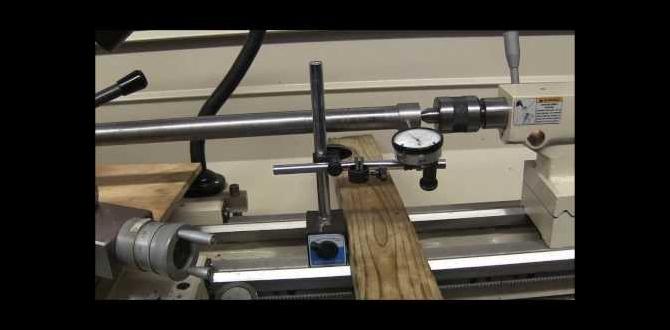

Have you ever watched a metal lathe in action? It’s fascinating! This powerful machine can shape metal into incredible designs. But did you know that the way you wire your lathe is just as important as its features?

Imagine trying to create a perfect piece without the right setup. If your lathe wiring isn’t done well, you might face problems. A poorly wired lathe can even be dangerous!

Setting up your lathe on a sturdy metal lathe bench makes a huge difference too. A solid bench helps keep your machine steady and safe. It can improve your work quality and make the process a lot easier.

In this article, we will explore how to wire your lathe correctly. We will also talk about the best practices for using a metal lathe bench. Get ready to turn your projects into amazing creations!

Lathe Wiring For Your Metal Lathe Bench Setup Guide

Understanding Lathe Wiring for Your Metal Lathe Bench

Lathe wiring is key to operating your metal lathe safely and efficiently. Knowing how to set up your lathe bench can save time and reduce headaches. Have you ever wondered what happens if your wiring goes wrong? It can lead to short circuits or worse. By learning about proper wire connections and safety tips, you ensure smoother operations. Plus, understanding these aspects helps you troubleshoot common issues, making lathe work more enjoyable.Choosing the Right Power Supply

Types of power supplies suitable for metal lathes. Voltage and amperage considerations.Selecting the right power supply for your metal lathe can feel like picking the perfect snack on movie night—critical but often tricky! You’ll need to match voltage and amperage to keep your lathe happy. Common choices include AC or DC power supplies, each serving a unique purpose. Make sure to check the specifications of your lathe for the right fit. Remember, too little power can make your lathe sluggish, like a sleepy cat on a warm day! Here’s a quick comparison table:

| Type | Voltage | Amperage |

|---|---|---|

| AC Supply | 120V | 5-10A |

| DC Supply | 24V | 10-20A |

Choose wisely, and you’ll be turning metal like a pro in no time!

Essential Tools for Lathe Wiring

List of necessary tools for the wiring process. Safety equipment and precautions.To wire a lathe safely, you need some important tools. Here’s a quick list:

- Wire cutters

- Wire strippers

- Screwdrivers

- Electrical tape

- Multimeter

Don’t forget safety gear. Always wear:

- Safety goggles

- Gloves

- Ear protection

Following these guidelines will help keep you safe while you work.

What is the most important safety tip for lathe wiring?

Always disconnect the power before starting any wiring project.

Step-by-Step Wiring Process

Detailed wiring instructions for 120V and 240V lathes. Tips for connecting the motor and controls.Wiring your lathe can be easy! First, plug in safely with a 120V or 240V setup. Here is how you can do it:

- For 120V lathes, connect the black wire to the motor terminal and the white wire to the neutral terminal.

- For 240V lathes, connect two hot wires. These are usually black and red.

- Always attach a ground wire for safety.

Tips for connecting the motor:

- Follow the labels on the motor carefully.

- Double-check all connections before turning on the power.

Testing the setup can prevent costly mistakes. Stay safe and have fun with your lathe!

How do I wire a lathe correctly?

Start by following the steps carefully. Choose the right voltage setting and follow wiring diagrams. Make sure you check connections to ensure safety.

