Have you ever wondered how metal lathes work? These machines are fascinating! At the heart of a metal lathe, you will find a complex gear train. This gear train helps control the movement of the lathe. It allows us to create precise shapes and parts from solid metal.

Imagine building a toy car. You need different gears to make the wheels turn smoothly. Just like that, the gear train in a lathe helps to shape metal. It connects the power source to the spinning parts. Without it, making accurate cuts would be almost impossible.

But what about the wiring? The wiring connects the lathe to its power supply. It ensures that everything runs properly. If the wires are not connected correctly, the lathe won’t work at all! How can you ensure your metal lathe is wired correctly? That is what we will explore.

Get ready to dive into the world of lathe wiring and gear trains! You will learn the basics, find tips, and discover how to keep your metal lathe running smoothly. It’s time to spark your curiosity and explore!

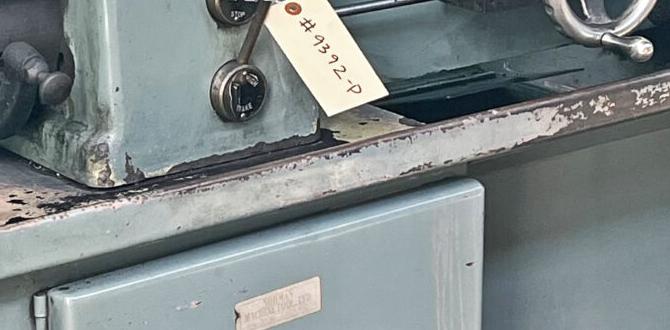

Lathe Wiring: Understanding Metal Lathe Gear Train Basics

Lathe Wiring Metal Lathe Gear Train

Understanding lathe wiring and gear trains is crucial for any metal lathe user. A metal lathe works wonders in shaping materials, but its machinery needs proper wiring to function well. Have you ever wondered how a lathe’s gear train operates? It connects the machine’s motor to the spindle, making all the magic happen. Correct wiring ensures reliable performance and safety. Learning about these components can help you tackle projects smoothly and efficiently, turning your ideas into reality.Essential Tools for Lathe Wiring

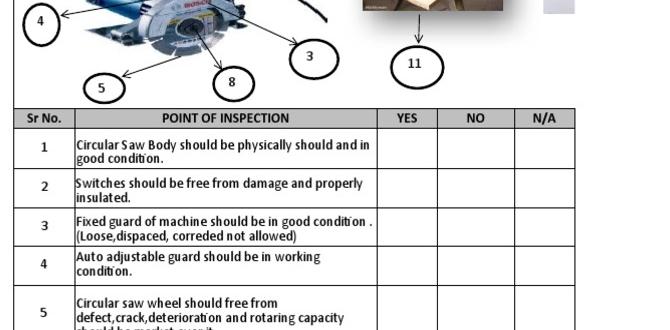

List of tools needed for electrical work on lathes. Safety equipment and precautions to consider.Working with lathes can be fun, but don’t forget your tools! You’ll need some essential items for a safe and successful time. Here’s a quick list:

| Tool | Purpose |

|---|---|

| Insulated Screwdriver | To safely work with electrical connections |

| Wire Stripper | For removing insulation from wires |

| Multimeter | To measure voltage and ensure safety |

| Safety Goggles | Protect your eyes from flying sparks |

Always remember safety first! Equip yourself with proper gear and never tackle wiring alone. It’s easier to avoid shock than to explain it to your friends. Happy lathing!

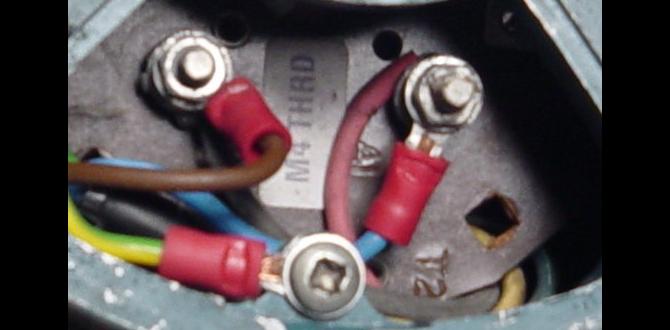

Step-by-Step Guide to Wiring Your Lathe

Detailed wiring diagram explanation. Connection points and their significance.Wiring your lathe requires careful steps. A clear wiring diagram helps you connect the parts correctly. Each connection point matters. Wrong connections can cause issues. Take time to understand each part and its purpose. Here’s a simple breakdown:

- Power supply: It provides energy to the lathe.

- Main switch: Controls the power to the machine.

- Motor connections: Moves the lathe for shaping metal.

- Control panel: Lets you adjust settings easily.

