Have you ever wondered how a metal lathe works? This amazing machine helps people create precise shapes from metal. But what makes it even more interesting is the lathe wiring and the quick change tool post. These parts put creativity at the heart of metalworking.

Imagine you want to make a custom metal part. You step up to the lathe, and you need the right tools for the job. That’s where the quick change tool post comes in! It lets you swap tools quickly. This saves time and makes your work easier. Who doesn’t want to work faster?

Fun fact: Did you know that early lathes were operated by hand? Nowadays, they are much more advanced with amazing wiring systems. The wiring connects the various parts, allowing the machine to run smoothly. Understanding lathe wiring might seem tricky, but it is key to unlocking the full potential of your lathe.

In this article, we’ll explore the magic of lathe wiring and the benefits of a quick change tool post. By the end, you’ll see why these components are essential for every metalworking enthusiast!

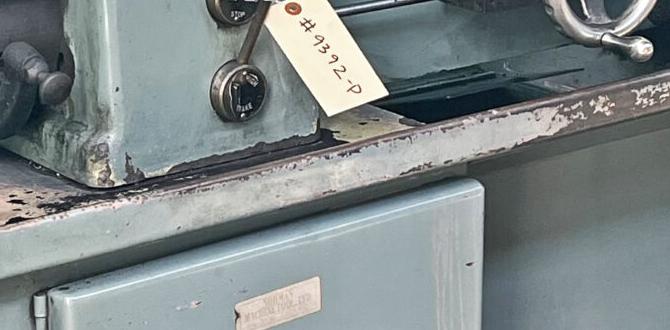

Lathe Wiring: Metal Lathe Quick Change Tool Post Setup Guide

Lathe Wiring Metal Lathe Quick Change Tool Post

Imagine working on a project with a metal lathe that has a quick change tool post. This feature allows you to switch tools quickly, making your work faster and more efficient. The right lathe wiring ensures everything operates smoothly. You’ll discover how simple wiring connections can help maintain power and safety. Plus, learning how to set up your tools can transform your crafting experience. Embrace this handy tool for your next project!Choosing the Right Quick Change Tool Post

Benefits of using a quick change tool post. Factors to consider when selecting a tool post for your lathe.Using a quick change tool post can turn your lathe into a magic machine! It lets you switch tools fast, saving time and keeping your projects moving. Imagine not hunting for the right tool like it’s hide-and-seek!

When picking a tool post, consider size, strength, and how easy it is to attach. Make sure it fits your lathe. A tool post that’s too big or too small is like wearing shoes that don’t fit—it’s just uncomfortable!

| Factor | Importance |

|---|---|

| Size | Must match your lathe |

| Durability | Lasts longer and works better |

| Ease of Use | Faster tool changes mean more fun! |

Remember, a good tool post is like a trusty sidekick—it helps you get the job done better!

Step-by-Step Guide to Wiring Your Metal Lathe

Required tools and materials for wiring. Detailed wiring instructions with diagrams.Wiring your metal lathe can be fun and easy. First, gather your tools: a screwdriver, wire cutters, a voltage tester, and a wrench. You will also need wires, terminals, and a diagram of your lathe. Follow these steps carefully:

- Read the lathe manual; it has important wiring details.

- Turn off all power before starting.

- Connect the wires according to your diagram.

- Double-check all connections.

- Turn on the power and test your lathe.

What tools do I need for wiring a metal lathe?

You need a screwdriver, wire cutters, a voltage tester, and a wrench.Common Wiring Issues and Troubleshooting

Identifying common electrical problems. Solutions and best practices for wiring troubleshooting.Wiring issues can feel like solving a puzzle with missing pieces. Common problems include shorts, loose connections, and burnt fuses. These troubles can stop your metal lathe in its tracks, kind of like running out of snacks during a movie! To troubleshoot, check for frayed wires and ensure all connections are snug. A quick fix could be tightening screws or replacing fuses. Always follow safety steps—safety first, snack second!

| Common Issues | Solutions |

|---|---|

| Short Circuits | Look for damaged wires. |

| Loose Connections | Tighten all connections. |

| Burnt Fuses | Replace with the correct type. |

Upgrading Your Lathe with Advanced Features

Optional electrical upgrades to enhance lathe performance. Integrating digital controls into your metal lathe setup.Upgrading your lathe can turn a simple machine into a superhero! Adding electrical upgrades can make your lathe run smoother and do tricks. Digital controls will help you get precise cuts without breaking a sweat. With just a few buttons, you can control speed and power. Plus, you’ll look super cool while doing it! Let’s dive into the fun world of lathe upgrades!

| Upgrade | Benefit |

|---|---|

| Digital Controls | Improved precision and ease of use |

| Variable Speed Drive | Adjustable speeds for different materials |

| Automatic Tool Changer | Saves time and effort |

Maintenance Tips for Longevity of Lathe Wiring

Routine checks to ensure wiring integrity. Cleaning and caring for wiring and electrical components.Taking care of your lathe wiring is important for its long life. Begin with routine checks to make sure everything is working well. Look for any damage or loose connections. Regular cleaning helps too. Dust and grime can cause issues. Follow these tips:

- Check wires for wear and tear.

- Keep contacts clean and tight.

- Use a soft cloth to wipe connections.

These simple steps can keep your lathe running smoothly for years!

How can I maintain my metal lathe’s wiring?

