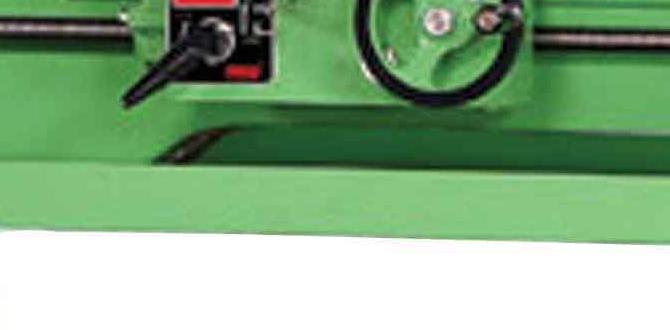

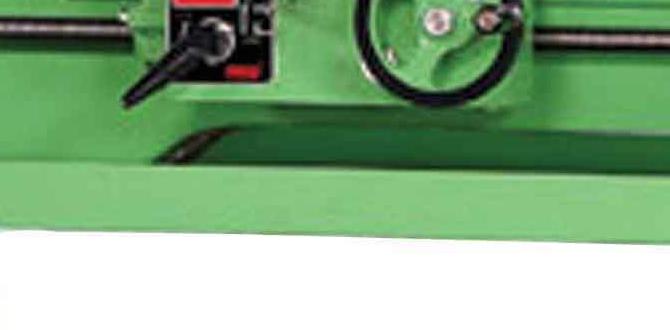

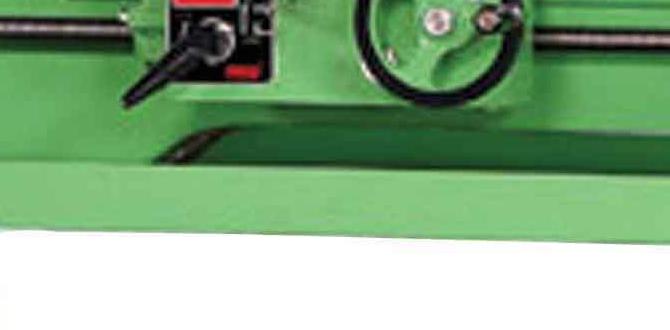

Have you ever wondered how a simple piece of metal can be shaped into something amazing? A lathe does just that! It’s a machine that spins metal while a cutting tool removes material. But what makes a lathe work well? The answer lies in its wiring and the metal lathe compound rest.

Imagine trying to carve a beautiful sculpture from a block of stone. The tool you choose can make all the difference. Similarly, the lathe’s wiring connects everything together. This connection powers the machine and controls its movements.

Many people don’t realize how essential the compound rest is. This part helps you create precise cuts and angles. It allows you to adjust your work easily. Without it, working with a lathe would be much harder.

In this article, we will explore how lathe wiring and the metal lathe compound rest work hand in hand. You’ll discover tips and tricks to improve your metalworking skills. Get ready to dive into the fascinating world of lathes!

