Have you ever watched a metal lathe in action? It’s fascinating! A lathe can shape metal into all sorts of cool objects. But have you ever thought about how the lathe wiring works? Knowing about the metal lathe drive system is pretty important for anyone who wants to understand lathes better.

Imagine you’re building a toy car from metal. You need precise cuts and shapes. That’s where the lathe comes in. It spins the metal while a tool cuts it exactly right. But without the right wiring, the entire process could go wrong.

In this article, we will explore the ins and outs of lathe wiring. You’ll learn how these systems work. You’ll discover why they are crucial for running a metal lathe safely and effectively. Plus, we’ll share tips for setting up your own lathe wiring. Ready to dive in?

Lathe Wiring: Understanding The Metal Lathe Drive System

Lathe Wiring: Understanding Your Metal Lathe Drive System

When working with a metal lathe, the drive system is essential. It powers the machine to cut and shape metal precisely. Knowing how to wire this system correctly is vital. Mistakes can lead to poor performance or accidents. A fun fact is that old lathes used belts, while modern ones often use electrical motors. Learning about lathe wiring can help you fix or upgrade your machine. Can you imagine creating a perfect piece of art from metal? Aim to master your lathe!Different Types of Metal Lathe Wiring Configurations

Comparison of basic and advanced wiring setups. Benefits and drawbacks of each configuration.When it comes to wiring a metal lathe, there are basic and advanced setups. Basic wiring is like your trusty old bike—it gets the job done without any fancy tricks. It’s simple and easy to fix, perfect for beginners. However, it may not handle heavy jobs well. On the flip side, advanced wiring is like a shiny sports car—it zips through tasks smoothly and offers more features. But with that flair comes complexity and higher repair costs.

| Configuration | Benefits | Drawbacks |

|---|---|---|

| Basic Wiring | Simple and easy to maintain | Limited in heavy-duty tasks |

| Advanced Wiring | Handles complex tasks efficiently | More complicated and expensive to repair |

In choosing between the two, think of your needs and skills. You wouldn’t want a sports car if you can barely ride a bike, right? Remember, it’s all about finding what works best for you!

Wiring a Metal Lathe: Step-by-Step Guide

Detailed instructions for wiring a basic lathe system. Safety precautions to take during the wiring process.Wiring a metal lathe requires careful steps and safety. Start by gathering tools like wire strippers and connectors. It’s important to wear safety goggles and gloves. Double-check the power supply before beginning. Connect the wires as follows:

- Identify the motor connections.

- Connect the power wires to the control panel.

- Ensure all connections are secure.

- Test the system before use.

Keep your workspace clean and free of obstacles. This will help prevent accidents while wiring.

What are the safety precautions for wiring a lathe?

Some safety precautions include:

- Wear safety goggles to protect your eyes.

- Use insulated tools to avoid electric shock.

- Work in a dry area to reduce risks.

Maintenance Tips for Lathe Wiring Systems

Best practices for ensuring longevity and optimal performance. Regular checks and preventive measures.To keep your lathe wiring system in great shape, follow these tips. Check connections regularly to spot any signs of wear. Clean dust and debris from wires to avoid problems. Make sure all parts stay lubricated.

- Inspect wires for frays or cuts.

- Test the connection tightness monthly.

- Replace damaged parts quickly.

- Run your lathe at the proper voltage.

These steps help ensure your lathe runs smoothly and lasts longer!

How often should I check my lathe wiring?

You should check your lathe wiring at least once a month. This keeps everything safe and working well.

Upgrading Your Metal Lathe Drive System

Signs that an upgrade is necessary. Suggestions for new technologies and components to improve efficiency.Is your metal lathe making strange noises? Or maybe it’s slower than a snail on a Sunday stroll? These are signs that it’s time for an upgrade. New technologies like digital displays and brushless motors can improve efficiency. They can make your lathe work like a well-oiled machine. Consider checking out some advanced drive systems that offer better speed control and precision.

| Signs You Need an Upgrade | Suggested Technologies |

|---|---|

| Unusual noises | Digital displays |

| Slow speeds | Brushless motors |

| Frequent breakdowns | Advanced drive systems |

Upgrading not only helps you work faster, but it can also make your lathe feel young again. Think of it like a spa day for your machine—treat it right, and it will treat you right back!

Resources for Further Learning

Recommended books, online courses, and tutorials. Community forums and expert groups for ongoing support.Ready to dive deeper into the wonders of lathe wiring? Start by checking out some recommended books. They can really turn you into a pro! Online courses and tutorials are a great choice too. They’re like having a teacher in your pocket, minus the awkward eye contact. Don’t forget to join community forums and expert groups. These are like the cool kids’ table, where you can ask questions and share ideas. Let’s make learning fun!

| Resource Type | Examples |

|---|---|

| Books | The Lathe Book, Metalworking Sink or Swim |

| Online Courses | Coursera, Udemy |

| Forums | Practical Machinist, CNCZone |

Conclusion

In summary, understanding lathe wiring is essential for operating a metal lathe drive system safely. You control speed and power through proper connections. Always follow guidelines for wiring to ensure smooth operation. If you want to dive deeper, check out resources or tutorials online. With practice, you’ll become skilled at using your lathe effectively and safely!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Drive Systems:Sure! A lathe is a machine that helps us shape metal or wood. It spins the material while a cutting tool shapes it. The wiring in a lathe connects the power source to the motor. This helps the lathe move and cut properly. Understanding how it works lets us use lathes safely and effectively.

Sure! Please provide the question you would like me to answer.

