Imagine watching a beautiful piece of metal spin and transform under a lathe’s cutting edge. It’s fascinating, isn’t it? But have you ever noticed how vibration can ruin that perfect finish? If you’ve ever worked with a metal lathe, you know that setup is crucial. Proper lathe vibration reduction can make all the difference.

What if I told you that small adjustments could lead to smoother cuts and better results? It might sound simple, but the right setup can help reduce vibrations that affect your work. Consider how much smoother your projects could be with a few easy changes. This article will explore the best practices for achieving a great metal lathe setup.

Let’s dive deeper into the world of lathe vibration reduction. Together, we will learn how to create a workspace that brings out the best in your metal lathe. The right tips can turn your projects from ordinary to extraordinary. Are you ready to take your metalworking skills to the next level?

Lathe Vibration Reduction: Optimizing Metal Lathe Setup

Lathe Vibration Reduction Metal Lathe Setup

Setting up a metal lathe involves more than just placing parts together. Lathe vibration can impact the quality of your work. Reducing vibration leads to smoother cuts and better finishes. Have you ever noticed how a shaky machine can ruin a project? This setup helps stabilize your lathe. Using a solid base, proper alignment, and dampening materials can greatly enhance performance. With these tips, you’ll achieve precise and professional results!Understanding Lathe Vibration

Definition and causes of lathe vibration. Importance of reducing vibration for machining accuracy.Lathe vibration happens when the machine shakes while it cuts metal. This shaking can come from unbalanced parts or the wrong speed settings. Reducing vibration is very important. When there is less vibration, the parts fit better and look smoother. This makes your job easier and the products are more reliable. Did you know that even a tiny amount of vibration can change how well the machine works? Keeping vibrations low helps improve accuracy.

What causes lathe vibration?

Common causes of lathe vibration include:

- Unbalanced workpieces

- Poor machine setup

- Incorrect tool cutting angles

- Excessive tool wear

How does vibration affect machining accuracy?

Vibration can lead to defects in the finished product. It can create rough surfaces or uneven shapes, which is not what we want!

Key Factors Influencing Lathe Vibration

Machine design and construction quality. Workpiece material and geometry impacts.Several factors can lead to unwanted lathe vibrations, affecting your metalwork dreams. First, the machine design and construction quality play a huge role; a sturdy lathe is less likely to wiggle around like a worm after a rainstorm! Next, check the workpiece material and geometry. Softer materials might bounce, while complex shapes can cause uneven forces. Remember, a well-balanced setup is your best buddy in preventing those pesky vibrations!

| Factor | Impact on Vibration |

|---|---|

| Machine Design | Sturdy machines reduce vibrations |

| Construction Quality | Poor quality leads to more wobbles |

| Material Type | Soft materials may vibrate more |

| Workpiece Geometry | Complex shapes can cause issues |

Strategies for Lathe Vibration Reduction

Proper tool selection and positioning techniques. Balancing and securing workpieces effectively.Keeping vibrations low on a lathe makes your work smoother. First, choose the right tool and place it correctly. A well-placed tool can work wonders. It’s like finding your favorite snack in the fridge—much easier to enjoy! Next, make sure your workpieces are balanced and secured well. If they wobble, it’s like trying to ride a unicycle on a tightrope. Here’s a simple table to help you remember the basics:

| Strategy | Description |

|---|---|

| Tool Selection | Pick tools that suit your material. |

| Tool Positioning | Place tools at the right angle for cuts. |

| Workpiece Balancing | Center and secure pieces tightly. |

These strategies help reduce vibrations while you work, giving you better results and maybe even a happy dance when you’re done!

Importance of Lathe Setup and Maintenance

Regular inspection and alignment of lathe components. Lubrication practices and their role in vibration control.Proper setup and maintenance of a lathe are crucial for smooth operation. Regularly inspecting and aligning the lathe components helps keep everything in place. This reduces vibrations that can affect your work quality. Lubricating the machine parts is equally important. It lessens friction and contributes to better vibration control. Here are some key reasons:

- Regular inspections catch problems early.

- Alignment ensures parts move correctly.

- Lubrication prevents wear and tear.

- Less vibration leads to better results.

Why is lubrication important for lathe machines?

Lubrication is vital because it helps reduce friction between moving parts. This means less wear, better performance, and fewer vibrations. Regular lubrication keeps your lathe running smoothly.

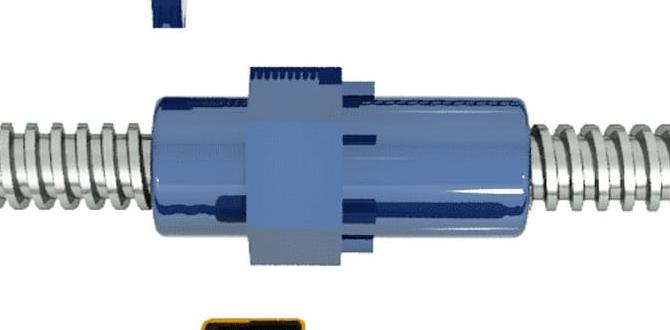

Advanced Techniques for Vibration Control

Use of damping materials and isolation mounts. Implementation of vibration analysis technology.To control vibrations in metal lathes, using damping materials and isolation mounts is key. Damping materials absorb shock and reduce noise. Isolation mounts keep the lathe stable, preventing movement. Vibration analysis technology helps identify problem areas. This means less wear and tear on the machine and better performance overall.