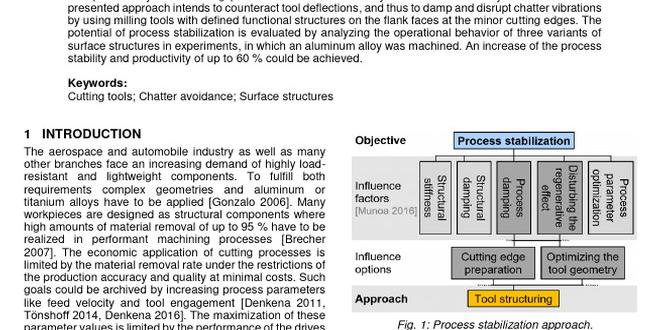

Wiring Diagram Examples

Common wiring diagrams for different metal lathe models. Explanation of each component in the diagrams.Wiring diagrams help us understand how to connect parts of a metal lathe. Each diagram shows different lathe models. They highlight key components like the motor, switches, and power supply. Knowing these parts makes wiring easier. Common elements in the diagrams include:

- Motor: Drives the lathe tool.

- Switch: Turns the lathe on or off.

- Power supply: Provides electricity.

By studying these diagrams, users can wire their metal lathe correctly. It’s like following a treasure map!

What do wiring diagrams show for metal lathes?

Wiring diagrams show how to connect parts of metal lathes. They make it easy to see where each wire goes. This ensures the lathe runs safely and smoothly. Understanding these diagrams is essential for troubleshooting and maintenance.

Troubleshooting Common Wiring Issues

Identifying symptoms of wiring problems. Solutions for common wiring faults.Wiring problems can slow down your metal lathe bench. Look for signs like flickering lights or machines not starting. These symptoms often mean there’s a wiring issue. Common faults can come from loose connections or damaged wires. Here are some solutions:

- Check connections: Make sure all wires are tight and secure.

- Inspect for damage: Look for cuts or frayed wires.

- Test with a multimeter: Check for accurate voltage and continuity.

Keeping tools in good shape helps you work better.

What are the signs of wiring problems?

Some signs include machines not turning on, strange noises, or overheating. Look closely, and you’ll notice these clues!

Maintenance and Safety Tips

Regular inspection routines for lathe wiring. Safety practices to prevent electrical hazards.Checking your lathe wiring is like brushing your teeth. It keeps things running smoothly and avoids nasty surprises. Start by looking at the wires for cracks or frays. A tiny nick can cause big problems, like sparks flying out of nowhere! For safety, always unplug your lathe before inspecting it. Remember, safety first, fun later! Here’s a handy reminder table:

| Tip | Description |

|---|---|

| Check Wires | Look for damage regularly. |

| Unplug Before Inspection | Avoid shocks while you check. |

| Use Circuit Breakers | These can save your bacon! |

Following these practices helps keep your workspace safe and sound. Like wearing a helmet while riding a bike, it’s just smart! No one wants a shocking experience, right?

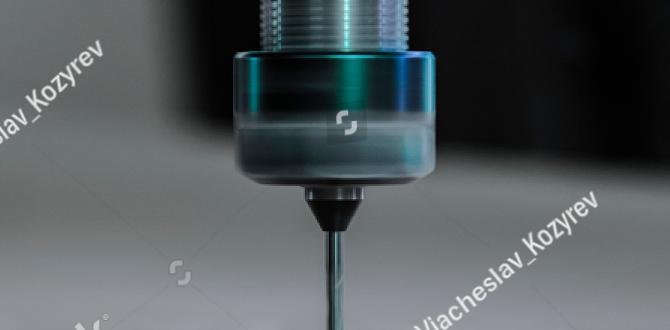

Upgrading Your Lathe Wiring

Benefits of upgrading wiring for performance. Recommended upgrades for efficiency and safety.Upgrading the wiring of your lathe can make a big difference in how well it works. Better wiring helps your lathe run smoothly. This means you can create precise cuts and finish your projects faster. Here are some benefits of upgrading:

- Improved Safety: New wiring reduces risk of electric shock.

- Enhanced Efficiency: Your lathe will use less energy while working.

- Longer Lifespan: Stronger wiring prevents wear and tear.

You might consider using thicker gauge wire and quality connectors. These upgrades ensure strong connections and reliable performance. Small changes can lead to amazing improvements!

What are the benefits of upgrading lathe wiring?

Upgrading lathe wiring boosts performance and safety. It helps achieve clean cuts, saves energy, and lowers the risk of accidents.

