Have you ever watched a lathe spinning, creating perfect shapes? It’s fascinating! But did you know that lathe vibration can mess up your beautiful designs? If you’re into metal lathe taper turning, you might face this issue more often than you think.

Vibration happens when the machine shakes while it works. This can ruin the quality of your work and drive you crazy! Imagine putting all that effort into a project, only to have it go wrong because of annoying vibrations.

Here’s a fun fact: many professionals say that reducing lathe vibration can help make smoother and more accurate cuts. So, how do you tackle this problem? Let’s explore some tips that can help you achieve better results while taper turning on a metal lathe. Your next project could be the best one yet!

Lathe Vibration Reduction For Metal Lathe Taper Turning

Lathe Vibration Reduction in Metal Lathe Taper Turning

Lathe vibration can be a major problem when taper turning on metal lathes. Excessive vibration leads to poor finishes and inaccurate cuts, costing time and materials. To tackle this, operators can use strategies like adjusting the speed and checking tool balance. Did you know that making small changes can significantly improve results? Reducing vibration helps achieve cleaner cuts, better surface quality, and longer tool life. Embracing these tips can elevate your machining skills effectively.Understanding Lathe Vibration

Definition of lathe vibration and its impact on machining quality. Common causes of vibration in metal lathe operations.Lathe vibration is like a funky dance your machine does when it shouldn’t. It can shake, rattle, and roll, impacting the quality of your work. Picture trying to draw a straight line while hopping on one foot! Common causes of this pesky vibration include poor tool setup, uneven workpieces, and even worn bearings. These issues can make your metal lathe operations feel like a wild ride instead of a smooth journey.

| Cause of Vibration | Description |

|---|---|

| Poor Tool Setup | Using the wrong tool can cause wobbling. |

| Uneven Workpieces | Items that aren’t balanced can throw everything off. |

| Worn Bearings | Old bearings might need a nap. Replace them! |

In short, understanding what makes your lathe vibrate can turn a shaky situation into a smooth operation.

Importance of Vibration Reduction

Effects of vibration on tool performance and surface finish. The relationship between vibration reduction and precision machining.Vibration can hurt tool performance. It makes cuts rough and uneven. This can lead to poor surface finish, making parts look bad. Precision machining needs stability. Reducing vibrations keeps tools steady. In turn, this helps create smoother surfaces and better shapes. Think of it this way: a calm hand makes a better drawing. By cutting down vibrations, machines work more efficiently and last longer.

Why is vibration reduction important?

Vibration reduction improves the quality of machine work. It helps tools produce cleaner, smoother, and more precise cuts. Better vibration control means longer tool life and higher accuracy.

Identifying Vibration Sources in Taper Turning

Analysis of machine construction and setup factors. Impact of tool selection and cutting parameters on vibration.Vibrations in taper turning can come from different sources. First, look at how the machine is built and set up. Poor alignment can lead to extra shakes. Next, think about the tools you use. The wrong tool can create more vibration. Also, cutting speeds and depths are important. Choose the right settings for smooth cutting.

- Check machine alignment.

- Use proper tools.

- Adjust cutting speed and depth.

What are common causes of vibration in metal lathes?

The main causes of vibration include machine setup issues, the wrong tool selection, and improper cutting parameters. These factors can lead to poor quality and unsafe operations.

Mechanical Solutions for Vibration Reduction

Use of vibration dampers and isolators. Upgrading machine components for enhanced stability.Vibrations can cause chaos in metal lathes. Luckily, there are clever tricks to tame them! Using vibration dampers and isolators can make a big difference. These tools help absorb shakes, keeping projects steady. Upgrading parts like bearings or frames enhances stability further. Think of it like putting a cozy blanket on your machine—it just feels better! Want your taper turning to be smooth? These upgrades could be the magic you need!

| Solution Type | Description |

|---|---|

| Vibration Dampers | Absorb vibrations to reduce impact on precision. |

| Isolators | Separate the machine from vibrations in the floor. |

| Component Upgrades | New parts boost strength and stability. |

By using these tools, you can create a smoother and more accurate lathe experience. Your projects will thank you!

Cutting Technique Adjustments

Best practices for tool geometry and material selection. Optimizing feed rates and cutting speeds to minimize vibration.Making the right cutting adjustments is crucial in reducing lathe vibration. Start by choosing the right tool shape and material; softer and harder materials can create chaos if mixed up. Next, keep an eye on your feed rates and cutting speeds. Slower speeds can help calm those rowdy vibrations. Think of it like driving a car; slow and steady wins the race!

| Best Practices | Description |

|---|---|

| Tool Geometry | Select tools with the right angles for cutting smoothness. |

| Material Selection | Use suitable materials to avoid mismatched vibrations. |

| Feed Rates | Adjust speed to minimize chatter and enhance precision. |

Remember, a smooth operation leads to a happy lathe and a happy you!

Environmental Considerations

Importance of a controlled environment in reducing vibration. Effects of foundation and machine placement on lathe performance.A controlled environment is vital for reducing lathe vibration. Vibration can lead to mistakes during metalworking. Placing the lathe on a stable foundation helps it perform better. A solid base keeps the machine steady and focused. Proper placement away from heavy machinery is also key. This minimizes disturbances. Remember, small changes in the environment can make a big difference. A well-set workspace leads to smoother operations.

