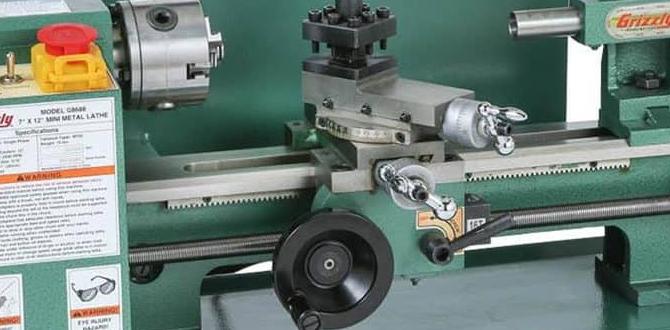

Have you ever wondered how metal lathes work? These amazing machines shape metal into useful parts. The secret often lies in their wiring and pulleys.

Imagine you are in a workshop. The sound of a lathe fills the air. You see how it spins and cuts metal with ease. But have you noticed the pulleys and wires that help it move? They play a key role in its operation.

In this article, we will explore lathe wiring and the different types of metal lathe pulleys. You might be surprised to learn how these parts can make a big difference in performance. Understanding them could even help you fix your own lathe one day.

So, are you ready to dive into the world of lathes? Let’s uncover the mysteries of wiring and pulleys together!

Lathe Wiring: Connecting Your Metal Lathe Pulley System

Lathe Wiring: Metal Lathe Pulley Insights

Understanding lathe wiring, especially concerning metal lathe pulleys, is essential for aspiring machinists. Proper wiring ensures that the pulley system operates smoothly and efficiently. Did you know the right pulley can boost your lathe’s performance? By choosing the correct size and material, you can enhance cutting speed and precision. Knowing how to wire your lathe can save you time and prevent issues. Don’t overlook the importance of a well-functioning pulley in your projects!Understanding Metal Lathe Wiring

Explanation of metal lathe components related to wiring. Importance of proper wiring for metal lathe operation.Wiring a metal lathe isn’t just about connecting wires. It’s like putting together the superheroes of the metalworking world! Each part has a special job. The pulley spins round and round, helping the lathe operate smoothly. Proper wiring ensures all parts work together efficiently. If the wiring is off, the lathe might throw a tantrum instead of cutting metal. Trust me, no one wants a cranky lathe! So, keep those wires neat and tidy for a happy workshop!

| Component | Function |

|---|---|

| Pulley | Transfers power to the spindle |

| Motor | Drives the lathe |

| Switch | Turns the machine on and off |

Safety Precautions When Wiring a Metal Lathe

Necessary safety gear and equipment. Best practices to avoid electrical hazards during installation.Before you start wiring that metal lathe, gear up like a superhero! Wear sturdy gloves, safety glasses, and make sure your hair is tied back. This helps keep you safe from flying bits of metal and avoids electrical shocks. Always work with one hand, like a ninja, to avoid becoming a human lightbulb! Remember to stay dry and use insulated tools. Want to be extra safe? Check the equipment’s manual, because even machines have rules!

| Safety Gear | Description |

|---|---|

| Gloves | Protects your hands from sharp metal pieces. |

| Safety Glasses | Shields your eyes from metal splinters. |

| Insulated Tools | Reduces the risk of electrical shock. |

Always turn off the power before starting. Double-check connections before plugging in. Following these steps can help avoid electrical hazards. Remember, safety first means you get to keep your fingers!

Step-by-Step Process to Wire a Metal Lathe

Detailed wiring instructions for different types of metal lathes. Common wiring configurations for pulley systems.Wiring a metal lathe can seem tricky, but let’s break it down into simple steps. First, identify the type of lathe you have; some might be like that friend who always wants to change plans! Next, check the wiring configuration for your pulley system. It’s all about the right connections so that it doesn’t turn into a spaghetti monster. Here’s a quick look at common wiring setups:

| Type of Lathe | Wiring Configuration |

|---|---|

| Single-Phase Lathe | Connect to a 120/240V outlet |

| Three-Phase Lathe | Connect using a phase converter |

Once wired, check everything twice. Remember, wiring can zap you faster than a squirrel on caffeine! If you follow the steps carefully, your lathe will purr like a kitten. Happy turning!