Conclusion

In summary, understanding lathe wiring for your metal lathe bench is crucial for safe and effective use. Proper wiring helps prevent accidents and improves performance. You should always follow safety guidelines and instructions. If you’re ready to start, check out tutorials and manuals for practical tips. With the right knowledge, you’re on your way to becoming a skilled lathe operator!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Benches:Sure! A lathe is a machine used to shape metal or wood. When wiring a lathe, you need to connect it safely to electricity. Make sure the power is off before you start. You should also use a strong bench to hold the lathe in place. It helps to keep everything steady while you work.

Sure! Just ask your question and I’ll provide an answer for you.

What Are The Essential Electrical Components Needed For Wiring A Metal Lathe?To wire a metal lathe, you need a motor, switches, and wires. The motor makes the lathe turn. Switches help you turn the lathe on and off. Wires connect everything together so electricity flows. Don’t forget a plug to connect to the power outlet!

How Do You Determine The Appropriate Wire Gauge For Connecting A Metal Lathe To A Power Source?To choose the right wire size for a metal lathe, you first need to know how much power it uses. Look at the lathe’s electrical rating, usually given in amps (A). Then, check a wire gauge chart that tells you which size can handle that much power safely. Make sure to pick a wire a little bigger if your lathe will run for a long time or in a hot place. This helps keep everything safe and working well!

What Safety Precautions Should Be Taken When Wiring A Metal Lathe Bench?When wiring a metal lathe bench, you should always unplug the machine before you start. Use proper tools and wear rubber gloves to protect yourself. Make sure your workspace is dry and free from water. Check the wires for damage to prevent shocks. Finally, have a buddy nearby in case you need help.

How Can You Troubleshoot Electrical Issues Related To A Metal Lathe’S Wiring?To fix electrical problems with a metal lathe, first, turn off the power. Check the wires for any damage or loose connections. You can use a flashlight to see better. If something looks broken, ask an adult for help. Finally, test the machine again to see if it works.

What Type Of Power Supply Is Recommended For Different Sizes Of Metal Lathes, And How Does This Affect Wiring Configurations?For small metal lathes, we usually use a 110-volt power supply. For larger lathes, a 220-volt supply is better. The size of the lathe affects how we set up the wires. Bigger machines need thicker wires to handle more power safely. Always make sure the wires match the lathe size you are using!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Benches:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine used to shape metal or wood. When wiring a lathe, you need to connect it safely to electricity. Make sure the power is off before you start. You should also use a strong bench to hold the lathe in place. It helps to keep everything steady while you work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question and I’ll provide an answer for you.”}},{“@type”: “Question”,”name”: “What Are The Essential Electrical Components Needed For Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a motor, switches, and wires. The motor makes the lathe turn. Switches help you turn the lathe on and off. Wires connect everything together so electricity flows. Don’t forget a plug to connect to the power outlet!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Wire Gauge For Connecting A Metal Lathe To A Power Source?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right wire size for a metal lathe, you first need to know how much power it uses. Look at the lathe’s electrical rating, usually given in amps (A). Then, check a wire gauge chart that tells you which size can handle that much power safely. Make sure to pick a wire a little bigger if your lathe will run for a long time or in a hot place. This helps keep everything safe and working well!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe bench, you should always unplug the machine before you start. Use proper tools and wear rubber gloves to protect yourself. Make sure your workspace is dry and free from water. Check the wires for damage to prevent shocks. Finally, have a buddy nearby in case you need help.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Electrical Issues Related To A Metal Lathe’S Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix electrical problems with a metal lathe, first, turn off the power. Check the wires for any damage or loose connections. You can use a flashlight to see better. If something looks broken, ask an adult for help. Finally, test the machine again to see if it works.”}},{“@type”: “Question”,”name”: “What Type Of Power Supply Is Recommended For Different Sizes Of Metal Lathes, And How Does This Affect Wiring Configurations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For small metal lathes, we usually use a 110-volt power supply. For larger lathes, a 220-volt supply is better. The size of the lathe affects how we set up the wires. Bigger machines need thicker wires to handle more power safely. Always make sure the wires match the lathe size you are using!”}}]}