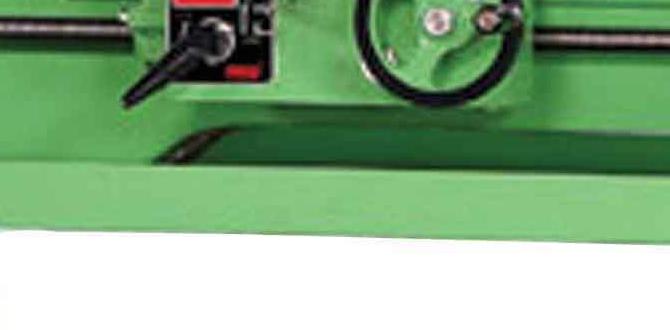

Have you ever wondered why a lathe sometimes shakes while you work? It can be frustrating when you just want to create something amazing. A metal lathe is a powerful tool that helps shape metals, but vibrations can mess up your projects. Imagine trying to thread a dial, only to find your work is uneven. This is where lathe vibration reduction comes into play.

Reducing vibration not only improves precision but also makes your projects smoother and more enjoyable. Think of it like riding a bike on a flat road versus a bumpy path. Which would you prefer? By learning how to manage these vibrations, you can unlock your lathe’s full potential.

Surprising fact: even small adjustments can lead to big changes in the quality of your work. Many users don’t realize how much a simple technique can help. So, are you ready to dive into the world of lathe vibration reduction and master your metal lathe threading dial?

Lathe Vibration Reduction: Enhancing Metal Lathe Threading Dial Performance

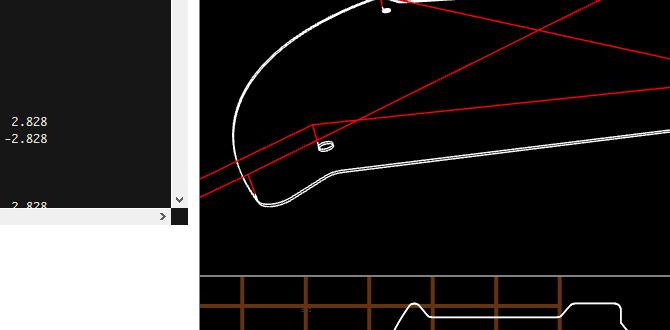

Lathe Vibration Reduction Metal Lathe Threading Dial

Reducing vibration on metal lathes is crucial for achieving precise threading. A stable machine provides smooth cuts and better quality results. When a lathe vibrates, it can lead to inaccurate measurements and poor finishes. Using a high-quality threading dial helps maintain accuracy, even during challenging tasks. Did you know that minimizing vibration can extend your machine’s lifespan? Implementing vibration reduction techniques keeps your projects on track and enhances overall performance.Understanding Lathe Vibration

Definition and significance of lathe vibration in machining processes. Common causes of vibration in metal lathes.Vibration in a lathe is an important factor in machining. It can affect the quality of the workpiece. Imagine trying to draw a straight line but your hand shakes! That’s similar to how vibration can disrupt the cutting process. Common causes of vibration include:

- Unbalanced tools

- Improper setup

- Worn bearings

These issues can lead to poor thread quality or a damaged machine. Understanding these causes helps operators make better choices and reduce vibration.

What is lathe vibration and why is it important?

Lathe vibration occurs during machining and affects performance. It can lead to mistakes and lower the quality of the final product. Recognizing vibration keeps machines running smoothly and safely.