Lathe Wiring: Understanding Metal Lathe Compound Rest Setup Introduction Setting Up Your Metal Lathe Is Crucial For Achieving Precision In Your Projects. One Of The Essential Components Of A Lathe Is The Compound Rest, Which Plays A Vital Role In The Accuracy Of Your Cuts And The Overall Operation Of The Machine. In This Article, We Will Explore The Lathe Wiring Basics And How To Effectively Use The Metal Lathe Compound Rest. What Is Lathe Wiring? Lathe Wiring Refers To The Electrical Connections And Configurations That Power Your Lathe Machine. Proper Wiring Ensures That Your Lathe Operates Efficiently And Safely. Understanding How To Wire Your Lathe Correctly Is Essential For Any Machinist, As It Can Affect Performance And Safety. Importance Of The Metal Lathe Compound Rest The Compound Rest Is An Integral Part Of The Metal Lathe That Allows You To Make Angled Cuts And Adjustments. Its Functionality Directly Impacts The Quality Of Your Work. Here Are Several Reasons Why The Compound Rest Is Important: 1. **Precision Cuts**: The Ability To Make Precise Adjustments Leads To Better Finishes And Tighter Tolerances In Your Machining Tasks. 2. **Versatility**: With The Compound Rest, You Can Set Up Various Cutting Angles, Which Enhances Your Ability To Tackle Complex Projects. 3. **Stability**: A Well-Adjusted Compound Rest Provides A Stable Platform For The Cutting Tool, Reducing Vibration And Ensuring Smoother Operation. Wiring Setup For Your Metal Lathe Before Diving Into Using Your Metal Lathe And Its Compound Rest, It’S Crucial To Ensure That The Wiring Is Correctly Set Up. Follow These Steps: 1. **Disconnect Power**: Always Ensure Your Lathe Is Unplugged Before Working On Any Wiring. 2. **Identify Wiring Requirements**: Refer To Your Lathe’S Manual To Understand The Voltage And Wiring Configurations Needed. 3. **Check Wiring Connections**: Inspect All Connections For Damage Or Wear, And Ensure They Are Securely Fitted. 4. **Grounding**: Properly Ground The Lathe To Prevent Electrical Shocks And Ensure Safety During Operation. Using The Compound Rest Once Your Lathe Is Wired And Ready For Operation, You Can Start Using The Compound Rest: 1. **Adjusting The Angle**: Loosen The Locking Mechanism On The Compound Rest, Set Your Desired Angle, And Then Re-Lock It Into Place. 2. **Positioning The Tool**: Position Your Cutting Tool On The Tool Post And Make Any Necessary Fine Adjustments For Better Accuracy. 3. **Testing**: Before Starting Your Machining Process, Perform A Dry Run To Ensure Everything Is Set Correctly Without Cutting Material. Conclusion Lathe Wiring And Understanding How To Use The Metal Lathe Compound Rest Are Fundamental Skills For Any Machinist Looking To Enhance Their Work Quality And Efficiency. With Proper Setup And Adjustments, You Can Ensure That Your Lathe Operates Smoothly And Provides Excellent Results For Your Projects.

Lathe Wiring: Understanding the Metal Lathe Compound Rest

When working with a metal lathe, the compound rest is key to precise cutting. It allows for quick adjustments and better control. Have you ever wondered how the wiring connects all parts? Proper wiring ensures smooth operation and safety while you work. To avoid mishaps, knowing the layout and connections is crucial. A fun fact: the compound rest can spin at different angles, enhancing creativity in your projects! Understanding this can make your lathe experience much more enjoyable.What is a Metal Lathe Compound Rest?

Definition and purpose of a compound rest in metal lathes.. Importance of compound rest in precision machining processes..A compound rest is an important part of a metal lathe. It holds the cutting tool at a specific angle. This helps create precise shapes and sizes on the metal piece being worked on. The compound rest can move in different directions. This movement allows for more complex cuts. Without it, metalworking would be less accurate. The compound rest is essential for detailed projects and can improve the quality of the finished product.

What is a compound rest used for?

The compound rest is used for precise cutting and shaping in metal lathes. It helps create angles and contours that are hard to do without it.

Benefits include:

- Improved accuracy in metal shaping.

- Flexibility in tool positioning.

- Ability to perform complex cuts easily.

