Have you ever watched a metal lathe in action? The whirring and buzzing sounds can be fascinating. Yet, did you know that this powerful tool can sometimes vibrate, making it less effective? Lathe vibration can lead to poor finishes and damaged parts. What if there was a way to reduce that vibration and improve metal lathe operations?

Imagine a world where your lathe runs smoothly without annoying shakes. This isn’t just a dream—it can be a reality! By learning about lathe vibration reduction, you can make your metal lathe work better than ever.

In this article, we will explore simple strategies to minimize lathe vibration. These tips can help anyone who works with metal lathes, whether you’re a hobbyist or a professional. So, let’s dive in and discover how to make your lathe experience smoother and more enjoyable!

Lathe Vibration Reduction For Metal Lathe Operations

Lathe Vibration Reduction in Metal Lathe Operations

Vibration can be a big problem when using a metal lathe. It leads to poor finishes and can even damage the machine. Cutting tools chatter and the workpiece may not turn out right. Did you know that by improving lathe setup and adding dampening materials, you can nearly eliminate this issue? Properly balancing the spindle and using vibration-isolating mounts can also help. These simple steps can improve your metal lathe projects significantly.Understanding Lathe Vibration

Definition of lathe vibration and its causes. Importance of addressing vibration in metal lathe operations.Lathe vibration happens when a metal lathe shakes during operation. It can be caused by many things, like misalignment, unbalanced parts, or even using old tools. Imagine trying to cut cake with a wobbly knife—it’s messy! Addressing vibration is crucial because it helps improve accuracy and the quality of your work. A smooth operation means better results and less risk of damage. Remember, happy machines make happy workers!

| Cause of Vibration | Effect on Operations |

|---|---|

| Misalignment | Inaccurate cuts |

| Unbalanced components | Increased wear |

| Dull tools | Poor surface finish |

Impact of Vibration on Metal Lathe Operations

Effects on machining accuracy and finish quality. Consequences on tool life and production efficiency.Vibration is like a pesky little fly buzzing around while you’re trying to focus. It can mess up the accuracy of your machining job and spoil the finish quality. Imagine trying to cut a pizza while it’s wobbling on the table—what a disaster! Tool life can take a hit, too. Excess vibration wears out tools faster, like a kid on a swing that keeps getting pushed higher. Lastly, it slows down production efficiency, making you feel like you’re running a marathon in slow motion. Keep vibrations in check for smooth sailing!

| Effects | Impact |

|---|---|

| Machining Accuracy | Reduced precision and finish quality. |

| Tool Life | Shortened due to excess wear. |

| Production Efficiency | Slower process and increased costs. |

Common Sources of Lathe Vibration

Mechanical factors: imbalance, misalignment, and wear. External factors: environmental influences and setup mistakes.Lathe vibrations can sneak up on you like a cat on a Windowsill. First, there’s mechanical stuff like imbalance, which happens when parts don’t weigh the same. Next up is misalignment, where things just don’t line up properly. Don’t forget wear and tear; even machines need a spa day! Then there are external factors, like environmental chaos. A windy workshop or uneven floors can shake things up. Lastly, setup mistakes can make your day go downhill fast!

| Source of Vibration | Description |

|---|---|

| Imbalance | Uneven weight distribution in parts. |

| Misalignment | Parts not lined up correctly. |

| Wear | Normal use causing parts to degrade. |

| Environmental Factors | Wind, dust, or uneven surfaces can shake things up. |

| Setup Mistakes | Improper assembly leading to issues. |

Measuring Lathe Vibration

Tools and techniques for vibration analysis. Interpreting vibration data for effective diagnosis.To keep your lathe humming smoothly, it’s important to measure vibration. Use tools like accelerometers and vibration analyzers to catch the wiggles and shakes. These gadgets can pinpoint problems faster than your favorite superhero! Once you collect the data, the real fun begins. Look for patterns in the graphs. If the number spikes like your coffee intake in the morning, it might be time for a tune-up.

| Tool | Purpose |

|---|---|

| Accelerometer | Measures vibration levels |

| Vibration Analyzer | Analyzes vibration data |

Remember, interpreting this data is like reading a map. If it’s messy, you might end up lost! So, always check those readings twice. In the world of lathe vibration, knowledge is power, or at least, it helps you avoid accidental earthquakes in your workshop!

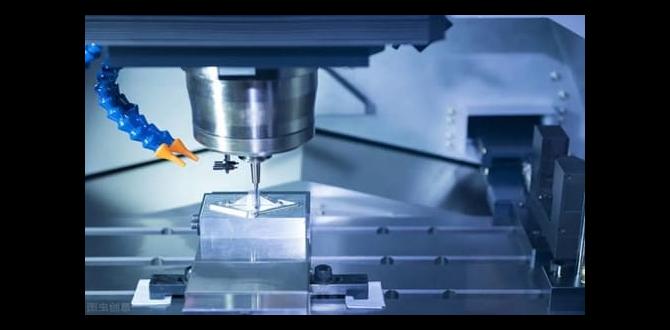

Designing for Vibration Reduction

Selecting materials and tooling for dampening effects. Structural modifications to enhance stability.Choosing the right materials and tools can significantly reduce vibrations during metal lathe operations. A well-crafted tool, like a trusty sidekick, dampens those pesky vibrations. Lightweight materials like aluminum can be efficient, but don’t forget the classic heavyweights like steel for some serious stability.

