Have you ever wondered how metal lathes work? These amazing machines shape metal into useful parts. But they need power to operate. That’s where lathe wiring comes into play. A control panel connects the lathe to electricity. Understanding how to wire it correctly can seem tricky, but it’s essential for safety and performance.

Imagine trying to make a perfect part, only to face power issues. That’s frustrating! A good control panel helps you manage speed and direction easily. It can make your metal lathe more fun to use and improve your projects. In this article, we will break down lathe wiring and the control panel into simple steps.

Did you know that a well-wired lathe can last longer and run smoother? Proper wiring means better results. Join us as we explore how to set up your metal lathe’s control panel properly. You’ll be ready to create amazing projects in no time!

Lathe Wiring: Metal Lathe Control Panel Guide For Success

Understanding Lathe Wiring and Control Panels

Lathe wiring connects the machine parts to power and control systems. A well-functioning metal lathe control panel manages speed and direction. Did you know that a simple wiring mistake can cause major problems? Electric currents flow through wires, directing the lathe’s movements. Learning about this setup helps users prevent errors and improve safety. Proper wiring ensures your lathe runs smoothly, making projects easier and more fun!Understanding Lathe Wiring Basics

Explanation of electrical components in a metal lathe. Importance of proper wiring for safety and functionality.Knowing the basics of lathe wiring is important for everyone using a metal lathe. A metal lathe has several electrical parts, like the motor and switches. Each part plays a role in making the lathe work safely and well. Proper wiring helps prevent accidents and keeps the machine functional.

- Power supply: It provides energy to the lathe.

- Motor: This part rotates the workpiece.

- Control panel: It helps you operate the lathe.

- Wires: They connect everything together.

Good wiring means safety and efficiency. It keeps your lathe running smoothly. Remember, safety first!

What are the key components of a metal lathe’s electrical system?

The key components are the motor, control panel, power supply, and wiring. Each part is vital for the lathe to function correctly and safely.

Wiring Schematics for Metal Lathes

Detailed diagrams of typical wiring setups. Variations based on different lathe models.To understand metal lathe wiring, clear diagrams are helpful. Each model may have unique setups. Here are key points to keep in mind:

- Diagrams show where wires connect.

- Each model uses different colors for wires.

- Follow the manual for your specific lathe.

- Common parts include motors and switches.

Having a good wiring schematic can make your work easier and safer.

What are wiring schematics for metal lathes?

Wiring schematics show how to connect wires in metal lathes. They help ensure everything works correctly and safely.

Step-by-Step Guide to Wiring a Metal Lathe Control Panel

Instructions on how to wire each component. Common pitfalls to avoid during installation.Wiring a metal lathe control panel can be simple if you follow the right steps. Start by connecting the main power supply to the control box. Then, attach wires for the motor and switches. Remember to be careful! Avoid mixing up cables, as this can cause problems. Here are some tips:

- Label each wire clearly.

- Use the correct gauge wire for safety.

- Double-check connections before powering on.

Take your time. Making mistakes can lead to costly repairs. Each step matters!

What should I check before finishing the wiring?

Check that all connections are tight. Ensure you have followed the diagram correctly. Finally, double-check that no wires are touching the metal casing, which can cause shorts.

Safety Tips for Lathe Wiring

Guidelines for ensuring electrical safety. Recommendations for protective equipment and procedures.Working with a lathe can be fun, but safety is super important. Always disconnect the power before starting any wiring. Use rubber gloves to protect your hands. If you’re feeling a bit like a superhero, wear safety glasses too! They keep flying bits away from your eyes. It’s wise to use insulated tools; they can save a big shock. Double-check your connections to avoid surprises—no one wants a mini-firework show while working! Here’s a little table to remember:

| Tip | Why |

|---|---|

| Disconnect power | Prevents accidents |

| Wear gloves | Protect hands from shock |

| Use safety glasses | Keeps eyes safe |

| Use insulated tools | Reduces shock risk |

Stay safe and keep your workspace tidy. No one wants a messy disaster! Plus, your future self will thank you when you can keep spinning things safely.

Troubleshooting Common Wiring Issues

Identifying symptoms of wiring problems. Solutions for common electrical failures in metal lathes.Wiring problems can make your metal lathe stop working. Here are some common signs of issues:

- Machine won’t start.

- Lights flicker or won’t turn on.

- Strange sounds when running.

For fixing these issues, try these solutions:

- Check all connections; they might be loose.

- Look for damaged wires that need replacing.

- Inspect fuses to see if they are burnt out.

Troubleshooting now can save time later!

What are some common symptoms of wiring issues?

The common symptoms include the machine not starting, flickering lights, and unusual noises when in use.What solutions exist for electrical failures in metal lathes?

