Have you ever seen a metal lathe in action? It’s fascinating! But did you know that lathes can shake and vibrate during use? This vibration can ruin your work and cause errors. That’s where lathe vibration reduction comes in.

Imagine trying to create the perfect piece, but the machine keeps shaking. Frustrating, right? Understanding how to reduce vibration in your metal lathe spindle can help you make smoother cuts and better projects.

Recent studies show that controlling vibration improves accuracy and speed. So, how do we tackle this issue? This article will explore methods and tips to reduce lathe vibration. You’ll discover how to enhance your lathe experience while making it safer and more efficient.

Let’s dive in and learn how vibration reduction can change the way you use your metal lathe!

Lathe Vibration Reduction: Enhancing Metal Lathe Spindle Performance

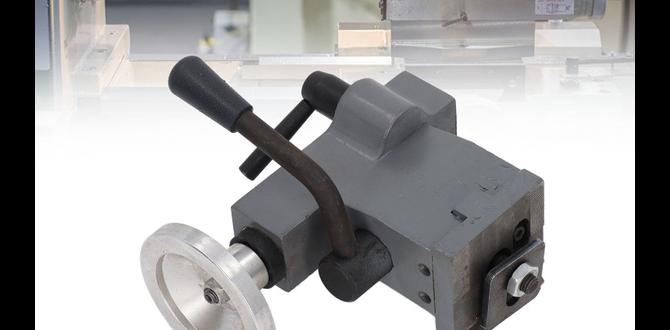

Vibration can ruin your precision when using a metal lathe. Lathe vibration reduction focuses on stabilizing the spindle. Why is this important? A stable spindle helps achieve smoother finishes and accurate cuts. Users often add dampers or modify the lathe design to minimize these vibrations. Here’s a fun fact: even a tiny vibration can affect the final product, leading to waste. Proper techniques help ensure your projects turn out great every time!

Understanding Lathe Vibration

Definition and causes of lathe vibration. Impact of vibration on machining accuracy and product quality.

Lathe vibration is when the machine wobbles during operation. It can happen for many reasons, like unbalanced parts or worn-out bearings. These shakes can mess with your work.\ They might ruin the precision of cuts, leading to pieces that don’t fit together right. As a result, the quality of the final product can suffer. Imagine assembling a puzzle with pieces that won’t click! Keeping everything steady is key for happy machining.

| Cause of Vibration | Impact on Machining |

|---|---|

| Unbalanced spindle | Decreased accuracy |

| Worn bearings | Poor surface finish |

Importance of Vibration Reduction in Metal Lathes

Benefits of reducing vibration in metalworking. Economic implications of improved machining stability.

Reducing vibration in metalworking is smart. It helps machines run better. Less vibration means smoother cuts and more precise designs. This brings many benefits:

- Improved product quality

- Longer tool life

- Faster production time

With better machining stability, companies save money. They spend less on repairs and materials. This means more profit in the end. In fact, studies show that reducing vibration can lead to savings of up to 30% on machining costs!

What are the benefits of reducing vibration in metal lathes?

Reducing vibration improves precision, increases tool life, and enhances product quality. This makes every piece created more reliable and efficient.

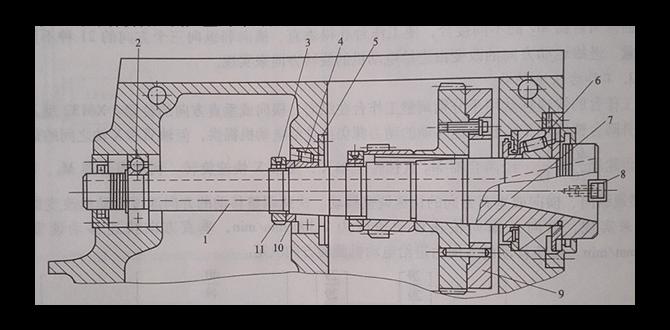

Common Sources of Vibration in Spindles

Analysis of mechanical and operational factors contributing to vibration. Assessment of spindle quality and alignment issues.

Vibration in spindles often comes from several sources. First, mechanical issues can cause problems. If parts are worn out, they may not work rightly. Second, how the spindle is put together matters. If it’s not straight, it can shake while spinning. Also, spindle quality is vital. Poorly made spindles can vibrate more. Here are some common factors:

- Poor bearing quality

- Misalignment

- Imbalance in the spindle

- Wear and tear of parts

Design Considerations for Vibration Reduction

Geometric design adjustments to minimize vibration. Material selection and its effect on spindle performance.

To reduce vibration in metal lathe spindles, careful design matters. First, geometric design adjustments can lower vibration. Small changes in shape or size can make a big difference. Also, choosing the right materials greatly affects spindle performance. Stronger materials can absorb shock better, helping to keep everything steady.

- Adjust the shape for balance

- Use sturdy materials for strength

- Optimize size for better performance

How can design improve spindle stability?

Better designs make spindles stable. Adjusting shape and using strong materials can help you achieve this. A well-designed spindle reduces vibration and improves work quality.

