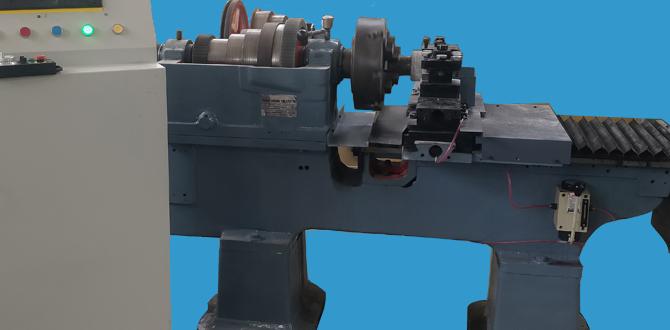

Have you ever wondered how machines like lathes work? These mighty tools shape metal into various forms. But did you know that you can upgrade your old metal lathe? It’s true! Many people are now converting their manual lathes into CNC machines. This process is called retrofitting.

When we talk about lathe wiring, things can seem complicated. But with a little guidance, anyone can do it. Imagine transforming a basic metal lathe into a smart, computer-controlled machine. The results can be amazing!

It’s like giving your tools a brain! Picture this: you simply input your desired shape, and the lathe does the rest. Sounds cool, right? Let’s dive into how lathe wiring can make this upgrade possible. It might be easier than you think!

Lathe Wiring For Metal Lathe Cnc Retrofit Guide

Understanding Lathe Wiring for CNC Retrofit

Lathe wiring is crucial for retrofitting metal lathes with CNC capabilities. Many hobbyists and professionals seek to upgrade older machines for precision. The process involves connecting motors and controllers properly. This enhances the lathe’s performance and accuracy. Did you know that a well-wired CNC lathe can save you time and material? With proper wiring, users can improve their machining skills and create intricate designs effortlessly. Dive into this upgrade and unlock your machine’s potential!Understanding Lathe Wiring Basics

Definitions of key terms related to lathe wiring. Importance of proper wiring in CNC retrofitting.Understanding lathe wiring is crucial for anyone using a CNC machine. Key terms include:

- CNC: Computer Numerical Control, which automates your machine.

- Wire Gauge: Measures the thickness of the wire used.

- Voltage: The electrical force that drives your machine.

Proper wiring is essential for safety and efficiency. It helps prevent malfunctions and keeps your machine running smoothly. Poor wiring can lead to damage or unsafe conditions.

Why is proper wiring important?

Proper wiring ensures safe operation, prevents errors, and maximizes performance. Good wiring supports the longevity of your CNC system. Remember, a well-wired machine works better.Wiring Diagrams for Metal Lathes

Detailed breakdown of standard wiring diagrams. Explanation of color codes and symbols used in diagrams.Wiring diagrams are like treasure maps for metal lathes. They guide you through the maze of connections. A typical diagram shows where each wire goes. Colors are not just for fun; they mean different things! For example, red can signal power while blue might mean neutral. Knowing these codes helps avoid shocking surprises—like finding your cat in the toolbox.

| Color Code | Meaning |

|---|---|

| Red | Power |

| Black | Neutral |

| Green | Ground |

| Blue | Control |

Also, symbols are like secret emojis that help you understand how everything fits together. Follow these diagrams carefully, and you might just create a masterpiece instead of a metal spaghetti monster!

Step-by-Step Wiring Process for CNC Retrofit

Prewiring preparation and safety measures. Detailed wiring steps from power supply to motors.Before wiring your CNC retrofit, safety is key. First, turn off all power sources. Use insulated tools to avoid shocks. Clear the area of any clutter. Make sure you wear safety gear like gloves and goggles. Once you’re ready, follow these wiring steps:

- Connect your power supply to the control board.

- Install the motors, linking them to the control board.

- Wire the limit switches to prevent over-travel.

- Secure all connections and tidy up the wires.

This process ensures a safe and effective conversion for your metal lathe.

What safety measures should I take before wiring?

Always turn off the power first. Make sure to wear safety gear and use insulated tools. Clear workspaces help prevent accidents.

Troubleshooting Common Wiring Issues

Identification of common wiring problems. Solutions and tips for effective troubleshooting.Wiring problems can feel like a maze, but finding them isn’t so tricky! Common issues include loose connections, frayed wires, or wrong wiring colors. A flickering light might signal a bad connection, while strange noises can hint at more trouble. To tackle these snags, check your connections first. Always make sure to turn off the power before poking around!

| Problem | Possible Cause | Solution |

|---|---|---|

| Loose Connection | Wires not tightly connected | Reconnect and tighten |

| Frayed Wires | Wear and tear | Replace damaged wires |

| Wrong Colors | Improper connections | Follow wiring diagrams |

Remember, if it smells funny, something’s not right! Troubleshooting wiring issues can save you time and prevent big repairs later. It’s better to be a wiring wizard than a confused muggle!

Best Practices for Lathe Wiring Maintenance

Routine maintenance checks and procedures. Signs of wear or damage to look for in wiring.Taking care of your lathe wiring is very important. Regular checks keep everything running smoothly. Look for signs of wear, like frayed wires or broken connectors. These can cause problems later. Always inspect your wiring connections. Here are some key maintenance tips:

- Check wires for cuts or tears.

- Ensure connections are tight and rust-free.

- Look for exposed wires that could cause shorts.

Following these simple steps can help avoid bigger issues. Remember, a well-maintained lathe can last longer and work better!

What should I look for during maintenance checks?

Check for any signs of damage. This includes:

- Frayed wires, which can lead to shorts.

- Loose connections, which may create inconsistent power.

