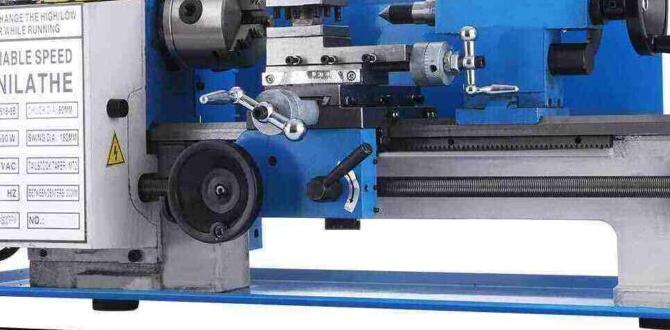

Have you ever wondered how metal parts are perfectly shaped? A lathe is a magical tool that spins metal to create smooth shapes. But what keeps it running smoothly? The answer lies in the lathe wiring.

Imagine trying to fix a bike without the right tools. It wouldn’t be easy, right? Just like that, without proper lathe wiring, your lathe can’t work well. And what about the chuck key? This small but mighty tool helps you secure materials on the lathe. Without it, your metal might slip or move, ruining your hard work!

Did you know that a simple chuck key mistake can lead to big problems? It’s true! Understanding lathe wiring and the purpose of the metal lathe chuck key is crucial for anyone who wants to create beautiful projects. Let’s dive deeper into these essential tools and learn how they can change your crafting game!

Lathe Wiring: Understanding Metal Lathe Chuck Key Usage

Did you know that a lathe can turn raw metal into amazing shapes? Proper lathe wiring ensures safety and efficiency when working. A metal lathe chuck key is crucial for securing materials tightly. Without it, your project could go wrong. When using a chuck key, remember to keep it near your lathe to avoid losing it. Proper usage leads to great results. So, next time you work on your lathe, think of these key aspects to enhance your skills!

Basics of Lathe Wiring

Explanation of lathe wiring components. Common wiring configurations for metal lathes.

In a lathe, wiring is crucial. It connects power to different parts, ensuring they work together. The main components include:

- Power Supply: Provides energy.

- Motor: Drives the spindle.

- Switch: Turns the lathe on and off.

- Wire Connections: Links all parts securely.

Common wiring setups for metal lathes might include single-phase or three-phase systems. Each offers unique strengths. Understanding these parts and setups helps you use your lathe safely and effectively.

What is the role of wiring in a lathe?

The wiring in a lathe sends power to make it run. It connects the motor and tools so they can create things. A good wiring setup helps the lathe work well.

Essential Tools for Lathe Wiring

List of tools required for wiring a lathe. Safety gear and precautions while wiring.

Wiring a lathe requires some important tools. Having the right tools makes the job smooth and safe. Here’s a quick list:

- Wires and connectors

- Wire stripper

- Screwdriver set

- Insulation tape

- Multimeter

- Lathe wiring diagram

Safety is key. Always wear safety glasses and gloves. Ensure the lathe is unplugged before starting. Follow these steps for a successful wiring project.

What safety gear is needed for lathe wiring?

Use safety glasses to protect your eyes and gloves to keep your hands safe. A dust mask can also help if you’re working with a lot of dust.

Step-by-Step Guide to Wiring a Metal Lathe

Detailed wiring instructions. Troubleshooting common wiring issues.

Wiring a metal lathe can seem tricky, but with some simple steps, you’ll be a wiring pro in no time! First, connect the power supply to the control panel; make sure to match the colors. If wires get tangled, remember, they are not spaghetti! Next, attach the motor wires to the appropriate terminals. If your lathe isn’t spinning, double-check your connections like a detective on a mission. Use the table below for wiring guidance:

| Component | Wiring Color |

|---|---|

| Power Supply | Black |

| Motor | Red |

| Ground | Green |

Lastly, if something goes wrong, don’t worry! Simple issues can often be fixed by checking connections again. Remember, a well-wired lathe is a happy lathe!

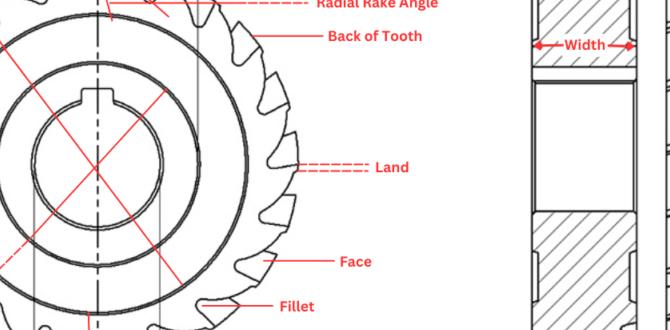

Importance of Using the Right Chuck Key

Consequences of using the wrong chuck key. Recommendations for choosing a chuck key for specific lathes.