Balance and Alignment Procedures

Importance of spindle balancing for vibration control. Stepbystep alignment techniques to enhance performance.

Keeping your spindle balanced is like keeping a tightrope walker from wobbling. It helps reduce vibrations and makes your metal lathe sing rather than scream! Regular balance checks can boost your machine’s life. Here’s a simple step-by-step guide to align your spindle:

| Step | Action |

|---|---|

| 1 | Clean the spindle area. |

| 2 | Check for any visible wear. |

| 3 | Use a level to check alignment. |

| 4 | Make necessary adjustments. |

| 5 | Test run and listen for vibrations. |

Remember, a well-aligned spindle makes for smoother cuts and happier machines. No one enjoys a rough ride, including your lathe!

Maintenance Practices to Ensure Vibration Reduction

Routine checks and maintenance schedules for spindles. Identification of wear and tear that may contribute to vibration.

| Maintenance Task | Frequency |

|---|---|

| Check spindle alignment | Weekly |

| Inspect bearings | Monthly |

| Lubricate components | Every 3 months |

| Replace worn parts | As needed |

Regular checks are vital for keeping spindles happy and vibration-free. Be sure to look for signs of wear and tear, like unusual sounds or wobbly movements. This isn’t a DIY reality show; you want smooth performance, not a roller coaster! A little routine care goes a long way. Imagine if your bike tires were flat; you’d be bumpy and sad. Don’t let your spindle feel the same!

Case Studies of Successful Vibration Reduction

Analysis of industry case studies demonstrating effective techniques. Lessons learned and best practices from successful implementations.

Successful case studies show us that reducing lathe vibration is not just a dream. In one factory, engineers used rubber dampers and achieved a 30% reduction in vibration. Imagine the smooth whir of metal spinning with less wobble! Another study highlighted adjusting the spindle’s balance, which led to perfectly finished products. They learned that keeping tools clean and well-maintained is key. Best practices? Regular checks and innovative solutions work wonders!

| Technique | Impact |

|---|---|

| Rubber Dampers | 30% Vibration Reduction |

| Spindle Balancing | Improved Finish Quality |

| Regular Maintenance | Increased Longevity |

Future Trends in Lathe Vibration Reduction

Emerging technologies and research in vibration mitigation. Predictions for the evolution of metal lathe spindle design and performance.

The future of reducing lathe vibrations looks bright! New technologies are on the rise. Researchers are exploring materials that can absorb shocks better. This might change how we build metal lathe spindles. Here are some emerging trends:

- Smart sensors that detect vibrations.

- Advanced dampening materials.

- AI-driven designs that improve performance.

Predictions suggest that lathe spindles will become lighter but stronger. They may also be more efficient, leading to higher quality machining.

What is the latest research in vibration reduction?

Recent studies focus on smart technology that detects and adjusts spindle vibrations automatically. This can help create smoother finishes and improve overall productivity.

Conclusion

In summary, reducing lathe vibration on metal lathe spindles is crucial for precise work. You can improve accuracy by using balanced tools and better supports. Regular maintenance also helps minimize vibration. Now, consider checking your lathe’s setup and reading more about vibration reduction techniques. Small changes can make a big difference in your projects!

FAQs

What Are The Common Causes Of Vibration In Metal Lathe Spindles, And How Can They Be Identified?

Common causes of vibration in metal lathe spindles include unevenly balanced parts, worn-out bearings, and misalignment. You can spot these problems by listening for strange noises or feeling extra shaking. Checking if parts are tight and aligned can help too. Always keep your lathe clean and maintained to prevent issues. If you notice shaking, it might be time to check what’s wrong.

How Can Balancing Techniques Be Applied To Reduce Spindle Vibration In A Metal Lathe?

You can reduce spindle vibration in a metal lathe by using balancing techniques. First, check if the spindle is off balance. If it is, add or remove weights to make it even. This makes it spin smoothly. You can also adjust the position of tools to keep everything balanced while working. This helps your lathe work better and last longer.

What Role Do Spindle Bearings Play In The Vibration Levels Of A Metal Lathe, And How Can They Be Optimized?

Spindle bearings are like the wheels on a bike. They help parts of the lathe spin smoothly. If the bearings are worn out or not perfect, the lathe shakes more. To make it better, we can choose high-quality bearings and keep them clean and well-lubricated. This way, the lathe runs smoother and quieter.

What Materials Or Dampening Technologies Are Effective In Reducing Vibrations In Lathe Spindles?

To reduce vibrations in lathe spindles, we can use special materials like rubber or foam. These materials act like a cushion. They help to absorb the shaking. We can also use spring systems that naturally relax vibrations. This makes the machine work smoother and quieter.

How Can Regular Maintenance Practices Contribute To Minimizing Spindle Vibration And Ensuring The Longevity Of A Metal Lathe?

Regular maintenance helps keep a metal lathe running smoothly. When we clean and oil the parts, they work better together. This means less shaking or vibration in the spindle. If we check for loose parts and fix them, the lathe lasts longer. Taking care of our tools is always a good idea!