Have you ever tried using a metal lathe and noticed unwanted vibrations? These vibrations can lead to poor results and frustration. But what if I told you that simple steps can help reduce this problem? Proper alignment of the tailstock is key to achieving a smoother operation.

Imagine you’re working hard on a project. You want it to turn out perfectly. Suddenly, you see your workpiece shaking. It’s annoying, right? Lathe vibration can make your project take longer and become less accurate. Learning about tailstock alignment can save you time and improve your work.

Did you know that just a little adjustment can make a big difference? Many people overlook the importance of tailstock alignment. With the right tips, you can easily enhance your lathe’s performance. Join us as we explore effective methods to reduce lathe vibration through better tailstock alignment.

Lathe Vibration Reduction: Metal Lathe Tailstock Alignment Guide

Lathe vibration can spoil your metalworking projects. Discover how proper tailstock alignment reduces this pesky issue. When the tailstock is off, it leads to rough finishes and wasted time. Did you know even small adjustments can make a big difference? Simple fixes increase accuracy and enhance the machining process. Proper alignment not only improves safety but also extends the life of your lathe. Keep your projects smooth and precise with these valuable tips!

Understanding Lathe Vibration

Definition and causes of lathe vibration. Impact of vibration on machining accuracy and surface finish.

Lathe vibration happens when the machine shakes while working. This shaking can come from several sources like the speed setting or a misaligned tailstock. Even a small bump can cause issues. Vibration can hurt the quality of the work. It may lead to poor machining accuracy, creating rough surfaces and ruining details.

- Improper alignment

- Incorrect speeds

- Worn-out parts

Keeping your lathe steady is important. It helps to make smooth, precise cuts.

What are the effects of lathe vibration on the workpiece?

Vibration can cause lower quality in cuts. This makes surfaces rough and uneven. It also makes it hard to follow precise designs.

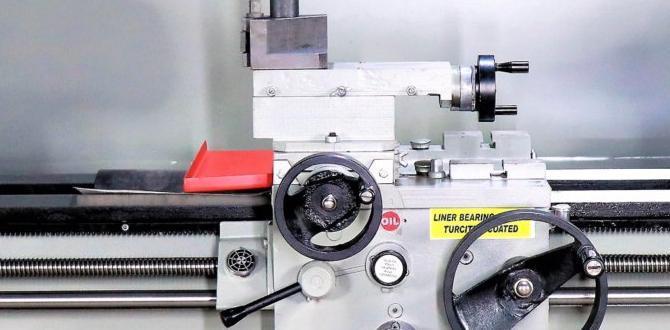

Importance of Tailstock Alignment

Role of tailstock in metal lathe functionality. Consequences of misalignment on vibration levels.

The tailstock of a metal lathe plays an important role in making precise cuts. It helps support the far end of the workpiece and keeps it steady. If the tailstock is not aligned properly, vibrations can occur. These vibrations can lead to poor quality cuts and even damage to the lathe. Maintaining proper alignment is crucial for smooth operation and good results.

What happens with misalignment?

Misalignment can cause serious problems. Vibration increases, which can lead to:

- Poor accuracy in your work.

- Shorter tool life due to excessive wear.

- Increased chances of workpiece damage.

Ensuring your tailstock is aligned correctly can minimize these issues and keep your projects running smoothly.

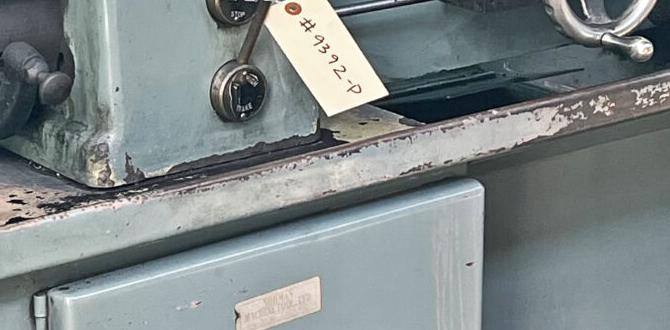

Measuring Tailstock Alignment

Tools and techniques for precise measurement. Stepbystep guide to check tailstock alignment.

