Have you ever wondered how some metal lathes work so smoothly while others shake and vibrate? It can be frustrating to deal with lathe vibration, especially for beginners. This article will introduce you to lathe vibration reduction techniques that can make a big difference in your projects.

Imagine trying to create a perfect piece of metal. You are excited and focused. Suddenly, your lathe starts to rattle. It disrupts your work and can ruin your creation. This is a common problem. However, learning how to reduce the vibrations can help you achieve better results.

Did you know that even small changes can improve your metal lathe’s performance? From adjusting the speed to adding dampers, these simple tips can help you work with confidence. Let’s explore the world of lathe vibration reduction, making it easier for you to enjoy your metalworking journey.

Lathe Vibration Reduction: Metal Lathe For Beginners

Lathe Vibration Reduction for Beginners

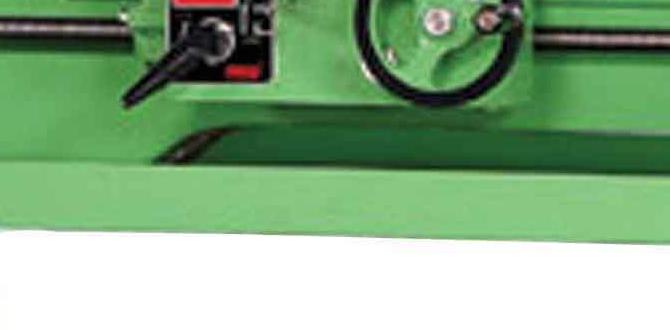

Lathe vibration can make your projects frustrating. For beginners, reducing these vibrations is crucial for smooth operations. You’ll learn about setting up your lathe correctly, using dampening materials, and choosing the right tools. Did you know that a well-adjusted lathe can improve the quality of your work drastically? Discover tips to minimize shaking and create precise metal parts. Mastering these techniques will make your crafting journey enjoyable and rewarding.Understanding Lathe Vibration

Definition and causes of lathe vibration. Importance of reducing vibration for metalworking quality.Lathe vibration is like a loud party crasher during your metalworking project. It makes your tool dance when it should be steady. Vibration can happen due to unbalanced parts, loose bolts, or even the speed of the machine. Reducing this unwelcome shake is key for achieving smooth cuts and a neat finish. If you want your metal pieces to shine like a star, keeping vibration low is a must. Haphazard results are a recipe for disaster—kind of like trying to bake a cake with a jackhammer!

| Causes of Lathe Vibration | Impact on Quality |

|---|---|

| Unbalanced components | Causes rough surfaces |

| Loose connections | Leads to inaccuracies |

| Excessive speed | Increases wear and tear |

Common Sources of Vibration in Metal Lathes

Mechanical issues contributing to vibration. External factors affecting lathe stability.Vibration in metal lathes can really rattle your results! Common mechanical issues like loose bolts and worn bearings can cause a shaky ride. External factors like uneven floors or too much coffee for the operator? Well, they can shake things up too! It’s like trying to balance a spoon on your nose while riding a bike. Let’s break it down with a simple table:

| Source of Vibration | Description |

|---|---|

| Loose Components | Parts that aren’t tight enough can wiggle around. |

| Worn Bearings | Old bearings make for a rough day at work! |

| Uneven Floors | A bumpy floor makes for a bumpy lathe! |

| Operator Fatigue | Too much coffee can lead to a shaky hand! |

Tackling these factors can help you achieve smooth sailing—or should I say smooth turning—on your lathe!

Impact of Vibration on Metalworking Projects

Effects on material finish and precision. Longterm implications for machine wear and tear.Vibration can hurt metalworking projects in several ways. First, it can affect the material finish. This means surfaces may not look smooth and clean. Second, vibration can lead to lower precision. Parts may not fit together as they should. Over time, vibration also causes wear and tear on machines. This can lead to costly repairs and a shorter lifespan. Keeping machines steady helps ensure great results.

How does vibration affect metalworking projects?

The effects of vibration include:

- Rough surfaces: Vibration can create uneven finishes.

- Inaccurate cuts: It may lead to poor fitting parts.

- Machine damage: Long-term exposure can ruin equipment.

Vibration Reduction Techniques for Beginners

Adjustment methods for lathe setup. The role of proper tool selection and maintenance.To reduce vibrations while using a lathe, start by adjusting the setup. Make sure everything is tight and balanced. This helps keep the lathe steady while working. Choosing the right tools is also key. Sharp and clean tools cut better and create less vibration. Regular maintenance helps too. A well-kept lathe runs smoother and lasts longer.

How can I make my lathe smoother?

To make your lathe smoother, ensure it is well adjusted and that you select quality tools.Quick Tips:

- Keep the lathe level.

- Check for loose parts.

- Use sharp tools.

- Regularly clean the machine.

Utilizing Vibration Dampening Materials

Types of materials for vibration reduction. Installation tips for effective dampening.Vibration dampening is important for a smooth lathe experience. Different materials can help reduce vibrations. Some effective types include:

- Rubber pads – These absorb shock well.