Impact of Vibration on Threading Dial Performance

Effects of vibration on threading accuracy and surface finish. Relationship between vibration and tool wear.Vibration is not a friend to your threading dial. It makes everything wobbly, which can ruin your threading accuracy and make it as smooth as a bumpy road! When vibrations kick in, they can cause the finished surface to look like a rollercoaster ride. Plus, they wear down your tools quicker than eating candy at a party! Over time, this can lead to more frequent tool changes, costing you time and money. Keep those vibrations in check for a better finish!

| Effect | Impact |

|---|---|

| Threading Accuracy | Poor precision, uneven threads |

| Surface Finish | Bumpy, rough texture |

| Tool Wear | Increased wear, shorter lifespan |

Best Practices for Lathe Maintenance

Routine inspections and adjustments for optimal performance. Lubrication and its role in reducing vibration.Regular checks keep your lathe in top shape. Look for wear and tear on parts. Adjust them as needed for smooth operation. Lubrication is very important. Proper oil reduces vibration during use. Less vibration leads to better results.

- Check belts and pulleys often.

- Ensure clamps are tight.

- Oil moving parts daily.

- Clean machine after each use.

How often should I inspect my lathe?

Inspect your lathe weekly for best performance. Routine checks help catch problems early. Regular maintenance leads to longer machine life and better quality work.

Case Studies of Vibration Reduction Successes

Examples of industries employing effective vibration reduction techniques. Lessons learned from successful implementations.Many industries have found ways to reduce vibration successfully. For example, the automotive industry uses vibration dampers. These tools help ensure smoother operations. The aviation sector adopts balanced machinery to lessen vibrations during flights.

Lessons from these successes show that testing and adjustments are key. Companies learned that a strong foundation for machines is vital. Regular maintenance also prevents problems.

- Automotive: Vibration dampers

- Aviation: Balanced machinery

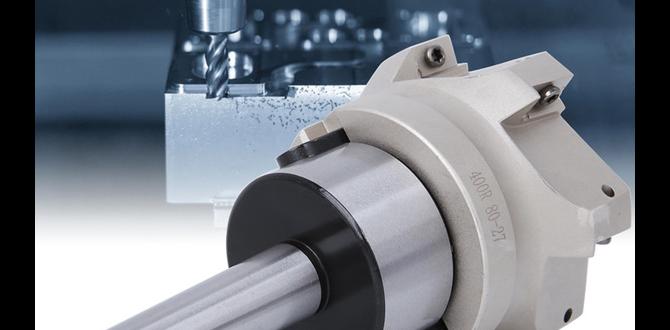

- Manufacturing: Advanced CNC tools

What are some successful vibration reduction examples?

Automakers use dampers, while aircraft makers opt for balanced machinery.

Future Trends in Lathe Vibration Management

Innovations in lathe technology aimed at reducing vibration. Emerging research and methodologies in vibration studies.New inventions are sprucing up lathe machines, making them quieter and smoother. Imagine running a lathe that hums a lovely tune instead of shaking like a maraca! Engineers are studying vibration-reducing materials that absorb bumps and shakes. Plus, smart technology is helping machines learn from their vibrations. This research isn’t just cool; it’s key for precision work. Soon, we’ll have lathes that practically dance while threading metals!

| Innovation | Benefit |

|---|---|

| Smart Sensors | Reduces unnecessary vibrations |

| New Materials | Absorbs shocks |

| Adaptive Algorithms | Improves threading accuracy |

Conclusion

In conclusion, reducing lathe vibration helps improve your metal lathe threading results. You can adjust speeds or add dampeners to minimize vibrations. A stable setup leads to better accuracy. We encourage you to explore more about lathe techniques and tools for even greater improvements. Keep learning, and enjoy your lathe work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction In Metal Lathes, Specifically Focusing On Threading Dials:Lathe vibration can make it hard to thread metal smoothly. To reduce vibrations, you can balance the lathe better and tighten loose parts. Using a good support system for the lathe helps too. Look for strong, heavy bases to keep it steady. If you can, adjust the speed when threading to see what works best!

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.

What Are The Common Causes Of Vibration In Metal Lathes During Threading Operations, And How Can They Be Mitigated?Vibration in metal lathes during threading happens mostly because of unbalanced parts, dull tools, or loose nuts. You can fix this by making sure everything is tight and balanced. Using sharp tools will help too. Also, you can adjust the speed of the lathe to reduce shaking. Keeping the workspace clean and steady makes a big difference!