Components of Lathe Wiring

Detailed description of key wiring components (e.g., switches, relays, motors).. Importance of each component in the lathe operation..Lathe wiring involves several key components that work together to make the magic happen. First up, we have switches! These little heroes control power. Then come relays, which act like traffic cops for electrical flow. They ensure everything runs smoothly and safely. Don’t forget the motors; they provide the power needed for movement. Without these parts, your lathe might just sit there looking pretty—a fancy paperweight! Remember, each piece is vital for keeping operations safe and efficient.

| Component | Function |

|---|---|

| Switches | Control the power supply |

| Relays | Manage electrical flow |

| Motors | Provide movement power |

Wiring the Compound Rest: Step-by-step Guide

Tools required for wiring the compound rest.. Detailed wiring procedures for connecting the compound rest to the lathe..Ready to wire your compound rest? You’ll need some tools to get started. Grab a screwdriver, wire strippers, and a multimeter. These handy items will be your best friends. Once you have them, follow these steps to connect the compound rest to the lathe:

| Step | Description |

|---|---|

| 1 | Turn off the power. No one wants to be shocked! |

| 2 | Strip the wires carefully. Think of it as giving them a haircut! |

| 3 | Connect the wires to the lathe. Tube steak, meet hot dog! |

| 4 | Secure everything tightly. You want it safe and sound. |

| 5 | Power it on and check your work. Cross your fingers and hope it’s magic! |

By following these steps, you’ll have your compound rest wired up like a pro in no time. Now, go ahead and make those metal pieces dance! And remember, a well-wired lathe might not win awards, but it sure will win smiles!

Common Wiring Issues and Troubleshooting

Identification of common wiring problems in metal lathes.. Troubleshooting tips for resolving wiring issues effectively..Wiring issues in metal lathes can be as tricky as finding a needle in a haystack. Common problems include frayed wires, loose connections, and faulty switches. Each of these can stop your lathe in its tracks, and that’s no fun on a busy workday! To troubleshoot effectively, start by checking for loose wires. Make sure everything is connected tightly, like a group of friends at a concert.

If you spot a broken wire, strip it down and reconnect it. If that fails, you might want to test your switches because a faulty switch can be like a stubborn door that just won’t budge. Remember, supervising your wiring is vital for smooth operations!

| Problem | Solution |

|---|---|

| Frayed wires | Replace or reconnect |

| Loose connections | Tighten all connections |

| Faulty switches | Test and replace |

So, put on your detective hat and start troubleshooting! Remember, safety first: always unplug your lathe before diving in.

Safety Precautions When Wiring a Metal Lathe

Essential safety measures to take before starting lathe wiring.. Personal protective equipment (PPE) recommendations..Before diving into the world of lathe wiring, it’s important to take a few safety steps. First, wear your personal protective equipment (PPE) like goggles to shield your eyes and gloves to protect your hands. It’s hard to have fun with wires when you’re nursing a cut, right? Always work in a clean, dry area to avoid slipping on stray tools or cables. Also, remember, if you aren’t sure what to do, ask for help. Better safe than sorry, and someone yelling “Watch out!” is never a good sign!

| PPE Recommendations | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Gloves | Prevents cuts and scrapes |

| Steel-Toed Boots | Shields feet from heavy objects |

Maintenance Tips for Lathe Wiring and Compound Rest

Routine maintenance practices to ensure longlasting wiring connections.. Signs that indicate the need for maintenance or rewiring..Keeping your lathe in tip-top shape is a breeze with some regular check-ups. Check for frayed wires and loose connections. These are like little warning signs saying, “Help! I need maintenance!” If your machine starts making strange noises or sparks, it’s time to take action. A little care now can save you from a big mess later. Remember, a happy lathe means happy projects!

| Signs You Need Maintenance | Action to Take |

|---|---|

| Frayed Wires | Inspect and replace. |

| Loose Connections | Tighten and secure. |

| Strange Noises | Check for issues. |

| Sparking | Seek professional help. |

Conclusion

In conclusion, understanding lathe wiring and the metal lathe’s compound rest is essential for your projects. Proper wiring ensures safety and efficiency, while the compound rest helps control movements accurately. Remember to study diagrams and guides to improve your skills. So, gather your materials and start experimenting! You can also explore more resources online to deepen your knowledge.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Wiring And The Compound Rest Of A Metal Lathe:Sure! A lathe is a machine that helps us shape metal. The compound rest lets us move the tool in different directions. This helps us make accurate cuts. When we wire a lathe, we connect it to power so it can run. Always be careful with electricity and ask for help if needed!