Using the right wiring can make all the difference. Be patient and follow your plan!

What should I know about the wiring diagram?

A wiring diagram shows how the wires connect. It’s like a map for your lathe. Pay attention to each line and label. This will help you avoid mistakes!

Common Wiring Issues and Troubleshooting

Identifying typical wiring problems in lathes. Solutions for common issues encountered.Wiring problems in lathes can make you feel like you’ve entered a maze. Common issues include frayed wires, loose connections, or burnt-out fuses. These can lead to unexpected stops or strange noises, like a grumpy old man complaining! Troubleshooting starts with checking connections. If you see something loose, tighten it up. If a wire looks like it had a run-in with a pair of teeth, it’s time to replace it. Here’s a handy table outlining the problems and their fixes:

| Issue | Solution |

|---|---|

| Frayed wires | Replace the wire |

| Loose connections | Tighten the connections |

| Burnt-out fuses | Change the fuse |

Being aware of these issues lets you keep your lathe running smoothly. Remember, a little maintenance goes a long way, like a good cup of coffee on a Monday morning!

Designing a Custom Gear Train for Your Lathe

Factors to consider when designing a gear train. Compatibility with existing lathe components.Creating a special gear train for your lathe can be a fun, yet puzzling puzzle! First, think about the size and power of your lathe. The gears must fit together nicely with your current setup, sort of like trying to find the right key for a lock. Be sure to check your existing lathe parts to avoid any surprises! Also, talk to the experts when needed. After all, even superheroes need sidekicks sometimes!

| Factor | Importance |

|---|---|

| Size of Gears | Must fit current setup |

| Material | Makes gears long-lasting |

| Power Compatibility | Ensures smooth operation |

| Expert Consultation | Prevents mistakes and saves time |

Keep these fun factors in mind, and your custom gear train will have you lathe-ing like a pro in no time!

Adjustments and Maintenance of Gear Trains

Regular maintenance tips for optimal gear train performance. How to adjust gear ratios for specific machining tasks.Taking care of your gear train is key to keeping everything running smoothly. Regular oiling can help prevent rust and keep gears happy. A good rule of thumb? Check those gears every few months! When using your lathe, you might need to adjust the gear ratios. This helps tailor the machine to your needs. Think of it like picking the right gear for a bike—choose wisely to avoid pedaling like you’re stuck in mud!

| Maintenance Tips | Adjustment Methods |

|---|---|

| Oil gears regularly | Shift ratios for tasks |

| Inspect for wear | Test settings before full use |

| Clean debris off gears | Use correct gear pairs |

By following these tips, you can keep your lathe and gear train in tip-top shape. As a famous engineer once said, “A well-oiled machine runs best!” Let’s keep those gears spinning!

Upgrading Your Lathe Gear Train System

Signs your gear train may need an upgrade. Options for modernizing gear train components.Look for signs that your gear train system may need an upgrade. If you hear strange noises or notice uneven cuts, it’s time to act. Upgrade your gears for smoother performance. You can consider options like:

- Changing old gears

- Adding modern drives

- Improving lubrication methods

Keeping your gear train updated helps your lathe work better. It saves time and improves your projects.

What are signs that my gear train needs an upgrade?

Signs include unusual sounds or vibrations while operating. **These can mean gears are worn out or misaligned.** Regular checks help find problems early.

Comparative Analysis of Lathe Wiring and Gear Train Setup

How wiring and gear train efficiency impact lathe performance. Case studies of successful setups versus common mistakes.Wiring and gear train setups play a big role in how well a lathe works. Think of them as the espresso shots that wake up your machine! If connections are strong and the gear train is set up right, you get smooth performance and less wear and tear. But mess up these details, and your lathe could sound like a cat caught in a blender. Studies show that proper setups boost efficiency by up to 30%, saving time and frustration. Here’s a quick view of what works and what doesn’t:

| Setup Type | Efficiency | Common Mistakes |

|---|---|---|

| Successful Wiring | High | Poor insulation |

| Good Gear Train | Very High | Incorrect gear ratios |

| Poor Setup | Low | Loose connections |

In the end, a little care can make your lathe run like a champ!

Conclusion

In conclusion, understanding lathe wiring and the metal lathe gear train is essential for efficient machining. You now know how gear trains work and their importance in tool performance. Remember, proper wiring ensures safety and accuracy. Try experimenting with your lathe or reading more about gears to deepen your skills. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Specifically Focusing On Metal Lathe Gear Trains:Sure! Here are five questions about lathe wiring and metal lathe gear trains. First, what is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. Next, why do we need gears in a lathe? Gears help change the speed and direction of the spinning material. They make it easier to shape the material properly. What does wiring do in a lathe? Wiring connects parts so the lathe works. It helps power the motor and control the machine. How do we care for lathe gears? We should keep them clean and well-oiled. This way, they will work better and last longer. Finally, are safety rules important when using a lathe? Yes, safety rules keep you safe while using the lathe. Always wear safety glasses and follow directions!