Solutions include checking connections, replacing damaged wires, and inspecting fuses for burnouts.Enhancing Functionality with Upgrades

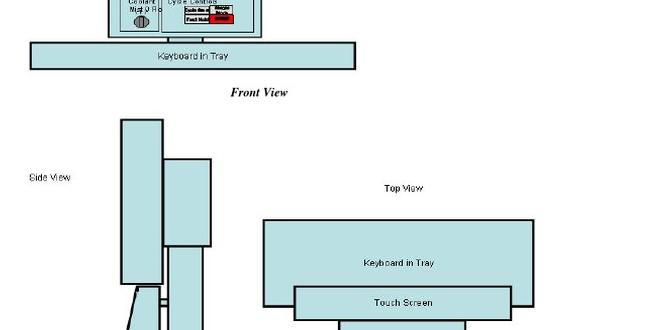

Discuss modern upgrades for control panels. Benefits of integrating advanced features (e.g., digital displays, programmable controls).Upgrading your control panel can bring new life to your metal lathe. Modern features can transform how you work. For instance, digital displays help you see measurements clearly. Programmable controls allow for quick changes, making work easier. Here are some great benefits of upgrades:

- Improved accuracy in projects

- Faster setup times

- Enhanced user experience

- Increased efficiency in operations

These upgrades make your tasks simpler and more fun. Embracing new technology can change your metalworking game.

What are the benefits of modern upgrades for lathe control panels?

Modern upgrades like digital displays and programmable controls enhance accuracy, speed up tasks, and improve the overall user experience. They make operations smoother and faster, which is great for any metalworker.

Conclusion

In conclusion, understanding your lathe’s wiring and control panel is crucial for safe and efficient operation. You can enhance your skills by learning how different controls work. Don’t hesitate to explore manuals or guides online. With practice, you’ll feel more confident using your metal lathe. Keep experimenting and have fun with your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Control Panels:Lathe wiring helps connect the parts of a lathe machine so it can work properly. A metal lathe control panel is where you can control the machine. It has buttons and switches to turn it on and off. You need to be careful when working with wiring. Always ask for help if you’re not sure what to do!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Components Of A Metal Lathe Control Panel And How Are They Wired Together?A metal lathe control panel has a few important parts. First, there is a power switch to turn the machine on and off. Then, there are knobs or buttons to control speed and direction. You also find a display screen to show settings and information. All these parts connect with wires that send signals, helping the lathe work correctly.

How Do You Safely Wire A Variable Frequency Drive (Vfd) To Control The Speed Of A Metal Lathe?To safely wire a variable frequency drive (VFD) to control a metal lathe, first turn off the power. Next, connect the VFD to the lathe’s motor using the right wires. You need to connect three wires: one for power, one for direction, and one for speed. Make sure all connections are tight and secure. Finally, double-check everything before turning the power back on to test it.

What Types Of Electrical Wiring Should Be Used For A Metal Lathe Control Panel To Ensure Proper Functionality And Safety?For a metal lathe control panel, you should use wires that are thick and can handle a lot of power. Look for wires that are rated for high voltage, like 12 or 14 AWG (American Wire Gauge) wire. It’s also important to use wires that are insulated to keep us safe from shocks. Make sure the wires are protected from wear and tear to last a long time. Always double-check your connections to make sure everything works well and is safe.

How Can You Troubleshoot Electrical Issues Within A Metal Lathe Control Panel?To troubleshoot electrical issues in a metal lathe’s control panel, you start by checking the power. Make sure it’s plugged in and the switch is on. Then, look for loose wires inside the panel. If you see any, gently tight or reconnect them. Finally, if nothing works, ask an adult for help.

What Safety Precautions Should Be Taken When Working On The Wiring And Control Panel Of A Metal Lathe?When working on the wiring and control panel of a metal lathe, you should always unplug the machine first. This keeps you safe from electric shocks. Wear safety goggles to protect your eyes from dust or sparks. Keep your workspace clean and dry to avoid slips and falls. Finally, make sure to follow all instructions so you can stay safe while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe wiring helps connect the parts of a lathe machine so it can work properly. A metal lathe control panel is where you can control the machine. It has buttons and switches to turn it on and off. You need to be careful when working with wiring. Always ask for help if you’re not sure what to do!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe Control Panel And How Are They Wired Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel has a few important parts. First, there is a power switch to turn the machine on and off. Then, there are knobs or buttons to control speed and direction. You also find a display screen to show settings and information. All these parts connect with wires that send signals, helping the lathe work correctly.”}},{“@type”: “Question”,”name”: “How Do You Safely Wire A Variable Frequency Drive (Vfd) To Control The Speed Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely wire a variable frequency drive (VFD) to control a metal lathe, first turn off the power. Next, connect the VFD to the lathe’s motor using the right wires. You need to connect three wires: one for power, one for direction, and one for speed. Make sure all connections are tight and secure. Finally, double-check everything before turning the power back on to test it.”}},{“@type”: “Question”,”name”: “What Types Of Electrical Wiring Should Be Used For A Metal Lathe Control Panel To Ensure Proper Functionality And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe control panel, you should use wires that are thick and can handle a lot of power. Look for wires that are rated for high voltage, like 12 or 14 AWG (American Wire Gauge) wire. It’s also important to use wires that are insulated to keep us safe from shocks. Make sure the wires are protected from wear and tear to last a long time. Always double-check your connections to make sure everything works well and is safe.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Electrical Issues Within A Metal Lathe Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot electrical issues in a metal lathe’s control panel, you start by checking the power. Make sure it’s plugged in and the switch is on. Then, look for loose wires inside the panel. If you see any, gently tight or reconnect them. Finally, if nothing works, ask an adult for help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working On The Wiring And Control Panel Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working on the wiring and control panel of a metal lathe, you should always unplug the machine first. This keeps you safe from electric shocks. Wear safety goggles to protect your eyes from dust or sparks. Keep your workspace clean and dry to avoid slips and falls. Finally, make sure to follow all instructions so you can stay safe while working.”}}]}