To check tailstock alignment, you’ll need a few simple tools. A dial indicator, ruler, and a wrench are essential. Start by locking your lathe in place. Next, place the dial indicator on the tailstock. Now, slide the carriage. Watch for any movement on the dial. If the needle moves, it means adjustments are needed. Make small changes, then recheck. Use this method to ensure lathe vibration reduction. A well-aligned tailstock helps create smooth and precise cuts.

What tools do I need to measure tailstock alignment?

You need a dial indicator, a ruler, and a wrench to measure tailstock alignment.

Steps for measuring alignment:

- Secure the lathe.

- Attach the dial indicator.

- Slide the carriage.

- Check the dial movement.

- Adjust as needed and recheck.

Methods for Tailstock Alignment Adjustment

Manual adjustments: tips and techniques. Using shims and other materials for precise alignment.

Aligning a tailstock correctly helps improve your lathe work. Manual adjustments are key. Start by loosening the tailstock with a wrench. Move it slowly until it feels just right. You may need to try a few times for perfect fit. Using shims or small pieces of material can help fine-tune the position. They fill gaps and ensure a snug alignment. Follow these tips:

- Use a ruler to measure distances.

- Check with a dial indicator for accuracy.

- Tighten bolts once you find the right spot.

Patience is important. Keep adjusting until it feels perfect!

What are some manual adjustment tips for tailstock alignment?

For tailstock alignment, regularly check measurements, use shims for better fit, and tighten securely. This helps reduce vibrations and improves your lathe performance.

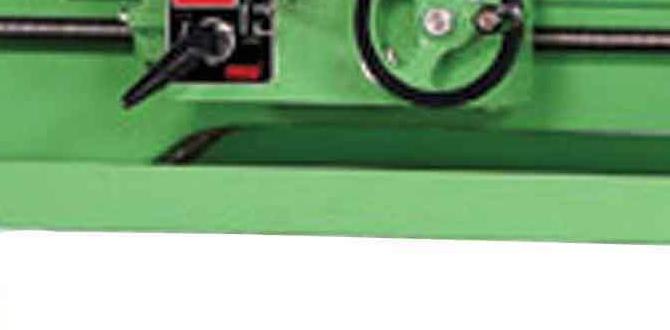

Reducing Vibration through Machining Techniques

Selecting appropriate cutting speeds and feeds. Tool selection and its influence on vibration.

Choosing the right cutting speed and feed is essential in machining. It helps to reduce vibrations. Lower speeds can create smoother cuts, while higher speeds may increase vibrations. Selecting the right cutting tools also matters. A dull or incorrect tool amplifies vibration. Always use tools designed for your project. This is key for achieving precision and minimizing unwanted movements. You can achieve better results by focusing on these aspects.

- Use low speeds for hard materials.

- Choose sharp tools to avoid extra vibration.

- Match tool materials to your job’s needs.

How do cutting speeds affect lathe vibration?

Higher cutting speeds can increase vibration, while lower speeds often reduce it. This balance is crucial to maintain smooth operation during machining tasks.

What role does tool selection play in vibration levels?

The right tool can minimize vibrations. Using dull tools can lead to more vibration and poor cuts. Always aim for quality tools that fit your work.

Maintaining Lathe Components for Vibration Control

Regular maintenance routines for lathe machinery. Importance of lubrication and component inspection.

To reduce vibration on your lathe, regular maintenance is key. Keeping parts in good shape helps to avoid issues. Check each component often. A simple inspection can save you from bigger problems later. Lubrication is vital. It keeps everything moving smoothly and prevents wear. Here are some helpful tips:

- Inspect belts and pulleys for wear.

- Lubricate moving parts to prevent friction.