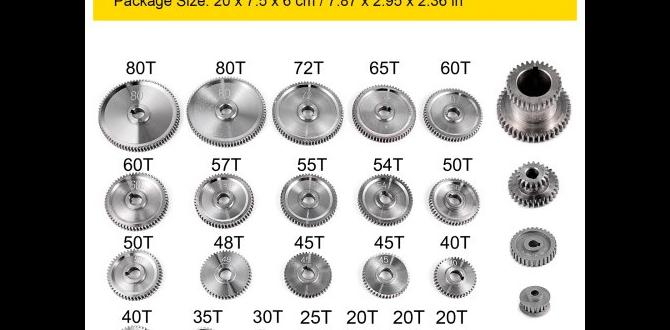

What Are The Key Components Of A Metal Lathe’S Drive System, And How Do They Interact With The Wiring?A metal lathe’s drive system has a few key parts. First, there’s the motor, which makes everything move. Next, we have belts that connect the motor to the spinning parts. These belts help transfer the power to the machine. Finally, the wiring sends electricity to the motor, allowing it to work. All these parts work together to help create shapes from metal.

How Do You Troubleshoot Electrical Issues In A Metal Lathe’S Drive System, Particularly Concerning The Motor And Control Circuitry?To troubleshoot electrical issues in a metal lathe’s drive system, we first check the power supply. Make sure it’s plugged in and turned on. Next, look at the motor connections for any loose or damaged wires. If everything seems okay, you can test the control panel to see if it works properly. If you’re still having problems, it might help to ask an adult for assistance.

What Types Of Power Supplies Are Commonly Used For Metal Lathe Drive Systems, And What Are Their Advantages And Disadvantages?Metal lathes usually use two types of power supplies: electric motors and hydraulic systems. Electric motors are popular because they are easy to use and keep. They can work fast, but if they overheat, they might stop. Hydraulic systems use oil to move and are strong, but they can be messy and cost more to fix. Each type has its good and bad points!

How Can You Safely Wire A Variable Frequency Drive (Vfd) For A Metal Lathe To Control Spindle Speed And Torque?To safely wire a Variable Frequency Drive (VFD) for a metal lathe, you start by turning off the power. Next, connect the VFD to the lathe’s motor using the correct wires. You also need to connect the VFD to your power source, making sure the voltage matches. Finally, follow the VFD’s instructions carefully to set the right speed and torque. Always double-check your connections before turning the power back on!

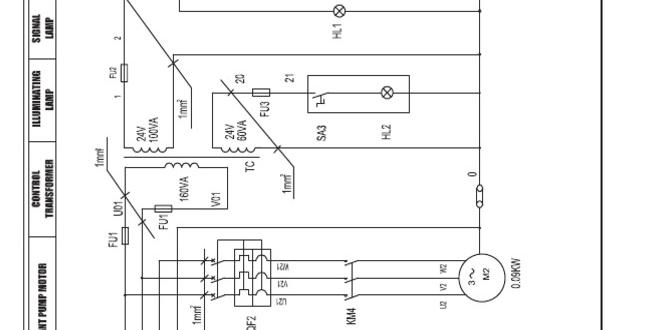

What Wiring Diagrams And Safety Standards Should Be Followed When Installing Or Repairing A Metal Lathe’S Drive System?When installing or fixing a metal lathe’s drive system, follow proper wiring diagrams. These diagrams show how to connect the wires safely. Always use safety standards like wearing gloves and goggles. Make sure to turn off the power before you start. This keeps you safe while you work on the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal or wood. It spins the material while a cutting tool shapes it. The wiring in a lathe connects the power source to the motor. This helps the lathe move and cut properly. Understanding how it works lets us use lathes safely and effectively.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe’S Drive System, And How Do They Interact With The Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe’s drive system has a few key parts. First, there’s the motor, which makes everything move. Next, we have belts that connect the motor to the spinning parts. These belts help transfer the power to the machine. Finally, the wiring sends electricity to the motor, allowing it to work. All these parts work together to help create shapes from metal.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Electrical Issues In A Metal Lathe’S Drive System, Particularly Concerning The Motor And Control Circuitry?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot electrical issues in a metal lathe’s drive system, we first check the power supply. Make sure it’s plugged in and turned on. Next, look at the motor connections for any loose or damaged wires. If everything seems okay, you can test the control panel to see if it works properly. If you’re still having problems, it might help to ask an adult for assistance.”}},{“@type”: “Question”,”name”: “What Types Of Power Supplies Are Commonly Used For Metal Lathe Drive Systems, And What Are Their Advantages And Disadvantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes usually use two types of power supplies: electric motors and hydraulic systems. Electric motors are popular because they are easy to use and keep. They can work fast, but if they overheat, they might stop. Hydraulic systems use oil to move and are strong, but they can be messy and cost more to fix. Each type has its good and bad points!”}},{“@type”: “Question”,”name”: “How Can You Safely Wire A Variable Frequency Drive (Vfd) For A Metal Lathe To Control Spindle Speed And Torque?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely wire a Variable Frequency Drive (VFD) for a metal lathe, you start by turning off the power. Next, connect the VFD to the lathe’s motor using the correct wires. You also need to connect the VFD to your power source, making sure the voltage matches. Finally, follow the VFD’s instructions carefully to set the right speed and torque. Always double-check your connections before turning the power back on!”}},{“@type”: “Question”,”name”: “What Wiring Diagrams And Safety Standards Should Be Followed When Installing Or Repairing A Metal Lathe’S Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When installing or fixing a metal lathe’s drive system, follow proper wiring diagrams. These diagrams show how to connect the wires safely. Always use safety standards like wearing gloves and goggles. Make sure to turn off the power before you start. This keeps you safe while you work on the lathe.”}}]}