Why Does Environment Matter for Lathe Performance?

An effective setup reduces errors, improves quality, and enhances safety. Each factor plays a role in how well a lathe functions. Simple adjustments can significantly impact outcomes.

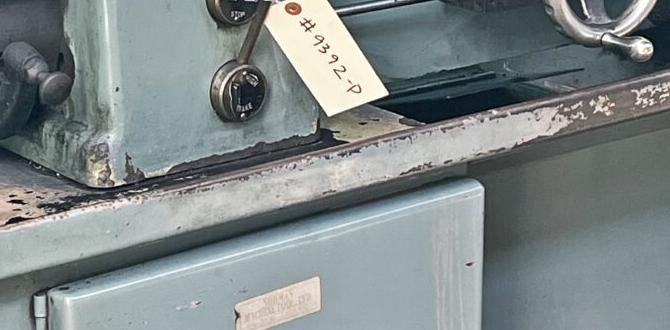

Case Studies and Real-World Applications

Examination of how industries successfully implemented vibration reduction. Lessons learned from failure cases due to inadequate vibration management.Many industries have tackled vibration issues with great creativity. For example, the automotive sector installed special mats to reduce lathe vibrations. This led to smoother cuts and happier workers. But not everyone enjoyed success. Some factories ignored vibration management, resulting in broken tools and wasted metal. Oops! They learned the hard way that vibration control is key. Balance is important, or you might find your projects wobbling like jelly on a plate!

| Industry | Success | Failure |

|---|---|---|

| Automotive | Reduced noise with mats | Ignored vibrations; tool breakage |

| Aerospace | Enhanced precision | Missed deadlines due to wobble |

Future Trends in Lathe Vibration Reduction

Emerging technologies and research focused on vibration control. Predictions for the future of precision machining and vibration management.The world of machining is buzzing with exciting ideas for fighting lathe vibrations. New technologies, like smart sensors and advanced software, help monitor and reduce these vibrations. In the future, we might even see machines that can talk to each other—like a family gathering but with less arguing! Research suggests that as we perfect vibration control, **precision machining** will improve, leading to better products and happier workers. As they say, “Less wobble, more gobble!”

| Emerging Technology | Benefits |

|---|---|

| Smart Sensors | Detect vibrations in real-time |

| Advanced Software | Predicts and reduces vibrations |

| Machine Communication | Enhances production efficiency |

Conclusion

In conclusion, reducing lathe vibration during metal lathe taper turning is crucial for better results. You can achieve smoother finishes and more accurate cuts by stabilizing your machine and using the right tools. Remember to check your setup regularly. For more tips on improving your lathe work, explore guides and videos online to enhance your skills.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction In The Context Of Taper Turning On A Metal Lathe:When you use a lathe to shape metal, sometimes it shakes or vibrates. This can make it hard to get a nice, smooth shape. To reduce this shaking, you can check if the lathe is set up right and tighten any loose parts. You can also use tools that are specially designed to reduce vibration. When the lathe runs smoothly, you’ll get better results with your taper turning!

Sure! Please ask your question, and I’ll be happy to answer it!

What Techniques Can Be Employed To Minimize Vibrations During Taper Turning Operations On A Metal Lathe?To reduce vibrations while taper turning on a metal lathe, you can do a few things. First, make sure the lathe is stable and not wobbly. You can also use sharp cutting tools, as they cut cleanly and cause less shaking. Slowing down the speed of the lathe helps too. Finally, adding weight to the lathe can help keep it steady while you’re working.

How Does The Choice Of Cutting Tools And Materials Affect Vibration Levels During The Taper Turning Process?The cutting tools you use can change how much a machine shakes when making a taper. If you pick a strong tool, it helps reduce vibration. Some materials are better at holding steady and making smoother cuts. If there’s less vibration, the finished project looks nicer. So, good tools and materials help keep things calm while you work.

What Role Does The Lathe’S Setup And Alignment Play In Reducing Vibrations When Performing Taper Turning?When using a lathe to make a tapered shape, how we set it up is very important. If it’s not aligned right, the machine shakes, which can mess up the work. We want the tool and the piece to fit perfectly. This helps us make smooth cuts without bumps. Checking the setup helps keep everything steady and makes our work look better.

How Can The Use Of Damping Materials Or Devices Enhance Stability And Minimize Vibrations During Taper Turning On A Lathe?Using damping materials or devices helps absorb vibrations when you’re taper turning on a lathe. This makes the machine more stable. When the lathe is steady, it cuts better and smoother. You get cleaner shapes and less chance of mistakes. In short, these tools improve your work by reducing wobbles overall!

What Are Some Common Signs Of Excessive Vibration During Taper Turning, And How Can Operators Address These Issues Effectively?Some common signs of too much vibration during taper turning are loud noises, shaking machines, and poor surface finish. If you notice these signs, you can check the tool and workpiece. Make sure everything is tight and balanced. You might need to adjust the speed or feed of the machine. Keeping the area clear of debris can also help.