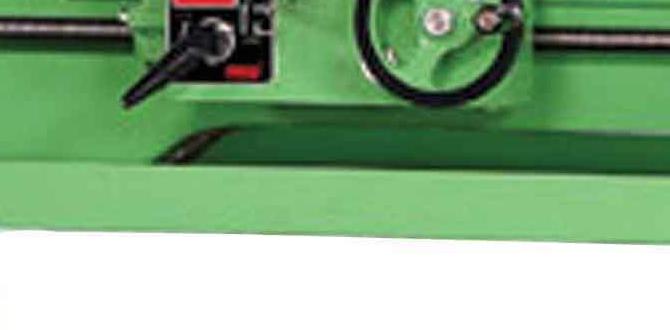

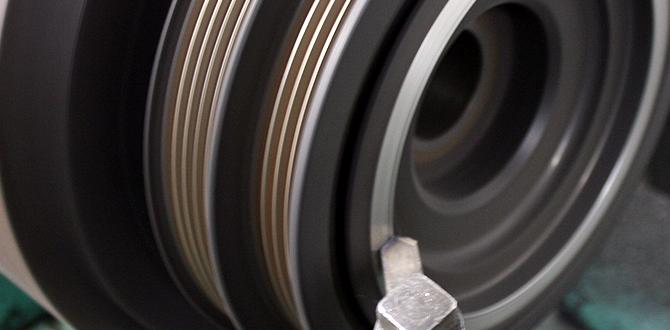

Understanding Pulley Systems in Metal Lathes

Explanation of how pulley systems affect lathe performance. Types of pulleys used in metal lathe setups.Pulley systems play a big role in how well a metal lathe works. They help control the speed and power of the machine. If your pulleys are in good shape, your lathe will run smoothly. There are two main types of pulleys: fixed pulleys, which help lift heavy things, and variable pulleys, which let you change speeds easily. It’s like choosing between cruising or racing on your bike! Regular checks can keep those pulleys turning like they should.

| Type of Pulley | Function |

|---|---|

| Fixed Pulley | Changes direction of force |

| Variable Pulley | Adjusts speed and torque |

Troubleshooting Common Wiring Issues

Common signs of wiring problems in metal lathes. Steps to diagnose and fix wiringrelated issues.Wiring problems in metal lathes can slow down your work. Look for signs like flickering lights or machines not running. These can mean bad connections. If you suspect an issue, follow these steps:

- Check the power source.

- Inspect wires for damage.

- Test connections for tightness.

- Use a multimeter to check voltage.

By watching for issues and fixing them quickly, you keep your lathe running smoothly.

What Are the Signs of Wiring Problems?

Common signs include burning smells, strange sounds, or unexpected machine stops. If you notice these, it’s time to check the wiring right away.

Upgrading Your Metal Lathe Wiring and Pulley System

Benefits of upgrading wiring for improved performance. Recommendations for advanced wiring techniques and pulley configurations.Improving your metal lathe wiring and pulley system can boost its performance. Modern wiring leads to better power flow. This means smoother operation and fewer disruptions. Upgrading your pulleys also helps. Better pulley configurations enhance speed and torque. Together, these upgrades make your lathe more efficient and reliable. Here are some key points to consider:

- Use thicker wires for less resistance.

- Consider a variable speed pulley system for flexibility.

- Check connections regularly to avoid failures.

- Opt for high-quality components for durability.

What are the benefits of upgrading your metal lathe wiring?

Upgrading wiring improves power efficiency and increases the life of your lathe. It also reduces the risk of overheating, which can damage parts and lead to costly repairs. A well-wired system supports high performance, making your projects easier and faster.

Maintenance Tips for Metal Lathe Wiring and Pulleys

Regular maintenance practices to ensure longevity. Signs that indicate the need for immediate maintenance or repair.Keeping your metal lathe wiring and pulleys in top shape is key for them to last long. Regular check-ups can save you from bigger problems down the road. Look for signs like strange noises or slipping belts. These mean it’s time to act! A bit like spotting a lizard on the wall before it jumps at you! Here’s a handy table to keep track of maintenance:

| Maintenance Task | Frequency |

|---|---|

| Inspect wiring | Monthly |

| Check pulleys for wear | Every 3 months |

| Lubricate moving parts | Every 6 months |

With a little effort, your lathe can run like a gazelle instead of an old turtle! Regular maintenance can save money and help everything run smoothly.

