Have you ever watched a lathe spin and create something amazing? Lathes are powerful machines that shape metal and other materials. To get the best results, it’s super important to have the right workholding setup.

Choosing the best metal lathe can feel overwhelming. There are so many options! How do you know which one is perfect for your needs? The answer lies in understanding how workholding affects your projects.

Imagine trying to carve out a beautiful design on a spinning piece of metal, but it keeps slipping. Frustrating, right? That’s why great workholding is key. It keeps your material steady, allowing for precise cuts and beautiful shapes.

In this article, we will explore the best workholding methods for metal lathes. Whether you’re a beginner or an expert, knowing the right techniques can change your craft. Let’s dive in and discover how to make your lathe work even better!

Lathe Workholding: Discover The Best Metal Lathe Techniques

Lathe Workholding: Best Metal Lathe Options

Choosing the best metal lathe can greatly improve your projects. A good lathe holds your workpiece firmly, preventing slips and mistakes. Many options exist, from manual to CNC models. Each type offers different benefits based on your needs. Did you know that some lathes can shape metal into intricate designs like jewelry? Understanding workholding methods helps you make the right choice for precision and ease. Discover how the right lathe can change your crafting experience!Key Factors to Consider When Choosing a Metal Lathe

Size and capacity considerations for workpieces. Types of metals and materials suitable for different lathes.Choosing the right metal lathe can be tricky. First, think about the size of the workpieces you want to create. A bigger lathe handles larger materials, while smaller lathes are great for tiny projects. Next, consider the types of metals you’ll use. Some lathes cut softer materials like aluminum, while others work best with tougher metals like steel.

- Bigger lathes for big projects

- Smaller lathes for tiny tasks

- Soft metals: use lighter lathes

- Tough metals: need heavy-duty lathes

What is the best metal for a lathe?

The best metal for your lathe depends on what you make. Soft metals like aluminum are easy to work with. But for hard work, steel or titanium is better.

Popular Workholding Devices for Metal Lathes

Chuck types: threejaw vs. fourjaw chucks. Collet systems: advantages and applications. Tailstock and steady rest: enhancing stability.Choosing the right workholding device makes a big difference when using a metal lathe. First, let’s chat about chucks! Three-jaw chucks are quick and easy for round pieces, while four-jaw chucks let you grab those tricky shapes better. Then we have collet systems. They hold tools tightly, which is great for accuracy. They’re like that friend who always keeps things in line! With tailstocks and steady rests, your work becomes rock steady. Stability is key, especially when your project is going for a spin!

| Device | Advantages |

|---|---|

| Three-Jaw Chuck | Quick setup for round work |

| Four-Jaw Chuck | Handles various shapes |

| Collet System | Precision and grip |

| Tailstock | Supports longer pieces |

| Steady Rest | Boosts stability during cuts |

Advanced Workholding Techniques

Use of various fixtures and jigs for precision work. Techniques for holding irregularly shaped parts effectively.For perfect precision in metal lathe work, using fixtures and jigs is key. These tools help hold parts securely, like a firm grip on your favorite toy—no accidental drops here! Fixtures give consistent shapes, while jigs help guide tools for accuracy. When you’re working with quirky or oddly shaped pieces, special techniques come into play. Think of holding a slice of pizza without making a mess. You need to hold it just right! Here’s a quick look at some advanced methods:

| Technique | Use Case |

|---|---|

| Vice Clamps | Best for flat parts |

| Magnetic Bases | Useful for small, metallic pieces |

| Custom Jigs | Perfect for unique shapes |

With the right techniques, even the craziest shapes can be held steady. Remember to keep things light—like a feather on a tightrope!

Safety Considerations in Lathe Workholding

Best practices to avoid accidents during lathe operations. Importance of proper setup and maintenance for safety.Working with a lathe can be fun, but safety should always come first! Proper setup is like a good taco stand—it makes everything smoother. Make sure your workpiece is secure and check for tools that might be loose. Keep your workspace tidy; no one wants to trip over a rogue wrench! Remember, a little maintenance goes a long way. Check those belts and switches regularly. Safety is no accident, just like your favorite ice cream flavor—choose wisely!

| Best Practices for Lathe Safety | Importance |

|---|---|

| Secure workpieces | Prevents accidents |

| Regular maintenance | Ensures proper function |

| Keep workspace tidy | Reduces trip hazards |

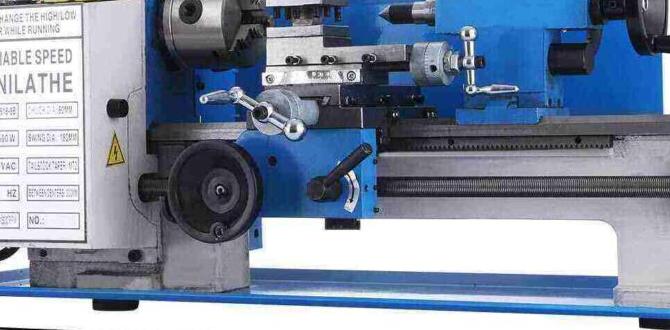

Comparison of Top Metal Lathes for Workholding

Review of leading metal lathe models available in the market. Evaluation of workholding features and user feedback.Finding the best metal lathe for workholding can feel like searching for a unicorn. Not impossible, but challenging! Some top models to consider include the Grizzly G0602 and the Jet G0602. These lathes have impressive workholding features like sturdy chucks and easy adjustments. Users rave about their reliability and precision.

| Model | Workholding Features | User Feedback |

|---|---|---|

| Grizzly G0602 | Sturdy 5-inch chuck, quick-change tooling | Highly rated for durability |

| Jet G0602 | Variable speed control, excellent grip | Praised for ease of use |

These options give you a solid mix of performance and user satisfaction, making them top picks for metal lathe workholding!