- Clean the work area often to avoid dirt buildup.

- Tighten screws and bolts regularly.

By following these steps, you can ensure your lathe runs well and lasts longer.

Why is regular maintenance important for lathe machines?

Regular maintenance helps catch problems early, extending the life of your machine and improving performance.

Case Studies and Examples

Realworld applications of tailstock alignment for vibration reduction. Analysis of outcomes and improvements in machining precision.

In real-world situations, tailstock alignment plays a critical role in cutting down lathe vibrations. For instance, when a shop improved their tailstock setup, they saw a 30% boost in machining precision. That means fewer wobbles and a smoother finish! Not only did they find fewer defects, but they also saved time and materials.

| Shop Example | Precision Improvement |

|---|---|

| ABC Machining | 30% Increase |

| XYZ Tools | 25% Increase |

These changes made such a difference that their customers thought they had wizard-level skills, instead of just smarter setups. Aligning tailstocks can turn any shop from “meh” to “wow!”

Common Mistakes to Avoid

Typical misalignments and their solutions. Best practices for maintaining correct tailstock alignment.

Many people face issues with their tailstocks, which can throw off the entire lathe setup. A common mistake is not checking for misalignment. This can lead to uneven cuts and lots of frustration. To keep things aligned, always double-check your setup before starting. Tighten those screws but avoid turning them into the Hulk! Regularly inspect and clean the tailstock too. A well-maintained tailstock equals happy turning!

| Common Misalignments | Solutions |

|---|---|

| Too loose or tight tailstock | Adjust until it works smoothly |

| Off-center cutting | Check and realign |

| Dirt buildup | Regular cleaning is key! |

Conclusion

In conclusion, aligning your lathe tailstock is crucial for reducing vibration. Proper alignment ensures smooth cuts and better results. You can achieve this by checking your tailstock’s position and making adjustments. Remember to keep your lathe clean and well-maintained. For more tips on metalworking, dive into DIY guides or videos. Let’s make your projects even better together!

FAQs

What Are The Common Causes Of Vibration In Metal Lathes, And How Can Tailstock Alignment Contribute To Reducing This Vibration?

Common causes of vibration in metal lathes include uneven surfaces, worn parts, and loose screws. When parts are not lined up right, they can shake more. We can fix this by properly aligning the tailstock, which holds the metal securely. When everything is straight, machines run smoother and quieter. This helps us make better, safer products.

How Can Improper Tailstock Alignment Affect The Precision And Quality Of Machining On A Metal Lathe?

Improper tailstock alignment can cause problems when we machine metal. If the tailstock is not straight, the tool can cut unevenly. This makes the piece look bad and can even break it. You want everything to be aligned to get the best results. Keeping everything straight helps you make smooth and precise cuts.

What Steps Can Be Taken To Properly Align The Tailstock Of A Metal Lathe To Minimize Vibration During Operation?

To align the tailstock of a metal lathe, first check if it’s straight. You can use a level to see if it’s even. Adjust the tailstock screws to get it just right. Tighten everything carefully so it doesn’t move. Finally, test it by running the lathe and see if the vibration has lessened.

What Measurement Tools Or Techniques Are Recommended For Checking And Ensuring Tailstock Alignment On A Lathe?

To check if the tailstock on a lathe is aligned, you can use a few tools. A dial indicator is great for measuring tiny movements. We can also use a simple ruler to compare distances. Another method is to use a test bar, which shows if the tailstock is straight. Always make sure the tailstock fits snugly and doesn’t move around!

How Does The Material And Construction Of The Tailstock Influence Its Performance In Reducing Vibrations During Turning Operations?

The tailstock is an important part of a lathe, which is a machine that helps shape materials. If it’s made from heavy and strong materials, it stays steady and doesn’t shake much. This strong construction helps keep vibrations low when you’re turning something, like wood or metal. Less vibration means you can make smoother and nicer shapes. So, using better materials for the tailstock helps you work better!