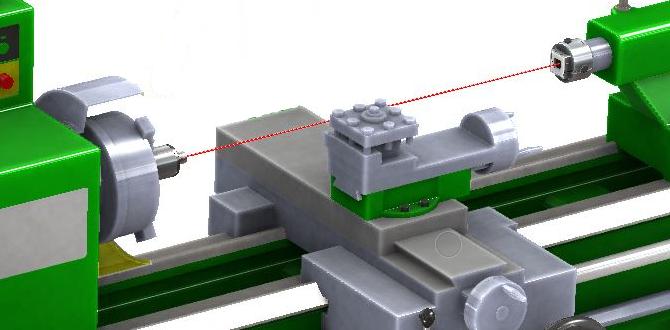

Lathe Vibration Reduction Using Metal Lathe Pulley Solutions

Lathe Vibration Reduction Metal Lathe Pulley

Lathe vibration reduction focuses on improving metal working. Using a specialized lathe pulley can significantly lower vibrations. Less vibration helps create smoother finishes in your projects. Imagine trying to carve a perfect bowl. Too much vibration makes it tough to achieve smooth edges. Did you know that with the right pulley setup, you can work more efficiently? Choosing quality components can elevate your crafting experience and boost overall precision.Understanding Lathe Vibrations

Explanation of lathe vibration causes. Impact of vibrations on machining accuracy and tool life.Lathe vibrations can shake up your work like a coffee enthusiast at a quiet library. These vibrations often come from unbalanced parts, improper setup, or worn-out components. When lathe tools vibrate, the results can be messy. They reduce machining accuracy and can shorten tool life. A worn tool might feel like trying to cut a steak with a butter knife! Keeping things steady is key for smooth work and happy projects.

| Cause of Vibration | Impact on Machining | Impact on Tool Life |

|---|---|---|

| Unbalanced Parts | Lower accuracy | Shorter tool life |

| Improper Setup | Inconsistent cuts | Faster wear |

| Worn Components | Dimensions off | Frequent replacements |

Factors Influencing Lathe Vibration

Material and design of the lathe pulley. Spindle speed and its relation to vibration.Several factors can affect lathe vibration. The material and design of the lathe pulley play key roles. Strong materials help reduce vibration. A well-designed pulley can absorb shocks better.

Another factor is spindle speed. Higher speeds often lead to more vibration. Finding the right spindle speed is important. It can help create smoother work.

What materials reduce lathe vibration?

Strong materials like steel or aluminum often work best. They can lower vibration more than weaker materials.

Key factors include:

- Material strength

- Design quality

- Spindle speed

Understanding these factors can greatly improve your lathe’s performance. Remember, every detail counts!

Effective Pulley Design for Vibration Reduction

Importance of pulley weight and material. Optimization of pulley shape and size.Using the right weight and material for a pulley is very important. Heavier pulleys can help reduce vibrations, making machines run smoother. Materials like aluminum or steel also play a key role in absorbing shocks. Optimizing the size and shape of the pulley can further decrease vibrations. Smaller, well-shaped pulleys help keep operations steady and efficient. This careful design means less wear and tear on the metal lathe.

Why is pulley weight important for vibration reduction?

Pulley weight is crucial for reducing vibrations. A heavier pulley can stabilize the machine, making it easier to work without shaking.

Key factors in effective pulley design:

- Weight: A heavier pulley helps absorb vibration.

- Material: Strong materials minimize shock and improve stability.

- Shape: A well-designed shape lowers vibration levels.

- Size: Smaller pulleys can lead to steadier operation.

Vibration Damping Techniques

Use of vibration dampening materials. Installation of damping mounts and supports.When it comes to keeping machines calm, vibration dampening materials are the unsung heroes. These materials absorb those pesky buzzes and shakes. Think of them as a cozy blanket for your metal lathe! Installing damping mounts and supports can help silence the noise even more. It’s like giving your lathe a good hug. Proper placement can drastically reduce vibrations, leading to smoother operations. If your lathe could talk, it would definitely say, “Thank you!”

| Technique | Description |

|---|---|

| Vibration Dampening Materials | Materials that absorb vibrations, reducing noise and wear. |

| Damping Mounts | Supports that help stabilize the machine and lessen vibrations. |

Balancing the Lathe System

Importance of dynamic balancing. Methods for balancing lathe components.Dynamic balancing is key for smooth lathe operation. When lathe parts fit well, they spin correctly. This reduces wasted energy and noise. Several methods help with balancing:

- Weight Addition: Attach extra weights where needed.

- Adjusting Placement: Move parts to find a better balance.

- Precision Tools: Use tools like balancers to check spins.

When lathe systems are balanced, it boosts performance and extends equipment life. A well-balanced lathe is less likely to suffer from vibrations. This means better work and safer use.

Why is dynamic balancing important?

Dynamic balancing minimizes vibrations and improves cutting accuracy. It also helps the lathe last longer and reduces repairs.

