Have you ever watched a metal lathe in action? The whirring sound can be mesmerizing, but have you noticed the vibrations? Lathe vibration can be a big problem. It may lead to inaccurate cuts and ruined workpieces. But what if there was a simple solution? By focusing on vibration reduction, you can achieve better results with your metal lathe.

Using a sturdy handwheel is a game changer. It gives you more control and steadiness. Imagine being able to shape metal easily without those annoying shakes! With the right tools and techniques, this can be your reality.

Did you know that even small changes can make a huge difference? By learning how to reduce lathe vibrations, you can enjoy smoother operation and improved precision. You’ll make better projects and feel more confident as you work. Get ready to explore the world of lathe vibration reduction!

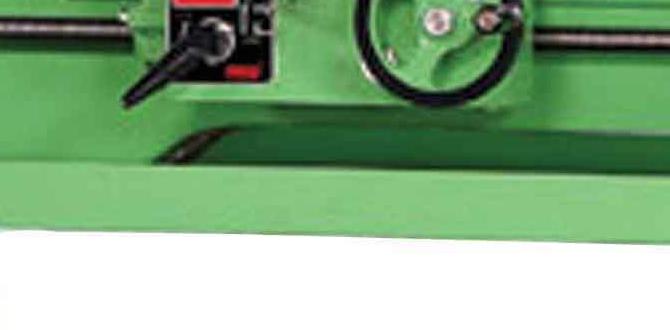

Lathe Vibration Reduction: Enhancing Metal Lathe Handwheel Performance

Lathe Vibration Reduction Metal Lathe Handwheel

Vibration in metal lathes can be frustrating and lead to poor work quality. A well-designed handwheel helps reduce this vibration. By ensuring smoother operation, it improves precision and safety during use. You’ll learn how effective handwheels enhance stability and control. Did you know that even slight vibrations can affect your final product? Using the right handwheel can be the secret to perfect machining results. It’s a simple upgrade that makes a big difference!Understanding Lathe Vibration

Definition and causes of lathe vibration. Impact of vibration on machining precision and surface finish.Lathe vibration is an unwanted shaking that happens while using a lathe machine. It can occur due to different reasons, like uneven surfaces or loose parts. This vibration affects the tools and materials used in machining. It can lead to poor precision in shaping and make the surface look rough. Here’s how vibration impacts your work:

- Reduces precision: Vibration makes it hard to get accurate cuts.

- Affects surface finish: The finished product may not look smooth.

Understanding these factors is essential for better results and safer work.

How does vibration affect lathe machining?

Lathe vibrations can lead to inaccuracies in measurements and poor quality in the final product. They cause frustration for machinists and can result in wasted time and materials.

Importance of Vibration Reduction in Metal Turning

Effects of vibration on tool wear and life. Consequences of vibration on workpiece quality.Vibration can harm tools and workpieces in metal turning. When tools vibrate, they wear down faster. This means they need to be replaced more often. More vibrations can also ruin the quality of the piece you are working on. High vibrations lead to poor finishes, making it harder to meet quality standards.

- Tool Wear: Increased vibration leads to quicker tool wear.

- Workpiece Quality: Vibration causes rough surfaces and inaccurate shapes.

How does vibration affect tools and workpieces?

Vibration reduces tool life and lowers the quality of the finished part. This can make your projects take longer and cost more. Keeping vibrations low is very important in metal turning.

Factors Contributing to Lathe Vibration

Machine design and structural integrity. Tool selection and cutting parameters.Several factors can make a lathe vibrate. First, the machine’s design must be strong. If it’s not, vibrations can get worse. Good parts keep everything steady. Second, choosing the right tools matters. If the tool is wrong, it can cause extra shakes. Finally, cutting at the right speed is key. Going too fast can create more vibrations. Combining these elements will help reduce lathe vibration.

What factors make lathe vibration worse?

Machine design, tool choice, and cutting speed all play a big role. Poor design leads to instability, bad tools cause shaking, and incorrect speeds can increase vibrations.

- Strong machine design

- Correct tool selection

- Optimal cutting parameters

Strategies for Vibration Reduction

Balancing and alignment techniques. Use of vibrationdampening materials and mounts.Vibration can harm metal lathes, but we can reduce it through smart choices. First, proper balancing and alignment are key. They ensure parts work together smoothly without shaking. Next, using vibration-dampening materials helps absorb vibrations. These materials often come as rubber or foam mounts. Together, these techniques keep machines steady and running well.

