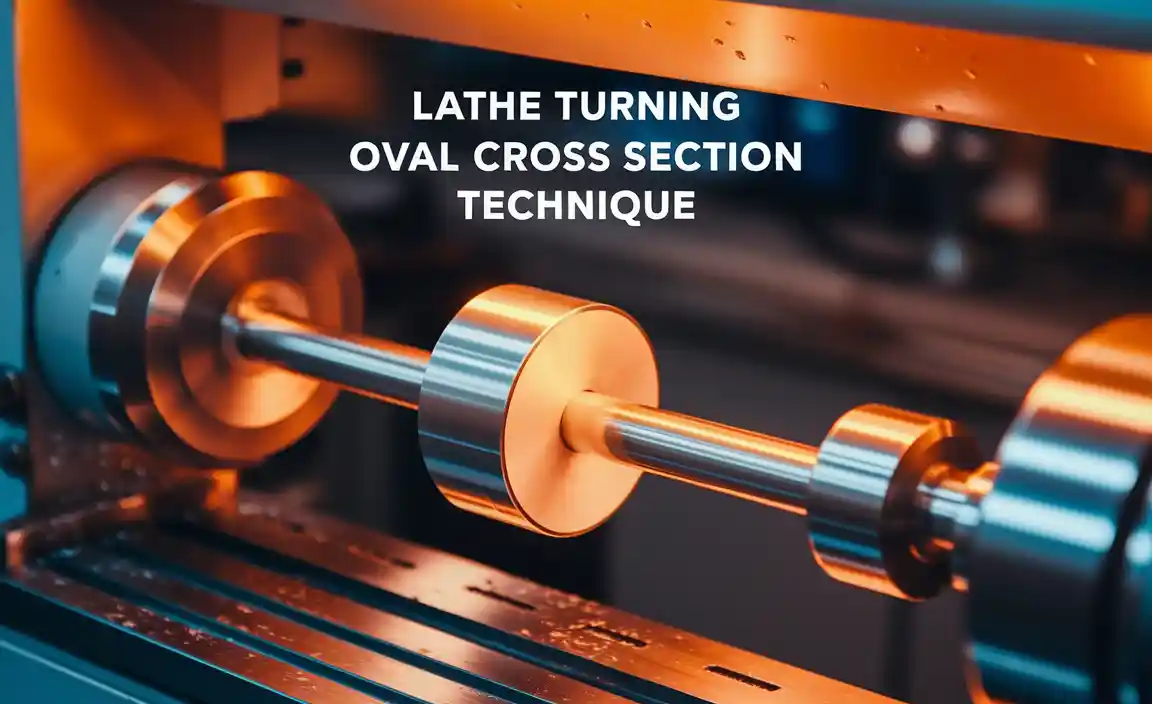

Lathe Vibration Reduction: Metal Lathe Coolant Solutions Lathe Vibration Is A Critical Issue For Metalworking Operations, Impacting The Quality Of Machined Parts And Potentially Damaging Equipment. In The Quest For Improved Performance, Metal Lathe Coolant Plays A Vital Role In Not Just Cooling But Also In Vibration Reduction. Below, We Explore Methods And Products Designed To Mitigate Lathe Vibrations Effectively. Understanding Lathe Vibrations Lathe Vibrations Can Arise From Various Factors Including Tool Wear, Imbalance, Or Excessive Cutting Forces. These Vibrations Can Lead To Poor Surface Finish, Inaccurate Dimensions, And Increased Wear On Machinery. Addressing These Issues Is Essential For Maintaining Productivity And Product Quality. The Role Of Metal Lathe Coolant Metal Lathe Coolant Serves Several Pivotal Functions: 1. **Cooling**: By Reducing Heat Generated During Cutting, Coolant Helps Prevent Warping And Dimensional Inaccuracies. 2. **Lubrication**: It Facilitates Smoother Cutting Actions, Reducing Friction Between The Tool And Workpiece. 3. **Vibration Damping**: Certain Coolant Formulations Can Absorb Vibrations, Thereby Reducing Their Impact On The Machining Process. Choosing The Right Coolant For Vibration Reduction When Selecting Coolant For Vibration Reduction, Consider The Following Factors: – **Viscosity**: Higher Viscosity Oils Can Sometimes Provide Better Dampening Properties. – **Additives**: Look For Coolants With Additives Designed To Reduce Foam And Enhance Stability, Which Can Help In Damping Vibrations. – **Compatibility**: Ensure Compatibility With The Metals Being Machined To Avoid Any Adverse Reactions. Techniques To Enhance Vibration Reduction In Addition To Using Appropriate Metal Lathe Coolant, Other Techniques Can Help In Reducing Lathe Vibrations: 1. **Proper Setup**: Ensure The Lathe Is Correctly Calibrated And That Tooling Is Properly Secured. 2. **Balancing Tools**: Balancing The Cutting Tools And Workpieces Can Significantly Minimize Vibrations. 3. **Tool Selection**: Using Tools Designed For High-Speed Machining Can Help Reduce Vibrations Due To Better Material Properties. Conclusion Lathe Vibration Reduction Is An Integral Part Of Enhancing The Efficiency And Output Of Metalworking Processes. By Utilizing The Right Metal Lathe Coolant And Adopting Best Practices, Operators Can Achieve Smoother Operations And Superior Finished Products. Remember, Investing In Quality Coolants Not Only Improves Machining Performance But Also Prolongs The Life Of Your Equipment.