Maintenance Tips for Longevity of Workholding Systems

Routine checks to ensure optimal performance. Cleaning and lubrication guidelines to prolong lifespan.To keep workholding systems in top shape, do regular checks. Look for wear or damage often. Clean the parts after use to avoid buildup. Lubricate moving parts to keep them smooth. These simple steps can make your systems last longer.

- Inspect regularly for any issues.

- Wipe down parts to remove dust and debris.

- Apply lubricant where needed to prevent rust.

What routine checks should I perform?

Look for worn-out parts or any signs of damage. Check if everything moves freely. This helps improve safety and performance.

How often should I clean and lubricate?

Try to clean and lubricate your systems after every use. Regular maintenance keeps them running well and extends their lifespan.

Conclusion

In summary, choosing the best metal lathe is crucial for successful lathe workholding. Consider factors like size, material, and features. Make sure to select a sturdy workholding system for accuracy and safety. We encourage you to explore more about different lathe types and accessories. Start your journey in metalworking today, and you’ll create amazing projects!FAQs

What Are The Best Types Of Chucks To Use For Maximum Gripping Power In Metal Lathe Workholding?The best types of chucks for metal lathes are three-jaw chucks and four-jaw chucks. Three-jaw chucks grip round pieces well and are easy to use. Four-jaw chucks are good for holding different shapes tightly. Both types give you strong grip and do good work!

How Do You Choose The Right Workholding Fixture For Different Types Of Materials Being Machined On A Metal Lathe?To choose the right workholding fixture for different materials, you first think about how hard the material is. Softer materials like plastic can use simple clamps. Harder metals need stronger, more secure fixtures. You also check the shape of the part. If it’s round, a chuck is good. If it’s flat, a vice might work better. Always make sure the part is held tight, so it doesn’t move while you machine it.

What Are The Advantages And Disadvantages Of Using A Collet Versus A Three-Jaw Chuck In Lathe Operations?Using a collet holds your work piece very tightly and gives you better accuracy. This is great for small parts. However, collets work with only specific sizes. A three-jaw chuck is more flexible and can hold many shapes and sizes, but it might not hold as tightly as a collet. So, if you need precision, choose a collet; for variety, pick a three-jaw chuck.

How Can Effective Workholding Improve The Precision And Accuracy Of Parts Produced On A Metal Lathe?Effective workholding keeps the metal piece steady while the lathe works. When you hold the part well, it doesn’t move around. This helps create smooth and exact shapes. Good workholding means we get better results every time we use the lathe. It makes sure our parts fit perfectly in whatever they are used for.

What Accessories Can Enhance The Versatility Of Workholding Setups In Metal Lathe Operations?You can use different accessories to make workholding setups better for metal lathes. A chuck, which holds the metal pieces, can grip various shapes and sizes. V-blocks help hold round objects steady. You might also use clamps to secure parts firmly. These tools let you do more kinds of work easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Types Of Chucks To Use For Maximum Gripping Power In Metal Lathe Workholding? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best types of chucks for metal lathes are three-jaw chucks and four-jaw chucks. Three-jaw chucks grip round pieces well and are easy to use. Four-jaw chucks are good for holding different shapes tightly. Both types give you strong grip and do good work!”}},{“@type”: “Question”,”name”: “How Do You Choose The Right Workholding Fixture For Different Types Of Materials Being Machined On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right workholding fixture for different materials, you first think about how hard the material is. Softer materials like plastic can use simple clamps. Harder metals need stronger, more secure fixtures. You also check the shape of the part. If it’s round, a chuck is good. If it’s flat, a vice might work better. Always make sure the part is held tight, so it doesn’t move while you machine it.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Collet Versus A Three-Jaw Chuck In Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet holds your work piece very tightly and gives you better accuracy. This is great for small parts. However, collets work with only specific sizes. A three-jaw chuck is more flexible and can hold many shapes and sizes, but it might not hold as tightly as a collet. So, if you need precision, choose a collet; for variety, pick a three-jaw chuck.”}},{“@type”: “Question”,”name”: “How Can Effective Workholding Improve The Precision And Accuracy Of Parts Produced On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Effective workholding keeps the metal piece steady while the lathe works. When you hold the part well, it doesn’t move around. This helps create smooth and exact shapes. Good workholding means we get better results every time we use the lathe. It makes sure our parts fit perfectly in whatever they are used for.”}},{“@type”: “Question”,”name”: “What Accessories Can Enhance The Versatility Of Workholding Setups In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use different accessories to make workholding setups better for metal lathes. A chuck, which holds the metal pieces, can grip various shapes and sizes. V-blocks help hold round objects steady. You might also use clamps to secure parts firmly. These tools let you do more kinds of work easily.”}}]}