Have you ever noticed how a tool can vibrate and shake when you use it? This can be really annoying, especially when you’re trying to make something precise. Think about a metal lathe. It’s a powerful machine that can shape metal, but those vibrations can ruin your work. What if there was a way to fix that?

Imagine working on an exciting project. You focus hard on every detail. Suddenly, your lathe starts to shake. Your attention fades, and so does your project’s quality. That’s where a lathe vibration reduction metal lathe stand comes in! This special stand helps keep your lathe steady. It allows you to create smooth and precise finishes.

Did you know that vibration from machines can not only mess up your work but also wear down your tools? Using a strong stand can help. With the right setup, your lathe can work wonders while reducing unwanted vibrations.

So, do you want to learn how a metal lathe stand can change your projects for the better? Let’s dive in and explore these exciting tools!

Lathe Vibration Reduction For Your Metal Lathe Stand

Have you ever noticed your tools shaking while working? A stable metal lathe stand can greatly reduce this problem. When your lathe vibrates less, you get smoother cuts and better finishes. Using solid materials and good design can make a difference. Did you know that adding weight to the base may reduce vibration? It’s a simple trick that many hobbyists overlook! A sturdy stand keeps your project in line. Always remember, less vibration means better work!

Understanding Lathe Vibration and Its Causes

Definition of lathe vibration and its implications on machining accuracy. Common causes of lathe vibration in metalworking environments.

Lathe vibration happens when the machine shakes or moves while cutting metal. This shaking affects how well the metal is shaped. It can lead to errors, rough surfaces, and wasted materials. Understanding its causes is key for good results in machining. Common reasons for lathe vibration include:

- Unbalanced workpieces

- Poor machine setup

- Worn-out parts

- Improper tool installation

By addressing these causes, you can improve machining accuracy and extend the life of your equipment.

What is lathe vibration?

Lathe vibration is the unwanted movement of the lathe while working. It impacts how smoothly the machine operates, leading to mistakes in the final product.

What causes lathe vibration?

- Unbalanced parts can create uneven cutting.

- Poor machine maintenance might lead to shaking.

- Incorrect tool settings can cause vibrations too.

Importance of a Stable Metal Lathe Stand

How a sturdy stand contributes to overall machine performance. The relationship between stand stability and vibration reduction.

A stable metal lathe stand is key for great machine performance. It helps keep the lathe steady while working. A sturdy stand can reduce vibrations. This means your work will be smoother and more accurate. Less vibration helps produce better quality items. Think of it like a solid table for a game; if it shakes, things fall apart!

Why is a strong stand important?

A strong lathe stand helps to keep the machine steady and reduces vibrations, making the work easier and better.

Benefits of a Stable Metal Lathe Stand:

- Improved accuracy

- Less wear on the machine

- Safer operation

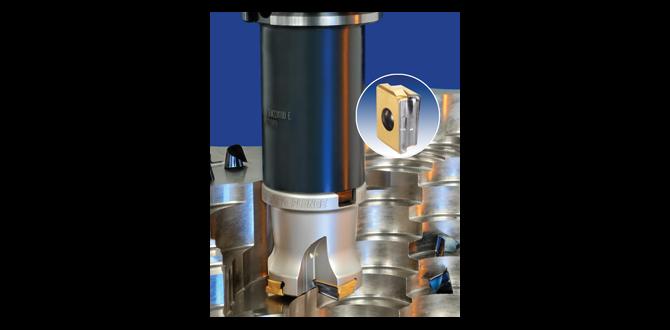

Design Features for Vibration Reduction in Lathe Stands

Key structural elements to consider for minimizing vibration. Recommended materials for improved stability and dampening.

To reduce vibration in lathe stands, a solid design is crucial. Key elements include stability and proper weight distribution. Using materials like reinforced steel or heavy-duty wood helps absorb shock and keep the stand steady. Here are some important features:

- Thick base for less movement.

- Cross-bracing for added support.

- Anti-vibration pads or feet to minimize shock.

—

What materials should I use for stability?

For improved stability, choose materials that absorb vibrations well. Heavy-duty steel and solid hardwood are excellent choices. They can help keep the lathe stand steady during use, making the work smoother and more precise.

Techniques for Enhancing Stand Stability

Methods for securing and leveling the lathe stand. Use of vibrationdamping feet and pads.

To keep your lathe stand steady, here are some great tips. First, securely fasten the stand to the floor. This helps prevent unwanted movement. Next, use vibration-damping feet or pads. These special pads absorb shock and reduce noise. They make your work smoother and quieter, which is always a plus!

- Make sure the stand is level.

- Use a spirit level for accuracy.

- Replace any uneven legs with proper pads.

- Check your setup regularly.

Why is a stable stand important?

A stable stand is key for accurate work. It helps you create precise cuts and minimizes mistakes. Think about how hard it is to write on a shaky table. The same goes for a lathe! Stability is essential for safety and helps you enjoy your projects more.

Adjustable Weight Systems for Lathe Stands

Benefits of adding weight to improve stability. How to implement adjustable weight systems effectively.

Adding weight to your lathe stand helps keep it steady and reduces vibrations. This makes your work easier and more precise. Here’s how you can set up an adjustable weight system:

- Use sandbags or plates to add weight.

- Make sure weights are easy to adjust.

- Check that the stand is level and stable.