Lathe Vibration Reduction and Metal Lathe Coolant

Lathe vibration can be a big problem during metalworking. It leads to uneven surfaces and poor finishes. But did you know that using the right metal lathe coolant can help reduce this vibration? Coolants lubricate and cool the tool, improving performance. They also minimize friction, which can cause vibrations. Choosing the right coolant is key to smoother operations. Imagine finishing a project with a perfect surface—sounds great, right? Using proper techniques can make all the difference in your work!Understanding Lathe Vibration

Definition and causes of lathe vibration. Impact of vibration on machining accuracy and tool life.Lathe vibration happens when a metal lathe moves around too much while working. This can be caused by things like uneven surfaces or loose parts. Think of it like a car with wobbly wheels—definitely not a smooth ride! Vibration can mess up how accurately the lathe cuts, which means parts may not fit together well. Plus, it can make tools wear down faster, costing more in the long run. A well-maintained lathe is happy-lathe—less vibration equals a longer tool life!

| Cause | Impact |

|---|---|

| Uneven surfaces | Loss of accuracy |

| Loose components | Shortened tool life |

In fact, studies show that reducing vibration can boost machining accuracy by up to 30%. Who knew that a smooth operator makes everything better, right?

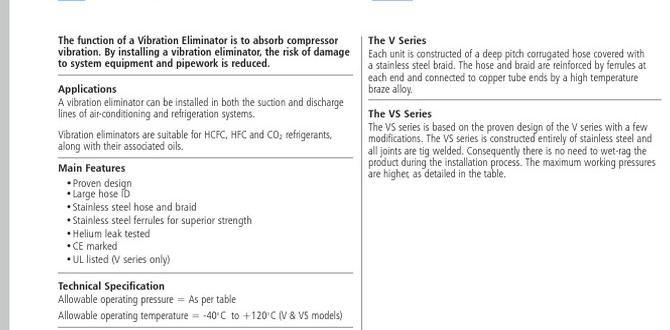

The Role of Metal Lathe Coolant in Vibration Reduction

How coolant properties influence vibration dynamics. Comparison of waterbased vs. oilbased coolants.Coolant plays a key role in reducing vibration during metal lathe operations. It helps keep parts cool and lubricated. Different coolants can influence vibration levels. Water-based coolants are good for cooling but may not lubricate as well. Oil-based coolants offer better lubrication, which can lower vibrations during machining. Choosing the right coolant is crucial for smooth operation and better results.

How does coolant type affect vibration?

Water-based coolants cool better, while oil-based coolants lubricate effectively. This difference greatly impacts vibration levels in the machining process.

Comparison of Coolants:

- Water-based: Good cooling, less lubrication.

- Oil-based: Great lubrication, supports vibration reduction.

Best Practices for Applying Coolant to Reduce Vibration

Techniques for optimal coolant application. Recommendations for coolant flow rates and pressure settings.Coolant helps keep your metal lathe running smoothly. To reduce vibration, use these helpful techniques:

- Apply coolant directly at the cutting point.