Resources for Further Learning

Recommended books, guides, and online courses. Community forums and expert organizations for ongoing support.Learning about lathe wiring can feel like a big, tangled mess at first, but fear not! There are plenty of resources to help you untwist that wire. You can dive into recommended books like “Metalworking for Dummies” or explore guides that break down complex topics. Online courses can be a goldmine of knowledge, guiding you step-by-step. Don’t forget about community forums; they’re like huge hangouts where experts share tips and tricks. And while you’re at it, check out the handy table below for some suggestions!

| Type | Resource |

|---|---|

| Books | Metalworking for Dummies |

| Online Course | Basic Lathe Operation |

| Forums | Lathe Lovers Community |

| Expert Org | American Machinists Association |

Conclusion

In summary, understanding lathe wiring and metal lathe pulleys is essential for successful machining. You’ve learned about their importance in powering your lathe effectively. Always check your wiring for safety, and ensure pulleys are in good condition. For more detailed tips, consider reading guides on lathe maintenance. This knowledge can help you become a better machinist!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Metal Lathe, And Pulley Systems:A lathe is a machine that shapes metal or wood. It spins the material while you cut it with a tool. We use pulleys to help move the lathe’s parts. The wiring connects the motor to power the lathe. This way, you can create different shapes easily!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Electrical Components Needed To Wire A Metal Lathe For Optimal Performance?To wire a metal lathe, you need a few key electrical parts. First, you need a power switch to turn it on and off. Next, a motor helps the lathe move and work on metal. You also need wires to connect everything together. Finally, a fuse protects your machine from too much electricity.

How Do Pulleys Affect The Speed And Torque Output Of A Metal Lathe?Pulleys are wheels that help us move things with ropes or belts. In a metal lathe, pulleys help change how fast it spins and how strong it is. When you use a bigger pulley, it makes the lathe spin slower but gives it more power, or torque. A smaller pulley makes it spin faster but with less power. So, pulleys help us get the right speed and strength for our work!

What Safety Precautions Should Be Taken When Wiring And Operating A Metal Lathe With A Pulley System?When using a metal lathe with a pulley system, always wear safety glasses to protect your eyes. Keep your clothes and hair away from moving parts to avoid getting caught. Make sure the machine is plugged into a safe power source with a good switch. Before starting, check that everything is secure and working well. Lastly, ask a grown-up to help if you’re unsure about anything!

How Can You Troubleshoot Electrical Issues Related To The Wiring Of A Metal Lathe?To troubleshoot electrical problems with a metal lathe, first, make sure it’s unplugged to stay safe. Check the power cord for any damage. Then, look at the connections to see if anything is loose or broken. You can also use a simple tool called a multimeter to test if electricity is reaching the lathe. If you’re unsure, ask an adult or a friend for help.

What Are The Advantages Of Using Variable Speed Pulleys In Metal Lathe Applications?Using variable speed pulleys on metal lathes gives us more control. We can make the machine go faster or slower. This helps when cutting different materials. It also helps us make better shapes and finish the work nicely. Overall, it makes our work easier and better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Metal Lathe, And Pulley Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a machine that shapes metal or wood. It spins the material while you cut it with a tool. We use pulleys to help move the lathe’s parts. The wiring connects the motor to power the lathe. This way, you can create different shapes easily!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Electrical Components Needed To Wire A Metal Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a few key electrical parts. First, you need a power switch to turn it on and off. Next, a motor helps the lathe move and work on metal. You also need wires to connect everything together. Finally, a fuse protects your machine from too much electricity.”}},{“@type”: “Question”,”name”: “How Do Pulleys Affect The Speed And Torque Output Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulleys are wheels that help us move things with ropes or belts. In a metal lathe, pulleys help change how fast it spins and how strong it is. When you use a bigger pulley, it makes the lathe spin slower but gives it more power, or torque. A smaller pulley makes it spin faster but with less power. So, pulleys help us get the right speed and strength for our work!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring And Operating A Metal Lathe With A Pulley System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a pulley system, always wear safety glasses to protect your eyes. Keep your clothes and hair away from moving parts to avoid getting caught. Make sure the machine is plugged into a safe power source with a good switch. Before starting, check that everything is secure and working well. Lastly, ask a grown-up to help if you’re unsure about anything!”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Electrical Issues Related To The Wiring Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot electrical problems with a metal lathe, first, make sure it’s unplugged to stay safe. Check the power cord for any damage. Then, look at the connections to see if anything is loose or broken. You can also use a simple tool called a multimeter to test if electricity is reaching the lathe. If you’re unsure, ask an adult or a friend for help.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Variable Speed Pulleys In Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using variable speed pulleys on metal lathes gives us more control. We can make the machine go faster or slower. This helps when cutting different materials. It also helps us make better shapes and finish the work nicely. Overall, it makes our work easier and better!”}}]}