Sometimes, you need to give your lathe a little makeover. Structural changes can boost stability, making it tougher than a superhero in a rubber suit! Try reinforcing the base and adding dampening pads. Your lathe will thank you and run smoother than a penguin on ice!

| Tool Material | Vibration Reduction Effect |

|---|---|

| Aluminum | Light, quick motion |

| Steel | Heavy, stable |

| Composite | Balanced performance |

In a nutshell, smart choices in materials and clever upgrades can make your lathe as stable as a cat on a sunny windowsill!

Operational Techniques for Minimizing Vibration

Best practices for setup and operation. Optimizing feeds and speeds for vibration control.Keeping your lathe steady is the secret sauce to smooth metalwork. Start by ensuring everything is set up properly. Check that your lathe is on a solid surface. Level it, or it might dance like a clumsy penguin! Optimizing feeds and speeds is equally important. Find the sweet spot: too fast can cause rattles, while too slow may lead to tears. Use the table below for quick references.

| Material | Optimal Speed (RPM) | Feed Rate (IPM) |

|---|---|---|

| Aluminum | 1000-1500 | 2-3 |

| Steel | 500-800 | 0.5-1 |

| Brass | 1500-2000 | 3-4 |

Balancing these factors is key. If you hear too much noise, it might be time to adjust your numbers. Think of it like dancing: if you step on toes, you’ll need to change up your moves!

Maintenance Practices for Reducing Lathe Vibration

Routine checks for wear and damage. Importance of regular alignment and calibration.Keeping a lathe running smoothly is important. You can reduce vibration by regularly checking for wear and damage. This means looking at belts, bearings, and other moving parts. A small issue can cause big problems later. Alignment is also key. If the lathe isn’t aligned properly, it can shake while working. Regular calibration helps to keep everything in place. Remember, a stable machine makes accurate cuts!

Why is maintenance important for lathe vibration?

Maintenance helps to prevent problems and keep your lathe working well. Regular checks and adjustments mean less vibration and better results. Small fixes can save you from larger expenses in the future.

Key Maintenance Tips:

- Check belts for wear.

- Inspect bearings for damage.

- Align the machine regularly.

- Calibrate the settings often.

Case Studies: Successful Vibration Reduction in Metal Lathes

Analysis of realworld examples and solutions implemented. Lessons learned and recommended practices from industry experts.Many companies learned valuable lessons by tackling lathe vibration problems. For example, one factory found that adding rubber mounts cut vibrations in half. Experts say that choosing right materials can make a huge difference. After these changes, productivity soared!

| Case Study | Solution Implemented | Results |

|---|---|---|

| Factory A | Rubber mounts | Vibrations reduced by 50% |

| Shop B | Balanced tools | Improved accuracy and speed |

Experts recommend proper maintenance. Regular checks can save time and cash. Remember, “A well-maintained lathe is a happy lathe!”

Conclusion

In conclusion, reducing lathe vibration is crucial for better metal lathe operations. You can achieve smoother finishes and improve accuracy by using balanced tools and proper setup. Pay attention to maintenance and adjust your machines when needed. Don’t hesitate to explore more tips online to master your lathe skills and enhance your projects!FAQs

What Are The Common Causes Of Vibration In Metal Lathe Operations, And How Can They Be Identified During Machining?Vibration in metal lathe operations can happen for several reasons. First, if the tool is dull, it can shake when cutting. Second, if the metal piece is not secured tightly, it can wobble. Third, if the lathe itself is not balanced, it can cause bumps. You can spot these issues by watching how the machine moves and listening for unusual sounds.

How Can The Design And Setup Of A Metal Lathe Be Optimized To Minimize Vibration During Cutting Operations?To reduce vibrations when using a metal lathe, you can support it on a strong, stable surface. Make sure the lathe is level and tightly secured. Using sharp cutters helps too; they cut through metal smoothly. You can also adjust the speed of the lathe to find a balance that works best. Lastly, adding weight to the base can help keep it steady while you work.

What Role Do Cutting Tools And Tool Material Properties Play In Reducing Vibrational Effects In Lathe Machining?Cutting tools are the parts that do the cutting when we use a lathe machine. The material of these tools can help make smooth cuts. When the tool is strong and sharp, it causes less vibration. Less vibration means better quality work and safer use. So, good tools help us make things better and easier!

How Can Vibration Damping Technologies Or Materials Be Integrated Into Metal Lathe Setups To Improve Machining Stability?We can add special materials, like rubber or foam, to metal lathe setups. These materials help to absorb vibrations while we work. We can also use special tools that soak up the bumps and shakes. This makes the metal cutting smoother and keeps the pieces stable. When we reduce vibrations, our work turns out better and lasts longer.

What Are Some Best Practices For Monitoring And Controlling Vibrations In Metal Lathe Operations To Enhance Product Quality And Tool Life?To reduce vibrations in metal lathe work, we can follow a few simple steps. First, always make sure the lathe is properly set up and balanced. Next, use sharp tools because dull ones can cause more shaking. We should also keep the machine clean and well-oiled. Finally, watch the speed and feed rates; going too fast can cause more vibrations. By doing these things, we can make better products and help our tools last longer!