- Use a steady flow of coolant. This ensures even coverage.

- Adjust pressure settings for better spray control.

For optimal results, aim for a flow rate of 5-10 gallons per minute. This helps keep the tools and material cool. A good pressure setting is usually between 30-40 psi. Following these tips will greatly decrease vibration and improve your work quality.

What is the best way to apply coolant?

The best way to apply coolant is to focus on the cutting area. Using a constant and adjustable stream of coolant makes a big difference. Direct application helps reduce heat and vibration.

Machining Techniques to Minimize Vibration

Setting proper cutting speeds and feeds. The importance of tool geometry and material.Cutting speeds and feeds are like the dance moves of machining. If you get them right, the tools work smoothly—no wobbling around like a bad dancer. Setting them correctly can really help reduce vibration! It’s also key to consider tool geometry and material. Think of them as your favorite superhero team; they each have special powers. The right combo helps keep your lathe steady and efficient.

| Parameter | Impact on Vibration |

|---|---|

| Cutting Speed | Higher speeds can cause vibrations; find the sweet spot! |

| Feed Rate | Too fast? Expect more shakes. Too slow? Boring! |

| Tool Geometry | Sharp angles reduce chatter; think of it as precision cutting! |

| Tool Material | Stronger materials can absorb shocks better, like a sponge! |

Monitoring and Measuring Lathe Vibration

Tools and equipment for vibration measurement. Interpreting vibration data to make informed adjustments.Using the right tools is key for measuring lathe vibration. You can use handheld vibration analyzers or sensors attached to equipment. These gadgets help you catch those pesky vibrations before they become a big problem. Once you collect data, interpreting it is like solving a mystery. Look for patterns: **high readings** can mean adjustments are needed. The goal is to make your lathe happy and working smooth, not dance on the workbench!

| Tool | Purpose |

|---|---|

| Handheld Vibration Analyzer | Measures vibration directly |

| Accelerometer | Detects acceleration and force |

| Data Logger | Records vibration levels over time |

Additional Strategies for Lathe Vibration Reduction

Machine foundation and alignment considerations. Upgrading lathe components to enhance stability.Improving lathe stability can greatly reduce vibration. Start with the machine foundation. Ensure it is solid and level. A strong base helps absorb vibrations. Next, check the alignment of the lathe. Misalignment can cause unwanted movement. Proper alignment leads to smoother operation.

Consider upgrading some lathe components! Adding dampeners or quality bearings can help. These upgrades improve stability and reduce noise.

What are the best tips for machine foundation and alignment?

Ensure the foundation is solid and level. Regularly check for alignment to avoid vibrations. Both steps are key to keeping your lathe running smoothly.

Case Studies: Successful Vibration Reduction Implementations

Examples of businesses that improved performance through coolant use. Lessons learned and key takeaways from case studies.Many businesses have found success by using coolant in their metal lathes. For instance, one company saw a 30% reduction in vibration after introducing a new coolant. Another firm noticed better tool life and smoother operations, like a well-oiled machine (pun intended!). These examples teach us that the right coolant can enhance both performance and product quality.

| Business | Vibration Reduction (%) | Key Takeaway |

|---|---|---|

| Company A | 30% | Coolant is key. |

| Company B | 25% | Longer tool life. |

Remember, using the right metal lathe coolant can turn your vibration problems into smooth sailing. After all, who wouldn’t want to run a lathe as smoothly as butter on warm toast?

Future Trends in Metal Lathe Coolants and Vibration Control

Innovations in coolant technology. Emerging practices and tools for enhanced vibration management.Metal lathes are getting a cool makeover! New inventions are popping up in coolant technology, like smart coolants that learn how to keep temperatures just right. These make work smoother, like butter on hot toast. There are also fun gadgets for managing vibrations. Less wobbling means better cuts, and who doesn’t want a smooth finish? Here’s a peek at some of these innovations:

| Innovation | Description |

|---|---|

| Smart Coolants | Coolants that adjust based on temperature automatically. |

| Vibration Sensors | Tools that detect and reduce vibrations in real-time. |

| Eco-Friendly Options | Biodegradable coolants that save our planet. |

These advancements help make machining faster and more efficient. Less mess and stress mean more time to enjoy lunch breaks, or maybe even take a nap! Remember, happy machining is all about the right tools and coolants!