- Foam strips – Lightweight and easy to install.

- Mass loaded vinyl – Good for heavy-duty needs.

When installing, make sure to:

- Clean the surface before adding materials.

- Leave no gaps for the best results.

- Test by running the lathe at slow speeds first.

Using these tips can make your metal lathe quieter and safer. It’s all about having a smooth ride!

What materials can help reduce lathe vibrations?

Common materials include rubber pads, foam strips, and mass loaded vinyl. They effectively absorb shock and vibrations.

Advanced Techniques for Experienced Users

Balancing and alignment methods. Custom modifications to enhance stability.Fine-tuning your lathe is a bit like tuning a musical instrument. Proper balancing and alignment can make a huge difference. Start by checking the legs of the lathe; they should all touch the ground. Use a level to see if it’s straight. You can even make custom modifications, like adding weight or anti-vibration pads. These tricks keep the machine stable and singing smoothly, just like your favorite song—minus the off-key notes!

| Technique | Description |

|---|---|

| Balancing | Ensure all parts are even to prevent wobbling. |

| Alignment | Use a level to keep the lathe straight. |

| Custom Mods | Add weights or vibration pads to improve stability. |

With these advanced techniques, your lathe will be as steady as a rock—and maybe even dance a little! So get ready to create some smooth shapes.

Safety Precautions When Dealing with Vibration

Personal protective equipment (PPE) considerations. Best practices for a safe working environment.Working with machines can be exciting but also a bit wobbly at times. To keep safe, you need the right Personal Protective Equipment (PPE). Think hard hats, safety glasses, and earplugs! They make you look cool while saving your noggin. Set up your workspace wisely. Keep tools organized and cords tucked away. Trip hazards are not good friends. Remember, a clean space makes for a happy place!

| PPE Items | Purpose |

|---|---|

| Hard Hats | Protects your head from falling objects. |

| Safety Glasses | Shields your eyes from flying debris. |

| Earplugs | Prevents hearing loss from loud machines. |

Always remember, safety first! You can’t work on your lathe if you’re sidelined by a mishap. Follow these tips, and your metal lathe experience will be as smooth as butter on toast!

Resources for Further Learning

Books and online courses on lathe operation and maintenance. Community forums and support groups for metalworking enthusiasts.Learning about metal lathes doesn’t stop after you start using one. Many helpful resources can guide you along the way. Consider reading some books about lathe operation and maintenance. Online courses can also teach you new skills at your own pace. Join community forums and support groups filled with other metalworking fans. They often share tips and experiences. These resources can make your journey easier and more enjoyable.

What are some good resources for learning about metal lathes?

Books, online courses, and community forums are great resources for learning. They provide valuable information and support from others with similar interests.

Here are some ideas:

- Books on lathe techniques

- Online video tutorials

- Discussion groups for metalworkers

Conclusion

In summary, reducing lathe vibration is crucial for better results with metal lathes. You can improve accuracy and finish by checking tools and setup. Remember to balance and maintain your lathe for smoother operation. We encourage you to practice these tips and explore more about lathe techniques. Happy machining!FAQs

What Are The Common Causes Of Vibration In A Metal Lathe, And How Can Beginners Identify Them?Common causes of vibration in a metal lathe include loose parts, worn-out tools, and uneven workpieces. You can check if parts are tight by giving them a little shake. If the tool looks damaged or dull, it’s time to replace it. Make sure the piece you’re working on is balanced. If the machine shakes a lot, stop and check these things.

How Can Beginners Effectively Adjust The Spindle Speed To Reduce Vibration During Machining?To reduce vibration, you should start by checking the machine’s spindle speed. You can change the speed by turning a dial or pressing some buttons. If you hear a lot of noise or shaking, slow the speed down a bit. Sometimes, a lower speed helps your machine run smoother. Always test and listen carefully as you adjust!

What Types Of Vibration-Dampening Accessories Or Modifications Are Recommended For Novice Metal Lathe Users?If you’re starting with a metal lathe, using vibration-dampening pads is a great idea. These pads go under the lathe to absorb bumps and shakes. You can also add weights to the base for more stability. Another helpful option is using rubber feet on the legs. These simple changes can make your work easier and better!

How Does The Setup And Alignment Of A Metal Lathe Impact Vibration Levels, And What Steps Can Beginners Take To Ensure Proper Setup?The setup and alignment of a metal lathe can affect how much it shakes while you work. If the lathe isn’t level or straight, it may vibrate more. To avoid this, you should check that the lathe sits on a stable surface. Make sure the parts line up perfectly and tighten all the screws. Taking these steps helps the lathe run smoothly and keeps the vibrations low.

What Materials And Techniques Can Beginners Use To Create A Stable Work Environment That Minimizes Lathe Vibration?To reduce lathe vibration, you can use heavy materials like concrete or thick wood for the workbench. Make sure your lathe is level and securely attached. Use rubber pads under the legs to absorb some shaking. Keep the area clean and organized to prevent accidents and distractions. Lastly, always check your tools to ensure they fit properly and are not loose.