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Is The Purpose Of A Gear Train In A Metal Lathe, And How Does It Affect The Machine’S Performance?A gear train in a metal lathe helps to change the speed and direction of the machine’s parts. It makes the lathe run smoothly and do different tasks. When we adjust the gear train, we can cut metal more easily or make detailed shapes. This helps us get better results in our projects. Overall, the gear train is important for how well the lathe works.

How Do You Wire The Motor For A Metal Lathe With A Gear Train To Ensure Optimal Torque And Speed Control?To wire the motor for a metal lathe, you first connect the motor to a power supply. You should use a switch so you can easily turn it on and off. Next, connect wires to your gear train, which helps control speed and torque. Make sure to follow a wiring diagram specific to your motor so you don’t get mixed up. Finally, test it to see if everything works well together!

What Are The Common Issues Encountered With The Wiring Of The Gear Train In A Metal Lathe, And How Can They Be Troubleshooting?Some common problems with the wiring in a metal lathe’s gear train include loose wires or broken connections. You might notice the machine not working right or stopping suddenly. To fix this, you can check all the wires and tighten any loose ones. If you find broken wires, you should replace them. Always make sure to turn off the machine before checking anything!

How Does The Selection Of Gear Ratios In The Gear Train Impact The Machining Capabilities Of A Metal Lathe?Choosing the right gear ratios in a metal lathe helps control its speed and power. This means you can turn metal faster or slower, depending on what you need to do. If you want precision, you might pick a lower speed. If you need to remove a lot of metal quickly, a higher speed helps. The right gear ratios make your work easier and better!

What Safety Precautions Should Be Taken When Wiring And Operating The Gear Train Of A Metal Lathe?When working with a metal lathe, always wear safety goggles to protect your eyes. Keep loose clothing and hair away from moving parts. Make sure you understand how the machine works before you start. Never touch the gears while the lathe is running. Finally, ask an adult for help if you’re unsure about anything.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Specifically Focusing On Metal Lathe Gear Trains:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe wiring and metal lathe gear trains. First, what is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. Next, why do we need gears in a lathe? Gears help change the speed and direction of the spinning material. They make it easier to shape the material properly. What does wiring do in a lathe? Wiring connects parts so the lathe works. It helps power the motor and control the machine. How do we care for lathe gears? We should keep them clean and well-oiled. This way, they will work better and last longer. Finally, are safety rules important when using a lathe? Yes, safety rules keep you safe while using the lathe. Always wear safety glasses and follow directions!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Gear Train In A Metal Lathe, And How Does It Affect The Machine’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gear train in a metal lathe helps to change the speed and direction of the machine’s parts. It makes the lathe run smoothly and do different tasks. When we adjust the gear train, we can cut metal more easily or make detailed shapes. This helps us get better results in our projects. Overall, the gear train is important for how well the lathe works.”}},{“@type”: “Question”,”name”: “How Do You Wire The Motor For A Metal Lathe With A Gear Train To Ensure Optimal Torque And Speed Control?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire the motor for a metal lathe, you first connect the motor to a power supply. You should use a switch so you can easily turn it on and off. Next, connect wires to your gear train, which helps control speed and torque. Make sure to follow a wiring diagram specific to your motor so you don’t get mixed up. Finally, test it to see if everything works well together!”}},{“@type”: “Question”,”name”: “What Are The Common Issues Encountered With The Wiring Of The Gear Train In A Metal Lathe, And How Can They Be Troubleshooting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common problems with the wiring in a metal lathe’s gear train include loose wires or broken connections. You might notice the machine not working right or stopping suddenly. To fix this, you can check all the wires and tighten any loose ones. If you find broken wires, you should replace them. Always make sure to turn off the machine before checking anything!”}},{“@type”: “Question”,”name”: “How Does The Selection Of Gear Ratios In The Gear Train Impact The Machining Capabilities Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right gear ratios in a metal lathe helps control its speed and power. This means you can turn metal faster or slower, depending on what you need to do. If you want precision, you might pick a lower speed. If you need to remove a lot of metal quickly, a higher speed helps. The right gear ratios make your work easier and better!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring And Operating The Gear Train Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with a metal lathe, always wear safety goggles to protect your eyes. Keep loose clothing and hair away from moving parts. Make sure you understand how the machine works before you start. Never touch the gears while the lathe is running. Finally, ask an adult for help if you’re unsure about anything.”}}]}