To maintain your lathe’s wiring, check connections and clean regularly. Check for damage and keep surfaces dust-free. Regular upkeep helps avoid problems and ensures safe operation.

Resources for Further Learning

Recommended books, websites, and forums for lathe enthusiasts. Online video tutorials for practical demonstrations.Learning about lathe wiring can be fun and exciting! There are many resources to help you. Books like “The Complete Guide to Lathes” are treasure troves of information. Websites like MachinistsWeb offer forums where you can ask questions and share tips with other enthusiasts. And don’t forget online video tutorials—watching someone wire a tool post makes it feel like you’re right there! Want to know what to explore? Here’s a quick table:

| Resource Type | Recommended Resource |

|---|---|

| Books | The Complete Guide to Lathes |

| Websites | MachinistsWeb |

| Video Tutorials | YouTube |

These will make you a lathe pro in no time! Who knew learning could be this much fun? Get started today!

Conclusion

In summary, a lathe wiring for a metal lathe makes your projects easier and faster. A quick change tool post saves time by letting you swap tools quickly. Remember to follow safety rules while working. You can explore more about tool posts and wiring techniques online. Start experimenting with your metal lathe today for better projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Quick Change Tool Posts For Metal Lathes:Sure! A lathe is a machine that spins metal to shape it. Wiring a lathe helps it work safely and properly. Quick change tool posts let you switch tools fast. This saves time when you need different tools. Always follow safety rules when using a lathe!

Sure! Please provide the question you’d like me to answer.

What Are The Basic Electrical Requirements For Wiring A Metal Lathe, And How Do They Vary Based On The Lathe’S Size And Motor Type?To wire a metal lathe, you need to connect it to electricity safely. First, check the size of the lathe and its motor type. Smaller lathes usually need less power and can often run on regular outlets. Bigger lathes with heavy motors might need special outlets and more power. Always follow safety rules when working with electricity!

How Do You Install A Quick Change Tool Post On A Metal Lathe, And What Are The Key Factors To Consider During The Installation Process?To install a quick change tool post on a metal lathe, first, turn off the lathe and remove the old tool holder. Clean the area where the new tool post will go. Then, place the quick change tool post on the lathe and tighten it down. Make sure it’s level and secure before adding your tools. Remember to check the tool height and adjust it so it cuts properly.

What Safety Precautions Should Be Taken When Wiring A Metal Lathe To Ensure Proper Functioning And Prevent Electrical Hazards?When wiring a metal lathe, we need to be careful. First, always turn off the power before starting. Next, make sure all wires are in good shape and not damaged. We should also connect the lathe to a grounded outlet. This helps prevent shocks. Lastly, wear rubber-soled shoes to keep safe while working.

How Does The Use Of A Quick Change Tool Post Improve Efficiency In Machining Operations Compared To Traditional Tool Holders?A quick change tool post lets you swap tools much faster than using traditional tool holders. This means you spend less time changing tools and more time working on your project. You can easily switch between different tasks without slowing down. So, you can finish your work quicker and have more time to do other things!

What Are The Common Troubleshooting Steps For Electrical Issues In A Metal Lathe, Particularly Related To Motor Controls And Wiring?If your metal lathe isn’t working right, here’s what you can do. First, check the power supply. Make sure it’s plugged in and the outlet works. Next, look for loose or damaged wires. Tighten any loose connections and replace broken wires. Finally, check the motor controls. Reset them if needed and see if that fixes the problem.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Quick Change Tool Posts For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to shape it. Wiring a lathe helps it work safely and properly. Quick change tool posts let you switch tools fast. This saves time when you need different tools. Always follow safety rules when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Basic Electrical Requirements For Wiring A Metal Lathe, And How Do They Vary Based On The Lathe’S Size And Motor Type?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need to connect it to electricity safely. First, check the size of the lathe and its motor type. Smaller lathes usually need less power and can often run on regular outlets. Bigger lathes with heavy motors might need special outlets and more power. Always follow safety rules when working with electricity!”}},{“@type”: “Question”,”name”: “How Do You Install A Quick Change Tool Post On A Metal Lathe, And What Are The Key Factors To Consider During The Installation Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a quick change tool post on a metal lathe, first, turn off the lathe and remove the old tool holder. Clean the area where the new tool post will go. Then, place the quick change tool post on the lathe and tighten it down. Make sure it’s level and secure before adding your tools. Remember to check the tool height and adjust it so it cuts properly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe To Ensure Proper Functioning And Prevent Electrical Hazards?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, we need to be careful. First, always turn off the power before starting. Next, make sure all wires are in good shape and not damaged. We should also connect the lathe to a grounded outlet. This helps prevent shocks. Lastly, wear rubber-soled shoes to keep safe while working.”}},{“@type”: “Question”,”name”: “How Does The Use Of A Quick Change Tool Post Improve Efficiency In Machining Operations Compared To Traditional Tool Holders?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post lets you swap tools much faster than using traditional tool holders. This means you spend less time changing tools and more time working on your project. You can easily switch between different tasks without slowing down. So, you can finish your work quicker and have more time to do other things!”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps For Electrical Issues In A Metal Lathe, Particularly Related To Motor Controls And Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe isn’t working right, here’s what you can do. First, check the power supply. Make sure it’s plugged in and the outlet works. Next, look for loose or damaged wires. Tighten any loose connections and replace broken wires. Finally, check the motor controls. Reset them if needed and see if that fixes the problem.”}}]}