Using the wrong chuck key can lead to trouble. It might not fit, which means your work might get wobbly. Ever try to screw in a light bulb with a garden rake? Exactly! It’s messy and could damage your lathe. Choose the right one by looking at the size and style for your specific lathe. Remember, a chuck key is like a key to a treasure chest; use the right one to keep your treasures safe!

| Lathe Type | Recommended Chuck Key Size |

|---|---|

| Mini Lathe | 3/8 inch |

| Standard Lathe | 1/2 inch |

| Heavy-Duty Lathe | 5/8 inch |

Choosing wisely keeps your projects running smoothly. Remember, choose a chuck key that fits like a glove. Measure twice, chuck key once!

Maintenance Tips for Chuck Keys

How to properly maintain and care for your chuck key. Signs of wear and when to replace your chuck key.

To keep your chuck key working well, take good care of it. Store it in a dry place to prevent rust. Check for signs of wear, like cracks or bends. If you notice these issues, it’s time to replace your chuck key. A worn key can cause problems with your lathe. Remember, a smooth lathe operation starts with a well-maintained key!

- Store in a dry area

- Look for cracks or bends

- Replace if damaged

How do I know when to replace my chuck key?

Signs of wear include visible cracks, unusual noise, or difficulty tightening. If you see these, get a new key!

Upgrading Your Lathe Wiring and Chuck Key

Benefits of upgrading wiring and chuck key. Suggested upgrades for improved performance and safety.

Upgrading the wiring and chuck key on your lathe can lead to great benefits. Improved wiring enhances safety by reducing the risk of electrical issues. A new chuck key makes changing tools easier and faster. This boosts your project efficiency. Consider the following upgrades:

- High-quality insulated wiring for safety

- Ergonomic chuck key for better grip

- Upgraded power supply for smoother operation

Why should I upgrade my lathe wiring and chuck key?

Upgrading increases safety, efficiency, and overall performance. Quality equipment minimizes accidents and speeds up work.

Conclusion

In summary, understanding lathe wiring and the metal lathe chuck key is essential for smooth operation. The chuck key helps you secure your workpiece firmly. Always check your wiring for safety and efficiency. We encourage you to practice using your lathe and read more about its parts. This knowledge will help you become a better craftsman!

FAQs

What Is The Proper Way To Wire A Metal Lathe For Optimal Performance And Safety?

To wire a metal lathe safely, start by turning off the power. Use the right wires that match the machine’s needs. Connect the wires according to the instructions. Make sure all connections are tight and secure. Always check your work before plugging it in. Safety first!

How Do I Choose The Right Chuck Key For My Specific Metal Lathe Model?

To choose the right chuck key for your metal lathe, first, check the size of your chuck. The chuck is the part that holds the tools. You can find this size in your metal lathe’s manual. If you don’t have the manual, you can measure the chuck’s hole. Finally, buy a chuck key that matches that size.

What Are The Common Issues Related To Lathe Wiring, And How Can They Affect The Operation Of The Lathe Chuck?

Common issues with lathe wiring include loose connections and damaged wires. If the wires are not connected well, the lathe may not work right. This can cause the chuck, which holds the material, to spin too slowly or not at all. It’s important to check the wiring to keep everything running smoothly. You want the lathe to work properly for your projects!

Can Improper Use Of A Chuck Key Lead To Damage In A Metal Lathe? If So, How?

Yes, using a chuck key wrong can hurt a metal lathe. A chuck key helps hold tools tightly. If you don’t use it properly, the tool can slip or even fall out. This might cause parts of the lathe to get bent or damaged. Always be careful when using the chuck key to keep everything safe!

What Safety Precautions Should I Take When Working With Lathe Wiring And Using A Chuck Key?

When working with a lathe, always unplug it before touching any wires. This keeps you safe from electric shocks. When using the chuck key, never leave it in the chuck after use; take it out right away. Also, wear safety goggles to protect your eyes from flying bits. Lastly, keep your hands clear of moving parts to avoid injury.