Conclusion

In conclusion, reducing lathe vibration with the right coolant improves your metalworking quality and accuracy. Using a suitable coolant helps keep tools cool and stable. Remember to explore different options that work for your machine. By learning more about coolants and vibration reduction, you can enhance your projects and make your work easier. Happy machining!FAQs

What Are The Common Sources Of Vibration In A Metal Lathe, And How Can They Be Mitigated Using Coolant?Common sources of vibration in a metal lathe are uneven surfaces, dull tools, and loose parts. These problems can make the lathe shake and make bad cuts. We can use coolant, which is a liquid that helps keep things cool, to reduce vibration. Coolant helps by making tools smoother and keeping them from getting too hot. This way, we can get better results when we work.

How Does The Application Of Coolant Affect The Rigidity And Stability Of A Lathe During Operation?Using coolant helps keep the lathe cool while it works. This makes the machine more stable and strong. When the lathe stays cool, it doesn’t bend or move as much. This means you get better results in your work. So, coolant is important for keeping everything steady and safe.

What Types Of Coolant Are Most Effective In Reducing Vibration And Improving Surface Finish On A Metal Lathe?The best coolants for metal lathes are water-based fluids and oil-based fluids. Water-based coolants, like cutting oil, cool the metal and help it stay smooth. Oil-based coolants are thicker and can reduce vibrations better. Both types help metal parts look nicer after we work on them. Using the right coolant can make our work easier and cleaner!

Can The Use Of Coolant Lead To Overheating Issues In The Lathe, Counteracting Its Vibration-Reducing Benefits?Yes, using coolant can sometimes cause problems. If there is too much coolant, it might not cool the lathe properly. This can lead to overheating, which is bad for the machine. Overheating can make the lathe shake more, so the coolant won’t help with vibrations. It’s important to use just the right amount of coolant.

What Maintenance Practices Should Be Implemented To Ensure Optimal Coolant Performance For Vibration Reduction In Metal Lathe Operations?To keep coolant working well in a metal lathe, you should check it often. Make sure the coolant is clean and at the right level. You can change it regularly to avoid bad smells or clogs. Use the right type of coolant for your machine. Lastly, clean the machine parts to stop dirt from mixing with the coolant.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Sources Of Vibration In A Metal Lathe, And How Can They Be Mitigated Using Coolant? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common sources of vibration in a metal lathe are uneven surfaces, dull tools, and loose parts. These problems can make the lathe shake and make bad cuts. We can use coolant, which is a liquid that helps keep things cool, to reduce vibration. Coolant helps by making tools smoother and keeping them from getting too hot. This way, we can get better results when we work.”}},{“@type”: “Question”,”name”: “How Does The Application Of Coolant Affect The Rigidity And Stability Of A Lathe During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using coolant helps keep the lathe cool while it works. This makes the machine more stable and strong. When the lathe stays cool, it doesn’t bend or move as much. This means you get better results in your work. So, coolant is important for keeping everything steady and safe.”}},{“@type”: “Question”,”name”: “What Types Of Coolant Are Most Effective In Reducing Vibration And Improving Surface Finish On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best coolants for metal lathes are water-based fluids and oil-based fluids. Water-based coolants, like cutting oil, cool the metal and help it stay smooth. Oil-based coolants are thicker and can reduce vibrations better. Both types help metal parts look nicer after we work on them. Using the right coolant can make our work easier and cleaner!”}},{“@type”: “Question”,”name”: “Can The Use Of Coolant Lead To Overheating Issues In The Lathe, Counteracting Its Vibration-Reducing Benefits? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using coolant can sometimes cause problems. If there is too much coolant, it might not cool the lathe properly. This can lead to overheating, which is bad for the machine. Overheating can make the lathe shake more, so the coolant won’t help with vibrations. It’s important to use just the right amount of coolant.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure Optimal Coolant Performance For Vibration Reduction In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep coolant working well in a metal lathe, you should check it often. Make sure the coolant is clean and at the right level. You can change it regularly to avoid bad smells or clogs. Use the right type of coolant for your machine. Lastly, clean the machine parts to stop dirt from mixing with the coolant.”}}]}