- Damping materials can include rubber or foam.

- Isolation mounts are designed to limit vibrations.

- Vibration analysis measures lathe performance.

What are the benefits of damping materials?

Damping materials reduce noise and enhance the lathe’s stability. This leads to a smoother operation and longer tool life, making tasks easier.

Why use vibration analysis technology?

It identifies issues early on, preventing costly repairs. Regular checks can save time and money, ensuring your lathe is working its best.

Real-World Applications and Case Studies

Examples of successful vibration reduction in various industries. Lessons learned from common setup failures and solutions.Many industries have successfully reduced lathe vibrations, leading to better product quality and fewer defects. For example, a car manufacturer saw a 25% drop in errors after improving their lathe setup. They realized that even small changes can make a big difference! Lessons from mishaps often show that ignoring vibrations can lead to costly mistakes. Solutions include using special mounts or adjusting speeds. Remember, silence isn’t golden—it’s a smoother finish!

| Industry | Vibration Reduction Examples | Lessons Learned |

|---|---|---|

| Manufacturing | 25% drop in errors | Check mounts regularly! |

| Aerospace | Improved part longevity | Speed adjustments matter! |

| Woodworking | No more splinters | Balance tools carefully! |

Conclusion

In summary, reducing lathe vibration improves your metalworking results. You can achieve better accuracy by stabilizing your setup and balancing your tools. Remember to check for tight connections and use quality materials. By taking these steps, you enhance your projects. For more tips, keep exploring resources on lathe setups. Happy machining, and keep learning!FAQs

What Are The Common Causes Of Vibration In Metal Lathe Setups, And How Can They Be Identified?Vibration in metal lathes can happen for a few reasons. First, the tools might be set up wrong or are worn out. Second, the metal piece could be too heavy or not balanced properly. Third, loose parts or screws can make things shake. We can find these problems by checking if everything is tight and balanced. Listening for strange noises helps, too!

How Can The Alignment Of The Lathe Be Optimized To Reduce Vibration During Operation?To reduce vibration in a lathe, you need to align it properly. First, check that the lathe is level on the ground. Next, make sure the parts are tight and not loose. You can also balance the workpiece before spinning it. By doing these things, you help the lathe run smoothly!

What Role Do Tooling And Workpiece Selection Play In Minimizing Vibration On A Metal Lathe?Tooling and workpiece selection are important to keep a metal lathe running smoothly. When you choose the right tools, they fit better and cut more evenly. This helps reduce vibrations. Picking the right workpiece, or what you are working on, also helps. A balanced workpiece makes less noise and vibrates less, making your work easier!

What Are Some Effective Damping Techniques Or Materials That Can Be Used To Reduce Lathe Vibration?To reduce lathe vibration, we can use several effective techniques and materials. Adding soft rubber pads under the lathe helps absorb vibrations. Using heavy weights can also lower the shaking. You can wrap the lathe in special damping cloths that reduce noise and movement. Lastly, keeping the lathe well-balanced helps it run smoother with less vibration.

How Does Spindle Speed Affect Vibration Levels In A Metal Lathe, And What Adjustments Can Be Made To Mitigate This Issue?Spindle speed is how fast the lathe spins the metal. If it’s too fast, the machine can shake and vibrate. We can lower the speed to make it smoother. We can also balance the lathe parts better or check for loose screws. Doing these things helps us work safely and make better pieces.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Causes Of Vibration In Metal Lathe Setups, And How Can They Be Identified? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibration in metal lathes can happen for a few reasons. First, the tools might be set up wrong or are worn out. Second, the metal piece could be too heavy or not balanced properly. Third, loose parts or screws can make things shake. We can find these problems by checking if everything is tight and balanced. Listening for strange noises helps, too!”}},{“@type”: “Question”,”name”: “How Can The Alignment Of The Lathe Be Optimized To Reduce Vibration During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in a lathe, you need to align it properly. First, check that the lathe is level on the ground. Next, make sure the parts are tight and not loose. You can also balance the workpiece before spinning it. By doing these things, you help the lathe run smoothly!”}},{“@type”: “Question”,”name”: “What Role Do Tooling And Workpiece Selection Play In Minimizing Vibration On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tooling and workpiece selection are important to keep a metal lathe running smoothly. When you choose the right tools, they fit better and cut more evenly. This helps reduce vibrations. Picking the right workpiece, or what you are working on, also helps. A balanced workpiece makes less noise and vibrates less, making your work easier!”}},{“@type”: “Question”,”name”: “What Are Some Effective Damping Techniques Or Materials That Can Be Used To Reduce Lathe Vibration? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce lathe vibration, we can use several effective techniques and materials. Adding soft rubber pads under the lathe helps absorb vibrations. Using heavy weights can also lower the shaking. You can wrap the lathe in special damping cloths that reduce noise and movement. Lastly, keeping the lathe well-balanced helps it run smoother with less vibration.”}},{“@type”: “Question”,”name”: “How Does Spindle Speed Affect Vibration Levels In A Metal Lathe, And What Adjustments Can Be Made To Mitigate This Issue? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe spins the metal. If it’s too fast, the machine can shake and vibrate. We can lower the speed to make it smoother. We can also balance the lathe parts better or check for loose screws. Doing these things helps us work safely and make better pieces.”}}]}