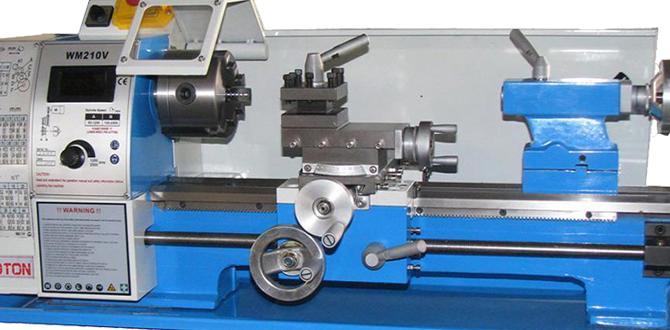

Have you ever wondered how metal is shaped into complex parts? It’s a fascinating process that often starts with lathe workholding. A metal lathe is a powerful tool that spins the material. This allows you to carve, shape, and finish it just the way you want.

When you think of a lathe, what comes to mind? Many people picture a simple machine without realizing all the cool accessories that can enhance its use. These lathe accessories can help make your work easier and more precise. Imagine having the right tool to hold your work piece firmly in place.

For example, did you know that using the proper workholding helps prevent mistakes? It can make all the difference between a perfect cut and a ruined project. With the right metal lathe accessories, even beginners can achieve impressive results. So, are you ready to learn more about how to make the most of your metal lathe?

Essential Lathe Workholding: Must-Have Metal Lathe Accessories

Lathe Workholding and Metal Lathe Accessories

Lathe workholding is key for precision in metalworking. It keeps your material stable while you shape it. There are various accessories to enhance your lathe’s capabilities, like chucks, tailstocks, and steady rests. Did you know that the right workholding setup can significantly improve your project’s accuracy? Using quality accessories can prevent mistakes and ensure a smoother operation. Explore these tools to elevate your lathe experience and create better projects!Understanding Workholding in Metal Lathe Operations

Definition and importance of workholding in machining.. Common challenges faced without proper workholding solutions..Workholding is like a superhero for metal lathes. It holds your material steady while you shape it into something amazing. Without good workholding, you’ll face problems like tools skidding off or uneven cuts. Imagine trying to ice skate on a bumpy road! That’s why workholding is super important in machining. It keeps everything in place, so you can create perfect pieces without any drama. Here’s a quick look at common challenges:

| Challenge | Description |

|---|---|

| Slipping Material | Material may move, causing inaccurate cuts. |

| Wobbling | Uneven support leads to blurry cuts. |

| Safety Hazards | Loose materials can be dangerous for operators. |

Popular Accessories for Enhanced Lathe Workholding

Discussion on essential accessories such as faceplates, steady rests, and riser blocks.. How these accessories improve precision and efficiency..Using the right accessories can transform your lathe experience from “meh” to “wow!” Faceplates are a must-have. They hold your work solidly while you spin away. Steady rests give support, which means fewer wobbles and more finesse. And, if you’re feeling fancy, riser blocks can help with those tricky jobs that need a little extra lift. Together, these tools boost your precision and efficiency, making every project smooth sailing. Why work harder when you can work smarter?

| Accessory | Benefit |

|---|---|

| Faceplates | Hold work securely |

| Steady Rests | Reduce wobble |

| Riser Blocks | Provide extra height |

Choosing the Right Chuck for Your Metal Lathe

Explanation of different chuck types (threejaw, fourjaw, and hydraulic).. Factors to consider when selecting a chuck based on the workpiece..Choosing the right chuck is key for lathe work. There are several types to consider. A three-jaw chuck holds round pieces well and is easy to use. The four-jaw chuck is great for square or uneven shapes, as you can adjust each jaw separately. Finally, a hydraulic chuck provides strong grip and quick adjustments, making it ideal for busy shops.

When selecting a chuck, think about:

- The shape of your workpiece.

- How much grip you need.

- Your experience level with chucks.

What factors should I consider when choosing a chuck?

Consider the shape and size of your workpiece. You should also think about how fast you need to change pieces and your own skill with tools.

Collets: Versatility and Precision in Workholding

Analysis of types of collet systems and their applications.. Benefits of using collets over traditional chucks..Collets are special tools for holding workpieces on a lathe. They securely grip items using a clamping action. There are different types of collet systems, like compression collets and hex collets. Each has unique uses in various projects. Here’s why collets are great:

- They provide more precision than traditional chucks.

- Collets are easy to change, saving time.

- They offer better grip, reducing vibration.

Using collets can make your lathe work smoother and more efficient!

What are the benefits of using collets?

Collets hold workpieces tightly and accurately. They help to make cleaner cuts. Collets can increase your project’s overall quality. This way, you can be proud of your work!

Types of Collet Systems

- Compression Collets

- Hex Collets

- Dowel Collets

Step Blocks and Fixtures for Customized Workholding

Description of step blocks and their role in secure workholding.. Examples of custom fixtures to improve automation and precision..Step blocks are small, sturdy tools that help hold your workpiece securely while using a lathe. Think of them as the loyal friend who never lets you drop your ice cream. They come in various sizes to fit different jobs. Custom fixtures improve both automation and precision. These could be special clamps or holders that fit your specific task perfectly, making work easier and faster. Who wouldn’t want to be a speedy lathe wizard?

| Type | Description |

|---|---|

| Step Blocks | Used for adjustable height and stable support. |

| Custom Fixtures | Tailored clamps designed for specific parts. |

| Automation Aids | Tools that help in speedy and precise operations. |

Maintenance Tips for Lathe Workholding Accessories

Best practices for maintaining chucks, collets, and other accessories.. Signs that indicate when workholding accessories need replacement..Keeping your lathe workholding accessories in great shape is key for smooth operation. Regular maintenance helps to avoid issues later. Here are some best practices:

- Clean chucks and collets after each use.