Sure! Please share the question you’d like me to answer, and I’ll respond in simple terms.

What Are The Essential Electrical Components Required For Wiring A Metal Lathe, And How Do They Interact With The Lathe’S Motor?To wire a metal lathe, you need a few key parts. First, you need a switch that turns the lathe on and off. Then, you’ll need wires to connect everything. A power supply gives energy to the lathe’s motor. These parts work together so the motor can spin the lathe and help you shape metal.

How Does The Design Of The Compound Rest Affect The Precision And Ease Of Use In A Metal Lathe Operation?The compound rest helps you make small, precise cuts on a metal lathe. Its design lets you move the cutting tool easily. This way, you can set the tool exactly where you want it. If it is built well, you will find it easier to use. This means you can make better parts with less effort.

What Safety Precautions Should Be Taken When Wiring A Metal Lathe To Prevent Electrical Hazards During Operation?To keep safe when wiring a metal lathe, always turn off the power first. Use strong materials to protect the wires. Make sure wires are not frayed or damaged. Ground the lathe to prevent shocks. Keep water away from the area to avoid accidents.

How Can One Troubleshoot Common Electrical Issues That May Arise In A Metal Lathe Setup?To troubleshoot electrical issues with a metal lathe, first check the power source. Make sure the power is on and the plugs are secure. Next, inspect the wires for any damage. If it still doesn’t work, consult the manual for specific problems. You can also ask a grown-up for help.

What Modifications Can Be Made To The Wiring System Of A Metal Lathe To Enhance Functionality Or Efficiency, Especially Concerning The Compound Rest?To make a metal lathe work better, you can change its wiring. First, add a switch for the compound rest. This lets you control it easily. You can also use better wires for faster movements. Finally, connect a light to help you see while you work. These changes can make everything smoother and more efficient.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Wiring And The Compound Rest Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. The compound rest lets us move the tool in different directions. This helps us make accurate cuts. When we wire a lathe, we connect it to power so it can run. Always be careful with electricity and ask for help if needed!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer, and I’ll respond in simple terms.”}},{“@type”: “Question”,”name”: “What Are The Essential Electrical Components Required For Wiring A Metal Lathe, And How Do They Interact With The Lathe’S Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a few key parts. First, you need a switch that turns the lathe on and off. Then, you’ll need wires to connect everything. A power supply gives energy to the lathe’s motor. These parts work together so the motor can spin the lathe and help you shape metal.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Compound Rest Affect The Precision And Ease Of Use In A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest helps you make small, precise cuts on a metal lathe. Its design lets you move the cutting tool easily. This way, you can set the tool exactly where you want it. If it is built well, you will find it easier to use. This means you can make better parts with less effort.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe To Prevent Electrical Hazards During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep safe when wiring a metal lathe, always turn off the power first. Use strong materials to protect the wires. Make sure wires are not frayed or damaged. Ground the lathe to prevent shocks. Keep water away from the area to avoid accidents.”}},{“@type”: “Question”,”name”: “How Can One Troubleshoot Common Electrical Issues That May Arise In A Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot electrical issues with a metal lathe, first check the power source. Make sure the power is on and the plugs are secure. Next, inspect the wires for any damage. If it still doesn’t work, consult the manual for specific problems. You can also ask a grown-up for help.”}},{“@type”: “Question”,”name”: “What Modifications Can Be Made To The Wiring System Of A Metal Lathe To Enhance Functionality Or Efficiency, Especially Concerning The Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work better, you can change its wiring. First, add a switch for the compound rest. This lets you control it easily. You can also use better wires for faster movements. Finally, connect a light to help you see while you work. These changes can make everything smoother and more efficient.”}}]}