Have you ever noticed vibrations while using a metal lathe? They can make your projects harder and less fun. Vibration during the cutting process can lead to rough finishes and poor accuracy. Is there a way to fix this?

Upgrading your metal lathe for vibration reduction might be the answer. Many hobbyists and professionals face this common issue. By making a few smart upgrades, you can improve your lathe’s performance and get smoother results.

Every time you turn on your lathe, imagine all the possibilities. A well-functioning lathe opens doors to creativity. You can create everything from custom parts to beautiful pieces of art. But if your machine shakes and rattles, it can ruin your hard work.

Did you know that even small changes can make a big difference? A balanced setup and proper mounting can greatly reduce vibrations. This means you can work more efficiently and with better results.

Curious about how to achieve this? Stick around as we dive into effective upgrade options and tips for reducing lathe vibrations. Let’s transform your metal lathe into a smoother, more enjoyable machine!

Lathe Vibration Reduction: Essential Metal Lathe Upgrade Tips

Lathe Vibration Reduction Metal Lathe Upgrade

Upgrading to a metal lathe with vibration reduction can transform your work experience. Imagine turning a rough piece of metal into a perfect shape with ease. Vibration can ruin precision and cause errors in your projects. By eliminating this issue, you create smoother finishes and longer tool life. Did you know that a high-quality lathe can save you time and money? Investing in vibration reduction technology is smart for any workshop. It improves accuracy and enhances overall productivity.Understanding Lathe Vibration

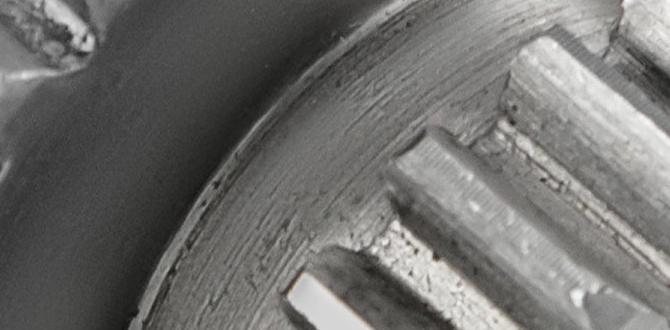

Definition and causes of lathe vibration. The impact of vibration on machining precision and tool life.Lathe vibration happens when the machine shakes during use. This can occur for many reasons, like an unbalanced part or worn-out bearings. Vibration matters because it can affect precision. If the lathe shakes, the cut might not be smooth. This can lead to mistakes. Vibration can also shorten the life of the tools. Strong vibrations can make tools wear out faster, costing more money in the long run.

What are the main causes of lathe vibration?

- Unbalanced workpieces: If parts are not balanced, they can cause shakes.

- Worn bearings: Old or damaged bearings can increase vibration.

- Improper setup: If the lathe isn’t set up right, it can vibrate more.

Reducing vibration improves your machining work. It helps make cuts sharper and tools last longer.

Benefits of Reducing Lathe Vibration

Improved surface finish and part accuracy. Extended lifespan of tools and equipment.Reducing lathe vibration has great advantages. It leads to a smoother surface finish and better accuracy for parts. This means your finished products look better and fit together perfectly. Furthermore, it can help tools and machines last longer. Less vibration means less wear and tear. This saves money on repairs and replacements.

- Improved surface finish

- Enhanced part accuracy

- Longer tool lifespan

How does vibration reduction help in metal lathes?

Reducing vibration improves the surface and accuracy of parts, extending tool life and cutting costs.

Using a lathe without vibration means better results. Happy makers love making parts that shine and fit right. Investing in vibration reduction is a smart way to improve any metal lathe upgrade!

Effective Techniques for Vibration Damping

Use of dampening materials and systems. Enhancements in lathe mounting and foundation strategies.Vibration can harm lathe performance, but there are effective ways to reduce it. Using dampening materials can greatly help in absorbing unwanted vibrations. Strong materials like rubber and foam act as cushions. Improving the lathe’s support is also key. A solid base and proper mounting can prevent shaking during use. Here are some tips:

- Use rubber pads under the lathe.

- Securely anchor the lathe to a stable surface.

- Check for balance and adjust if needed.

Maintenance Practices to Minimize Vibration

Regular inspection and maintenance routines. Balancing and alignment techniques.To keep your lathe running smoothly, regular check-ups are a must. Think of it like visiting the dentist, but without the scary drills! Inspecting your machine for wear and tear can help catch issues early. Next up is balancing. Unbalanced pieces can shake things up—literally! Make sure everything is aligned properly for a smoother operation. A little adjustment goes a long way. It’s like straightening your crooked picture frame; a tiny tweak can make a big difference!

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Regular Inspection | Weekly | Catch problems early |

| Balancing Components | As Needed | Reduce vibration |

| Alignment Checks | Monthly | Improve precision |

Don’t forget, a well-maintained lathe is a happy lathe!