Maintenance Practices to Minimize Vibration

Regular inspection and maintenance routines. Lubrication and its role in reducing friction and vibration.Keeping a metal lathe running smoothly is like keeping a cat happy: it takes effort! Start with regular inspections to catch problems early. Check belts and pulleys. A small issue can turn into a big mess, faster than you can say “lathe.” Don’t skimp on lubrication, either. It reduces friction and helps minimize vibration. Think of it as giving your machine a nice massage! Regular care is the secret to happy lathes and happy users!

| Maintenance Tip | Description |

|---|---|

| Regular Inspection | Look for wear and tear on belts and pulleys. |

| Lubrication | Apply grease to reduce friction and vibrations. |

Case Studies and Real-World Applications

Examples of successful vibration reduction in industrial settings. Lessons learned from practical implementations.Many industries have seen success in reducing lathe vibration. This makes machines run smoother and last longer. For example, a car parts factory improved its output by 30% after using new metal lathe pulleys. The smoother operation led to fewer defects in parts.

Here are some lessons learned:

- Regular maintenance stops vibrations before they start.

- Choosing the right pulleys can drastically cut noise and wear.

- Sharing knowledge with employees helps everyone spot issues quickly.

What industries benefit from vibration reduction?

Industries such as automotive, aerospace, and machining benefit greatly from vibration reduction techniques.

Conclusion

In summary, reducing lathe vibration is crucial for better metalworking. Using a pulley system can help minimize vibrations effectively. You can improve your projects by choosing the right materials and tools. Remember, vibration control leads to smoother cuts and better finishes. For more tips, consider reading articles on machining techniques or experimenting with different setups in your workshop!FAQs

What Are The Common Causes Of Vibration In Metal Lathe Pulley Systems, And How Can They Be Identified?Vibrations in metal lathe pulley systems can happen for several reasons. First, the pulleys might be unbalanced. You can spot this by listening for loud noises or feeling shaking. Second, the belts can be loose or worn out. Check if they look frayed or too loose. Finally, parts might be loose or damaged. You can fix this by tightening screws and checking for breaks or cracks.

How Do Different Materials Used For Lathe Pulleys Impact Vibrations And Overall Machine Performance?The material of lathe pulleys affects how much they vibrate. If we use heavy materials like steel, they usually vibrate less. Lighter materials, like plastic, can vibrate more, which can make the machine less steady. Less vibration means better performance for the lathe, helping it work smoothly. So, choosing the right material is really important for how well the machine runs.

What Techniques Or Technologies Are Available For Reducing Vibration In Lathe Pulley Systems?To reduce vibration in lathe pulley systems, you can use several techniques. First, balance the pulleys properly so they spin evenly. You can add rubber mounts to absorb shocks and keep things steady. Using flexible belts instead of stiff ones can also help. Lastly, regular maintenance helps find and fix problems before they cause more vibrations.

How Can The Alignment And Balance Of Lathe Pulleys Affect Vibration Levels During Machining Operations?When lathe pulleys are aligned and balanced well, they help machines run smoothly. If they are not, it creates extra shaking and noise. This shaking can cause mistakes in what we are making. To keep our work quality good, we need those pulleys to be in the right place and balanced. Less vibration means better results!

What Role Does Regular Maintenance Play In Minimizing Vibration In Metal Lathe Pulley Setups?Regular maintenance helps keep the metal lathe pulleys in good shape. By checking and tightening parts, we stop them from moving too much. When everything is tight and clean, there’s less shaking. This makes your work easier and safer. So, keeping the lathe clean and checked means less vibration!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Causes Of Vibration In Metal Lathe Pulley Systems, And How Can They Be Identified? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibrations in metal lathe pulley systems can happen for several reasons. First, the pulleys might be unbalanced. You can spot this by listening for loud noises or feeling shaking. Second, the belts can be loose or worn out. Check if they look frayed or too loose. Finally, parts might be loose or damaged. You can fix this by tightening screws and checking for breaks or cracks.”}},{“@type”: “Question”,”name”: “How Do Different Materials Used For Lathe Pulleys Impact Vibrations And Overall Machine Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of lathe pulleys affects how much they vibrate. If we use heavy materials like steel, they usually vibrate less. Lighter materials, like plastic, can vibrate more, which can make the machine less steady. Less vibration means better performance for the lathe, helping it work smoothly. So, choosing the right material is really important for how well the machine runs.”}},{“@type”: “Question”,”name”: “What Techniques Or Technologies Are Available For Reducing Vibration In Lathe Pulley Systems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in lathe pulley systems, you can use several techniques. First, balance the pulleys properly so they spin evenly. You can add rubber mounts to absorb shocks and keep things steady. Using flexible belts instead of stiff ones can also help. Lastly, regular maintenance helps find and fix problems before they cause more vibrations.”}},{“@type”: “Question”,”name”: “How Can The Alignment And Balance Of Lathe Pulleys Affect Vibration Levels During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When lathe pulleys are aligned and balanced well, they help machines run smoothly. If they are not, it creates extra shaking and noise. This shaking can cause mistakes in what we are making. To keep our work quality good, we need those pulleys to be in the right place and balanced. Less vibration means better results!”}},{“@type”: “Question”,”name”: “What Role Does Regular Maintenance Play In Minimizing Vibration In Metal Lathe Pulley Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance helps keep the metal lathe pulleys in good shape. By checking and tightening parts, we stop them from moving too much. When everything is tight and clean, there’s less shaking. This makes your work easier and safer. So, keeping the lathe clean and checked means less vibration!”}}]}