- Lubricate moving parts regularly.

- Check for wear and tear frequently.

Watch for signs that mean it’s time for a replacement. If you see any cracks, rust, or poor gripping power, it’s best to replace them. These small steps can keep your accessories lasting longer and working better.

How can I tell if my accessories need replacing?

Look for visible damage like cracks or rust. Check for poor gripping as well. If they fail to hold materials securely, it’s time for a new one.

Conclusion

In conclusion, lathe workholding and metal lathe accessories are key for successful projects. They help keep materials secure, ensuring safety and precision. You can explore various tools like chucks and vises to enhance your skills. Start by practicing with simple projects. For more tips and tricks, check out additional resources and books on lathe work. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Accessories For Metal Lathes:Sure! When using a lathe, we need ways to hold the metal pieces we work on. This is called workholding. We can use different tools, like chucks or clamps, to keep the metal steady. Accessories, like tool holders, help us use different cutting tools. With the right workholding and accessories, we can make better shapes and cuts in the metal.

Sure! Just let me know the question you want me to answer.

What Are The Different Types Of Chucks Used For Workholding On A Metal Lathe, And How Do They Differ In Application?There are three main types of chucks we use on a metal lathe: three-jaw, four-jaw, and collet chucks. A three-jaw chuck grips round objects well and is easy to use. A four-jaw chuck can hold square or odd-shaped pieces better, but it’s trickier to set up. Collet chucks are great for holding small, cylindrical items tightly, making them perfect for precise work. Each type helps us work with different shapes and sizes of materials.

How Can A Tailstock Be Utilized To Enhance Precision And Stability During Machining Operations On A Metal Lathe?You can use a tailstock on a metal lathe to hold your metal piece tightly. This keeps it stable while you work. When the metal is steady, you can make cleaner and more precise cuts. It helps prevent mistakes and makes your work look better. Overall, the tailstock helps you do a great job!

What Are The Advantages Of Using A Four-Jaw Chuck Compared To A Three-Jaw Chuck In Lathe Workholding?A four-jaw chuck holds things more securely than a three-jaw chuck. You can adjust each jaw separately. This means you can grip different shapes better, like squares or irregular objects. It also helps you fix something that isn’t perfectly centered. This makes your work more accurate!

How Can You Ensure The Proper Alignment And Centering Of Workpieces When Using A Metal Lathe And Its Accessories?To align and center workpieces on a metal lathe, you should first check that the workpiece is securely held. Use a tailstock, which supports the other end, to help center it. Always look through a center hole to see if it lines up straight. You can also use a dial indicator to measure any wobbles. Take your time to make sure everything is just right!

What Are Some Essential Lathe Accessories That Can Improve Productivity And Accuracy During Metalworking Projects?Some important lathe accessories are tool holders, chuck keys, and calipers. Tool holders keep your tools in place and make changing them easier. Chuck keys help you tighten or loosen the chuck, which holds your metal piece. Calipers measure things accurately, so you get the right size every time. Using these tools can make your work faster and more precise.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Accessories For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe, we need ways to hold the metal pieces we work on. This is called workholding. We can use different tools, like chucks or clamps, to keep the metal steady. Accessories, like tool holders, help us use different cutting tools. With the right workholding and accessories, we can make better shapes and cuts in the metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Chucks Used For Workholding On A Metal Lathe, And How Do They Differ In Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are three main types of chucks we use on a metal lathe: three-jaw, four-jaw, and collet chucks. A three-jaw chuck grips round objects well and is easy to use. A four-jaw chuck can hold square or odd-shaped pieces better, but it’s trickier to set up. Collet chucks are great for holding small, cylindrical items tightly, making them perfect for precise work. Each type helps us work with different shapes and sizes of materials.”}},{“@type”: “Question”,”name”: “How Can A Tailstock Be Utilized To Enhance Precision And Stability During Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a tailstock on a metal lathe to hold your metal piece tightly. This keeps it stable while you work. When the metal is steady, you can make cleaner and more precise cuts. It helps prevent mistakes and makes your work look better. Overall, the tailstock helps you do a great job!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Four-Jaw Chuck Compared To A Three-Jaw Chuck In Lathe Workholding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A four-jaw chuck holds things more securely than a three-jaw chuck. You can adjust each jaw separately. This means you can grip different shapes better, like squares or irregular objects. It also helps you fix something that isn’t perfectly centered. This makes your work more accurate!”}},{“@type”: “Question”,”name”: “How Can You Ensure The Proper Alignment And Centering Of Workpieces When Using A Metal Lathe And Its Accessories?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and center workpieces on a metal lathe, you should first check that the workpiece is securely held. Use a tailstock, which supports the other end, to help center it. Always look through a center hole to see if it lines up straight. You can also use a dial indicator to measure any wobbles. Take your time to make sure everything is just right!”}},{“@type”: “Question”,”name”: “What Are Some Essential Lathe Accessories That Can Improve Productivity And Accuracy During Metalworking Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some important lathe accessories are tool holders, chuck keys, and calipers. Tool holders keep your tools in place and make changing them easier. Chuck keys help you tighten or loosen the chuck, which holds your metal piece. Calipers measure things accurately, so you get the right size every time. Using these tools can make your work faster and more precise.”}}]}