How Does The Design Of The Threading Dial On A Lathe Influence Vibration Levels And Threading Accuracy?The threading dial on a lathe helps you line up cuts for threading. If it is designed well, it makes spinning smooth, which lowers vibration. Less vibration means your thread comes out more accurate. A good design also makes it easier for you to see where to cut. Better cuts give you stronger and more precise threads.

What Materials Or Modifications Can Be Implemented To Reduce Vibrations In A Metal Lathe Setup While Using The Threading Dial?To reduce vibrations in a metal lathe, you can use heavier materials. Adding rubber feet or pads helps, too. You can also think about using a dampening material like foam to absorb shaking. Tightening all parts so they are securely fastened is another good idea. These changes will make your lathe run smoother when using the threading dial.

How Can The Alignment And Maintenance Of The Lathe Contribute To Reducing Vibrations During Threading Processes?When we keep the lathe aligned and well-maintained, it runs smoothly. This smooth running helps reduce vibrations. When the lathe vibrates less, it makes threading safer and more accurate. Making sure everything is tight and balanced helps our work turn out better. So, regular checking and fixing can really help!

Are There Specific Techniques Or Tools That Operators Can Use To Optimize Threading Performance And Minimize Vibration While Using A Lathe?Yes, there are ways to make threading on a lathe better and reduce vibrations. First, you can use sharp tools because they cut cleaner. Second, make sure your lathe is stable and secure. Adding weights can help keep it steady. Finally, you can adjust the speed to find the best setting for smooth cutting.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction In Metal Lathes, Specifically Focusing On Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe vibration can make it hard to thread metal smoothly. To reduce vibrations, you can balance the lathe better and tighten loose parts. Using a good support system for the lathe helps too. Look for strong, heavy bases to keep it steady. If you can, adjust the speed when threading to see what works best!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Vibration In Metal Lathes During Threading Operations, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibration in metal lathes during threading happens mostly because of unbalanced parts, dull tools, or loose nuts. You can fix this by making sure everything is tight and balanced. Using sharp tools will help too. Also, you can adjust the speed of the lathe to reduce shaking. Keeping the workspace clean and steady makes a big difference!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Threading Dial On A Lathe Influence Vibration Levels And Threading Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial on a lathe helps you line up cuts for threading. If it is designed well, it makes spinning smooth, which lowers vibration. Less vibration means your thread comes out more accurate. A good design also makes it easier for you to see where to cut. Better cuts give you stronger and more precise threads.”}},{“@type”: “Question”,”name”: “What Materials Or Modifications Can Be Implemented To Reduce Vibrations In A Metal Lathe Setup While Using The Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibrations in a metal lathe, you can use heavier materials. Adding rubber feet or pads helps, too. You can also think about using a dampening material like foam to absorb shaking. Tightening all parts so they are securely fastened is another good idea. These changes will make your lathe run smoother when using the threading dial.”}},{“@type”: “Question”,”name”: “How Can The Alignment And Maintenance Of The Lathe Contribute To Reducing Vibrations During Threading Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we keep the lathe aligned and well-maintained, it runs smoothly. This smooth running helps reduce vibrations. When the lathe vibrates less, it makes threading safer and more accurate. Making sure everything is tight and balanced helps our work turn out better. So, regular checking and fixing can really help!”}},{“@type”: “Question”,”name”: “Are There Specific Techniques Or Tools That Operators Can Use To Optimize Threading Performance And Minimize Vibration While Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are ways to make threading on a lathe better and reduce vibrations. First, you can use sharp tools because they cut cleaner. Second, make sure your lathe is stable and secure. Adding weights can help keep it steady. Finally, you can adjust the speed to find the best setting for smooth cutting.”}}]}