How can I reduce vibrations in my lathe?

To reduce vibrations, keep the lathe balanced. Make sure all parts align correctly. Use materials like rubber mounts to absorb shocks. This way, your lathe operates quieter and lasts longer.

Case Studies on Handwheel Modifications

Successful implementation of modified handwheels. Results and improvements in vibration reduction.Several users have made changes to their lathe handwheels and seen great success. These new designs help cut down vibrations while working. Here’s what some found:

- Better grip: Modified handwheels allow for easier handling.

- Less noise: Many users report quieter machines.

- Faster work: People can finish jobs quicker without added shakes.

These improvements show how small changes can make big differences in using a lathe more safely and effectively.

What are the key benefits of modified handwheels?

Modified handwheels reduce vibrations, improve operator comfort, and enhance precision in metalworking tasks. This leads to better overall performance and satisfaction.

Choosing the Right Metal Lathe Handwheel

Key specifications to consider. Recommendations for different machining applications.Finding the right handwheel for a metal lathe can feel like searching for a needle in a haystack. Key specs to think about include the size and grip. A comfy handwheel can make your turning much smoother. For hobbyists, a compact wheel works well, while professionals may need a beefier one for tough jobs. Here’s a quick guide:

| Application | Recommended Handwheel Size |

|---|---|

| Hobby Machining | 4-6 inches |

| Heavy-Duty Work | 6-10 inches |

| Precision Tasks | 5-7 inches |

Remember, a great handwheel makes your lathe dance through the metal, rather than stumble like a clumsy toddler!

Future Trends in Lathe Vibration Reduction

Innovations in technology and materials. Predictions for the future of lathe designs and operations.Exciting changes are coming in lathe technology. New materials like carbon fiber and advanced polymers are making lathes lighter and stronger. These innovations will help reduce vibrations even more. Predictive designs are on the rise, allowing lathes to adjust automatically during operations. This will lead to smoother cutting and better results. Imagine a future where lathes work quietly while making perfect shapes.

What are future trends for lathe vibration reduction?

Future trends include smarter designs and better materials. Expect lighter lathes that vibrate less and perform more efficiently.

Key Innovations:

- Use of carbon fiber for stiffness

- Smart sensors for automatic adjustments

- Advanced software for better control

These changes will improve how lathes operate and create more precise products.

Conclusion

In summary, reducing lathe vibration improves precision and makes your work easier. Using a well-designed metal lathe handwheel can help achieve this. Remember to regularly check your equipment for wear and tear. You can also explore online resources for tips on improving your lathe setup. Keep learning, and soon you’ll be creating smoother projects!FAQs

What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Identified And Mitigated?Vibrations in metal lathes can happen for several reasons. First, loose parts can cause rattling. Second, if the machine is not sitting flat, it can shake. Third, unbalanced tools can create bumps. We can find these problems by checking for loose screws, using a level, and ensuring tools are balanced. To fix them, we can tighten parts, adjust the lathe, and use better tools.

How Does The Design And Material Of A Lathe Handwheel Impact Its Contribution To Vibration During Operation?The design and material of a lathe handwheel can change how much it vibrates while working. A heavy handwheel made of solid metal can help reduce vibrations. If the handwheel is too light or made of weak material, it might shake more. Smooth shapes and good balance also help keep vibrations low. This makes using the lathe easier and more comfortable for you.

What Are Some Effective Techniques For Reducing Lathe Vibration Manually, Specifically When Using The Handwheel?To reduce lathe vibration, you can try a few things. First, hold the handwheel steady with both hands. This helps you control the machine better. Next, turn the handwheel slowly and smoothly. Quick or jerky movements can make vibrations worse. Finally, check if the lathe is on a stable surface. If it’s wobbly, fix that first!

How Can Proper Alignment And Balance Of A Lathe Impact Overall Vibration Levels And The Performance Of The Handwheel?When a lathe is properly aligned and balanced, it helps reduce vibrations. Less vibration means the machine runs smoother. This makes it easier for you to use the handwheel. If the lathe isn’t balanced, it can shake, and that makes it hard to control. So, good alignment helps everything work better together!

What Role Do Vibration Dampening Systems Or Accessories Play In Enhancing The Stability And Accuracy Of A Metal Lathe’S Handwheel Operation?Vibration dampening systems help reduce shaking when you use a metal lathe. This makes it easier to turn the handwheel smoothly. When there’s less shake, you get better control and make more accurate cuts. These systems keep everything steady, making your work easier and more precise.