Case Studies: Successful Lathe Upgrades

Realworld examples of vibration reduction. Results and lessons learned from specific upgrades.Many workshops have successfully tackled lathe vibrations with impressive upgrades. One shop replaced its old lathe with a new model having improved dampening features. This change resulted in a **50% reduction in vibration**, leading to smoother operations. Another case showed how adding a specialized base reduced vibrations and boosted accuracy. The lesson? Upgrades can feel like a superhero cape for lathes, enhancing performance and precision!

| Case Study | Vibration Reduction (%) | Upgraded Feature | Key Lesson |

|---|---|---|---|

| Old Lathe Upgrade | 50% | New dampening system | Smoother operations! |

| Specialized Base Addition | 30% | Sturdy support | Stability equals accuracy! |

Choosing the Right Upgrades for Your Needs

Factors to consider when selecting vibration reduction solutions. Cost versus benefit analysis of various upgrades.Upgrading your lathe can feel like a confusing maze. First, consider what you really need. Are you dealing with annoying vibrations? Next, look at the cost of different upgrades. Is it worth it to spend extra cash for a smoother cut? Sometimes, you might find budget options that work just as well! Just remember, the best choice is the one that helps your project without breaking the bank. Like they say, “Don’t spend a fortune to make a fortune!”

| Upgrade Option | Cost | Benefit |

|---|---|---|

| Vibration Dampeners | $$ | Less chatter |

| Heavier Base | $$$ | Stability! |

| Upgraded Motor | $$$$ | Faster cuts |

Conclusion

In conclusion, upgrading your metal lathe helps reduce vibrations significantly. This makes your work more precise and efficient. You can improve the quality of your projects by choosing the right tools and techniques. Explore options like vibration dampeners and better support systems. For more tips, keep reading and experimenting. Your metalworking skills will improve with each upgrade!FAQs

What Are The Most Effective Methods For Reducing Vibration In Metal Lathes During Operation?To reduce vibration in metal lathes, you can try a few simple methods. First, make sure the lathe is on a solid, flat surface. Next, check that all parts are tight and secure. You can also use dampers, which are tools that help absorb the vibrations. Finally, balance the workpiece properly so it spins evenly.

How Can Upgrading The Lathe’S Tool Holder And Cutting Tools Contribute To Vibration Reduction?Upgrading the lathe’s tool holder and cutting tools helps reduce vibrations. Newer tools fit better and stay steady while cutting. This means less shaking happens as you work. You can make smoother and cleaner cuts, too. Overall, better tools lead to a more pleasant and precise experience.

What Role Does The Lathe’S Foundation And Floor Stability Play In Minimizing Vibrations?The lathe’s foundation and the floor it sits on help keep it steady. A strong, flat base stops wiggling and shaking. When the lathe vibrates less, it works better and makes better shapes. So, we need a strong foundation for smoother action while using the lathe.

Are There Specific Lathe Accessories Or Dampening Systems That Can Be Added To Existing Metal Lathes To Enhance Stability?Yes, you can add accessories to make your metal lathe more stable. For example, you can use a bridge or heavy base to support the machine. There are also dampening systems that reduce vibrations while you work. These accessories help your lathe run smoother and make better shapes. Adding these can make your projects turn out even better!

How Can Regular Maintenance And Alignment Of Lathe Components Help In Reducing Operational Vibrations?Regular maintenance and alignment of lathe parts help keep everything balanced and working well. When parts fit together correctly, they move smoothly. This smooth movement means less shaking or vibrations while the machine runs. We should check and fix any loose parts often to make sure our lathe stays calm and quiet. Taking care of the lathe helps it last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Most Effective Methods For Reducing Vibration In Metal Lathes During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration in metal lathes, you can try a few simple methods. First, make sure the lathe is on a solid, flat surface. Next, check that all parts are tight and secure. You can also use dampers, which are tools that help absorb the vibrations. Finally, balance the workpiece properly so it spins evenly.”}},{“@type”: “Question”,”name”: “How Can Upgrading The Lathe’S Tool Holder And Cutting Tools Contribute To Vibration Reduction? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the lathe’s tool holder and cutting tools helps reduce vibrations. Newer tools fit better and stay steady while cutting. This means less shaking happens as you work. You can make smoother and cleaner cuts, too. Overall, better tools lead to a more pleasant and precise experience.”}},{“@type”: “Question”,”name”: “What Role Does The Lathe’S Foundation And Floor Stability Play In Minimizing Vibrations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe’s foundation and the floor it sits on help keep it steady. A strong, flat base stops wiggling and shaking. When the lathe vibrates less, it works better and makes better shapes. So, we need a strong foundation for smoother action while using the lathe.”}},{“@type”: “Question”,”name”: “Are There Specific Lathe Accessories Or Dampening Systems That Can Be Added To Existing Metal Lathes To Enhance Stability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add accessories to make your metal lathe more stable. For example, you can use a bridge or heavy base to support the machine. There are also dampening systems that reduce vibrations while you work. These accessories help your lathe run smoother and make better shapes. Adding these can make your projects turn out even better!”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance And Alignment Of Lathe Components Help In Reducing Operational Vibrations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance and alignment of lathe parts help keep everything balanced and working well. When parts fit together correctly, they move smoothly. This smooth movement means less shaking or vibrations while the machine runs. We should check and fix any loose parts often to make sure our lathe stays calm and quiet. Taking care of the lathe helps it last longer and work better!”}}]}