Frequently Asked Questions (FAQs)

Answers to common queries about lathe wiring and retrofitting. Tips for beginners venturing into CNC retrofitting.Many people wonder about lathe wiring and retrofitting. It can feel like a puzzle! One common question is, “Can I do this myself?” The answer is yes, with some practice and patience. Beginners should start by reading manuals, watching videos, and not be afraid to ask for help. It’s like learning to ride a bike—you might fall a few times, but soon you’ll be zooming around!

| Common Questions | Answers |

|---|---|

| What tools do I need? | Basic hand tools and a multimeter. |

| Is retrofitting worth it? | Absolutely! It can save money and time. |

Learning about lathe wiring can be fun! Remember, if you mess up, it’s not the end of the world. You’re not alone—just think of all the happy accidents that led to new discoveries!

Conclusion

In summary, a lathe wiring CNC retrofit transforms your metal lathe into a modern, efficient tool. You learn to connect electronics safely and improve precision in your projects. This upgrade can boost your skills and creativity. If you’re interested, explore more tutorials or guides. With some practice, you can enjoy the benefits of a CNC lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring For A Cnc Retrofit:Sure! First, let’s talk about what a CNC retrofit is. A CNC, or Computer Numerical Control, helps machines like lathes work better. When we do a retrofit, we change old parts to make the machine smarter and more precise. Think of it as giving your toy a cool new upgrade! Lathes need special wiring to connect all the parts properly for this upgrade.

Sure! Please provide the question you would like me to answer.

What Are The Essential Components Required For Wiring A Metal Lathe During A Cnc Retrofit?To wire a metal lathe for a CNC retrofit, you need a few key parts. First, get a power supply to give energy to the machine. Next, use a motor controller to control how fast the lathe spins. You will also need wires to connect everything and connectors to join the wires. Finally, don’t forget safety switches to keep everything safe while you work.

How Do You Determine The Appropriate Stepper Or Servo Motors For Your Lathe Cnc Retrofit Project?To choose the right stepper or servo motors for your lathe CNC retrofit project, start by checking the size of your lathe. You need motors that can handle the weight and power needed. Next, think about how fast you want the lathe to move. Faster motors help with speed, while stronger motors help with heavy jobs. Finally, look for motors that match your machine’s controls. This helps everything work smoothly together.

What Wiring Techniques Should Be Used To Ensure Safety And Reliability In A Cnc Retrofitted Metal Lathe?To keep your CNC retrofitted metal lathe safe, use proper wires with good insulation. Make sure all wires are connected tight and nothing is loose. You should also use fuses to protect against too much electricity. Always follow safety guidelines and wear protective gear while working. Remember to check everything regularly to prevent problems.

How Do You Configure And Connect The Motor Drivers To The Control Board In A Cnc Lathe Retrofit?To connect motor drivers to the control board in a CNC lathe, you start by matching the wires. First, you find the right wires on the motor drivers and the control board. Next, you connect them carefully, following the colors or labels. Once all the wires are connected, you check everything to make sure it’s right. Finally, you power it on and test to see if it works!

What Troubleshooting Steps Can Be Taken If A Cnc Retrofitted Lathe Experiences Wiring Malfunctions Or Communication Issues?If your CNC retrofitted lathe has wiring problems, first check all the wires. Make sure they’re connected tightly and not damaged. Next, look at the control box for any loose connections. If it’s a communication issue, restart the machine and computer. If the problems keep happening, ask someone with more experience for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring For A Cnc Retrofit:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! First, let’s talk about what a CNC retrofit is. A CNC, or Computer Numerical Control, helps machines like lathes work better. When we do a retrofit, we change old parts to make the machine smarter and more precise. Think of it as giving your toy a cool new upgrade! Lathes need special wiring to connect all the parts properly for this upgrade.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Required For Wiring A Metal Lathe During A Cnc Retrofit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe for a CNC retrofit, you need a few key parts. First, get a power supply to give energy to the machine. Next, use a motor controller to control how fast the lathe spins. You will also need wires to connect everything and connectors to join the wires. Finally, don’t forget safety switches to keep everything safe while you work.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Stepper Or Servo Motors For Your Lathe Cnc Retrofit Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right stepper or servo motors for your lathe CNC retrofit project, start by checking the size of your lathe. You need motors that can handle the weight and power needed. Next, think about how fast you want the lathe to move. Faster motors help with speed, while stronger motors help with heavy jobs. Finally, look for motors that match your machine’s controls. This helps everything work smoothly together.”}},{“@type”: “Question”,”name”: “What Wiring Techniques Should Be Used To Ensure Safety And Reliability In A Cnc Retrofitted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your CNC retrofitted metal lathe safe, use proper wires with good insulation. Make sure all wires are connected tight and nothing is loose. You should also use fuses to protect against too much electricity. Always follow safety guidelines and wear protective gear while working. Remember to check everything regularly to prevent problems.”}},{“@type”: “Question”,”name”: “How Do You Configure And Connect The Motor Drivers To The Control Board In A Cnc Lathe Retrofit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To connect motor drivers to the control board in a CNC lathe, you start by matching the wires. First, you find the right wires on the motor drivers and the control board. Next, you connect them carefully, following the colors or labels. Once all the wires are connected, you check everything to make sure it’s right. Finally, you power it on and test to see if it works!”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can Be Taken If A Cnc Retrofitted Lathe Experiences Wiring Malfunctions Or Communication Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your CNC retrofitted lathe has wiring problems, first check all the wires. Make sure they’re connected tightly and not damaged. Next, look at the control box for any loose connections. If it’s a communication issue, restart the machine and computer. If the problems keep happening, ask someone with more experience for help.”}}]}