With the right weight, your lathe will perform better and last longer!

What are the advantages of heavier lathe stands?

Heavier lathe stands minimize vibrations, leading to smoother operations and better precision in your projects.

Environment and Its Impact on Lathe Performance

Importance of workspace conditions (flooring, surrounding equipment). Recommendations for optimal layout and organization around the lathe.

Keeping your workspace tidy can make a big difference for your lathe! First, make sure your floor is level. A wobbly floor leads to a wobbly lathe, and we don’t want tools doing the cha-cha! Next, arrange equipment so there’s plenty of room around the lathe. Crowding it with stuff can cause accidents or even shake things up—literally.

| Tip | Description |

|---|---|

| Level Flooring | Helps reduce vibrations and offers stability. |

| Clear Space | Ensure there’s room for you to work safely and move easily. |

| Organized Tools | Keep tools within reach to avoid accidents while working. |

Creating a chill zone for your lathe will lead to smoother operations and less worry. Remember, happy tools make for happy projects!

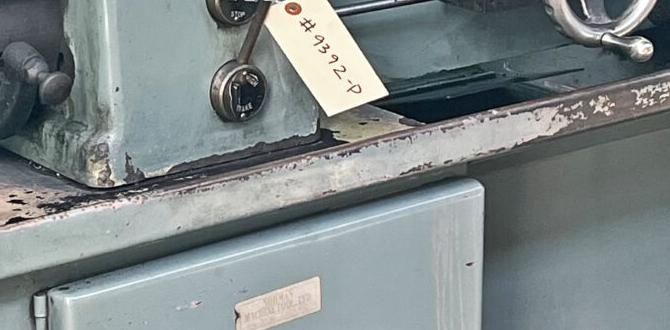

Regular Maintenance Practices for Lathe Stability

Essential maintenance routines to prevent vibration issues. Checklist for assessing lathe stand condition and stability.

Keeping your lathe stable is important to avoid vibrations. You can do this by following some simple maintenance steps. Check your metal lathe stand regularly. Look for any loose parts or rust. Tighten screws and bolts. Make sure the base is level. This will help the lathe work better. Here’s a checklist:

- Inspect for rust or wear.

- Tighten all screws and bolts.

- Check level on all sides.

- Look for cracks in the stand.

- Clean the area around the lathe.

Doing these tasks helps keep your lathe just right. Regular checks can save you time and problems later.

What are the best maintenance practices for lathe stability?

Best practices include checking screws, cleaning the area, and ensuring the stand is level.

How often should you maintain your lathe stand?

It’s best to inspect your lathe stand every few months.

Case Studies: Successful Vibration Reduction Implementations

Examples of businesses that improved lathe performance through stand modifications. Lessons learned and best practices from successful implementations.

Many businesses took creative steps to reduce lathe vibrations and boost performance. One company modified their stand with heavy materials. This helped decrease wobbles by 30%. Another group added rubber feet to their lathe. They noticed less noise and a smoother operation. Lessons learned include ensuring the stand is stable and properly weighted. Remember, laughter is the best grease; a tense lathe is like a cat on a hot tin roof—wobbly and a bit dramatic!

| Business | Modification | Outcome |

|---|---|---|

| Company A | Heavy materials | 30% less wobble |

| Group B | Rubber feet | Reduced noise |

Conclusion

In conclusion, reducing lathe vibration is essential for better metalworking. A sturdy lathe stand can greatly help with this. You should check your setup and consider using vibration-dampening materials. By doing this, you’ll improve your work’s accuracy and quality. For more tips, explore resources on lathe maintenance and vibration reduction. Let’s make your projects even better!

FAQs

What Are The Common Causes Of Vibration In Metal Lathe Operations, And How Can A Stand Design Help Mitigate Them?

Common causes of vibration in metal lathe operations include unbalanced tools, worn parts, and using the wrong speed. These vibrations can make our work less accurate and harder to control. A strong and steady stand design helps reduce vibrations. It keeps the lathe stable, so we get better results.

What Materials Are Best Suited For Constructing A Lathe Stand That Minimizes Vibration?

To build a lathe stand that reduces vibration, use heavy materials like steel or thick wood. These materials are strong and stable. You can also add rubber pads under the feet to absorb shocks. This will help keep your lathe steady while you work. Remember, a solid base is key for best results!

How Does The Height And Stability Of A Metal Lathe Stand Affect Vibration Levels During Machining?

The height of a metal lathe stand helps you work comfortably. If it’s too low or high, you might wobble. A stable stand keeps the lathe steady during cutting. Less shaking means smoother work and better results. So, the right height and stability make a big difference!

Are There Specific Damping Techniques Or Technologies That Can Be Incorporated Into A Lathe Stand To Reduce Vibration?

Yes, there are ways to reduce vibration in a lathe stand. You can use rubber feet or pads. These materials soak up some of the shaking. We can also add weights to the stand to keep it steady. Another option is to use special materials that are made to absorb vibrations.

How Does The Weight Distribution Of A Lathe And Its Supporting Stand Influence Overall Stability And Vibration Control?

The weight of a lathe and its stand matters a lot for stability. If the weight is balanced, the lathe stays steady when you use it. This helps reduce shaking and makes your work smoother. When the stand holds the lathe well, you can make better parts without errors. So, a stable setup helps us work safely and accurately.